Preceding material for pumping

a technology of pre-mixed materials and pre-mixed concrete, which is applied in the direction of climate sustainability, solid waste management, sustainable waste treatment, etc., can solve the problems of clogging, inevitable and complicated mixing of water and cement, and the delivery end of the pumping, so as to achieve effective separation from the pumped ready-mixed concrete, prolong the pumping distance, and utilize waste effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

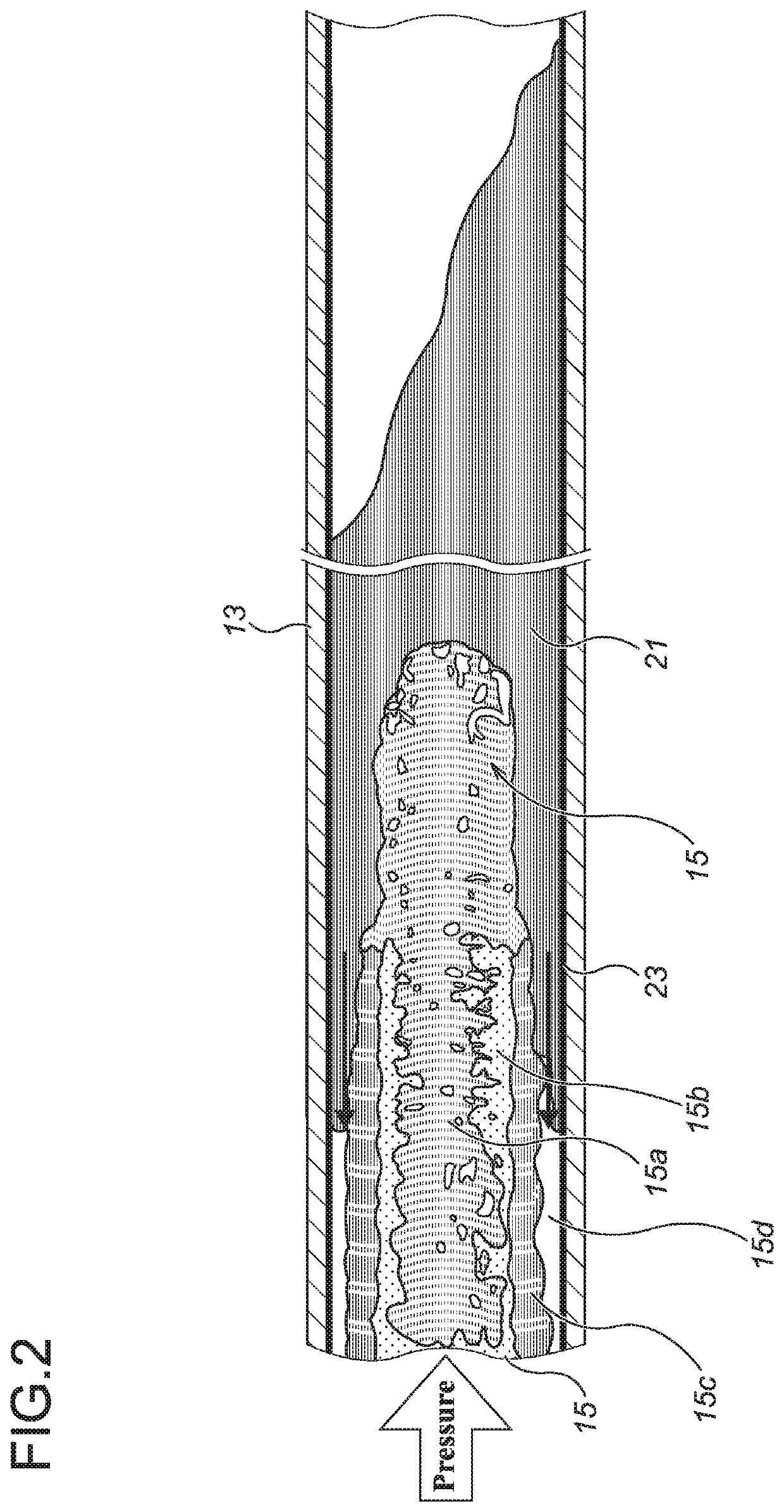

[0034]Now, an embodiment of the present invention will be explained with reference to FIG. 1 to FIG. 8. FIG. 1 is a view showing a state that ready-mixed concrete is pumped to and casted in a destined place by a ready-mixed concrete pumping vehicle 1, wherein a squeeze-type pump 5 and a hopper 7 are installed on a vehicle main body 3 of the ready-mixed concrete pumping vehicle 1. Moreover, an extendible boom 9 is installed on the vehicle main body 3. The boom 9 comprises a plurality of arms 11, etc.

[0035]A piping 13 is connected to the pump 5, and the piping 13 comprises a plurality of steel pipes, of which head has a flexible synthetic rubber hose connected thereto, so as to be extended to a destined place along the boom 9.

[0036]For reference, depending on the type of site, the steel pipes may further be extended beyond the head of the boom 9, by connecting additional steel pipes.

[0037]Ready-mixed concrete 15 (as illustrated in FIG. 2) is fed into the hopper 7, from a ready-mixed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com