Plated steel sheet for hot stamping, method of manufacturing plated steel sheet for hot stamping, method of manufacturing hot-stamped component, and method of manufacturing vehicle

a technology of hot stamping and plated steel, which is applied in the direction of heat treatment apparatus, superimposed coating process, furnace, etc., can solve the problems of reducing the weight of the steel sheet, reducing the processing itself, and preventing the possibility of reducing the weight of the vehicle body. , to achieve the effect of suppressing the occurren

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0154]The disclosure will be further described with reference to Examples. The disclosure is not limited to the following embodiments.

examples 1 to 4

, Comparative Examples 5 to 6

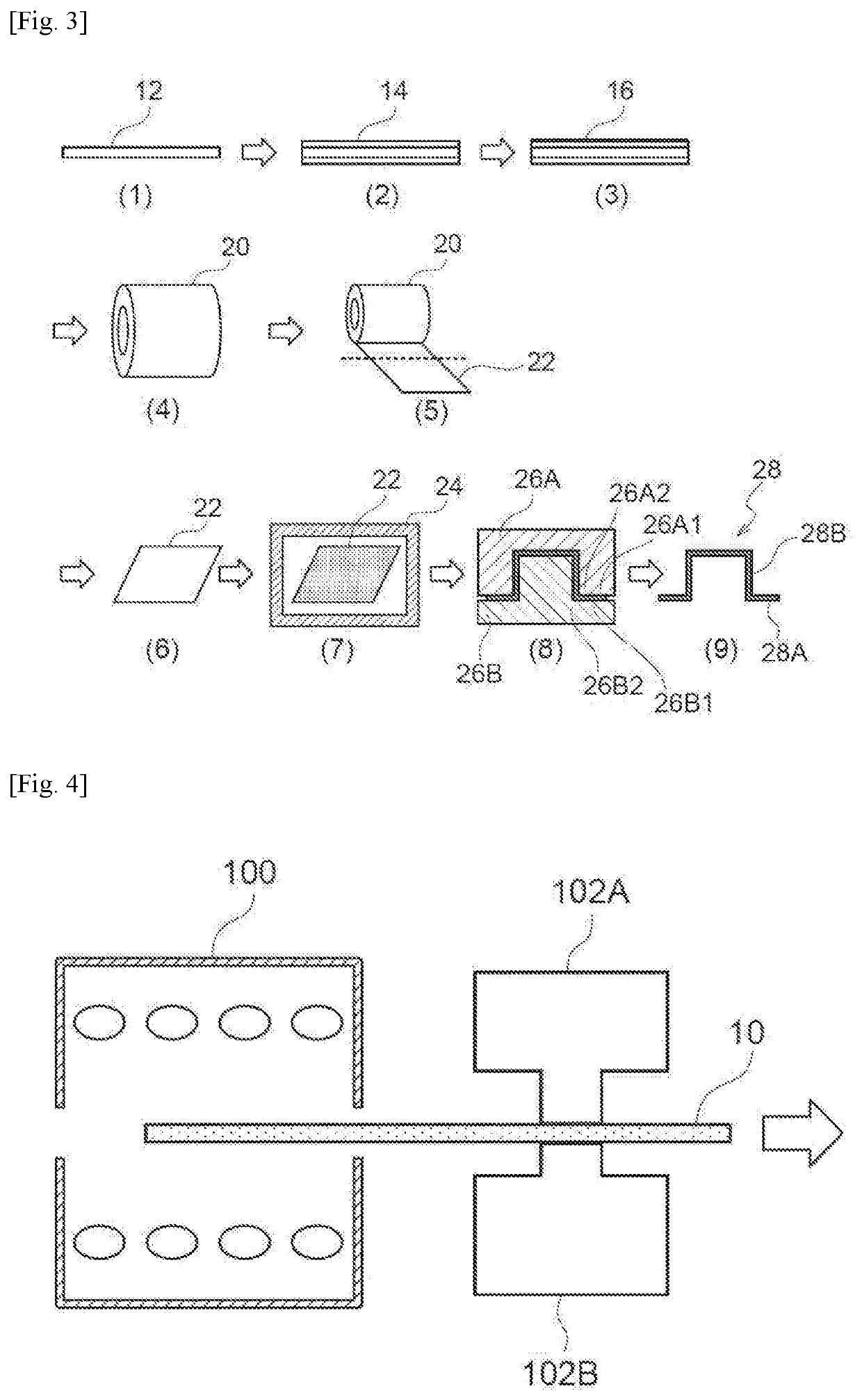

[0156]Both sides of a cold-rolled steel sheet having a thickness shown in Table 1 (based on % by mass, C: 0.21%, Si: 0.12%, Mn: 1.21%, P: 0.02%, S: 0.012%, Ti: 0.02%, B: 0.03%, Al: 0.04%, and the balance: Fe and impurities) were Al plated by a Sendzimir process. The annealing temperature was about 800° C., an Al plating bath contained 9% Si and further contained Fe eluted from the cold-rolled steel sheet. The Al basis weight after plating was adjusted by a gas wiping method, the Al basis weight per one side shown in Table 1 was obtained, and the sheet was then cooled. Thereafter, a chemical solution (nanotek slurry manufactured by C. I. Kasei Co., Ltd., particle size of zinc oxide particles=70 nm) was coated on the Al plating layer thus formed with a roll coater and baked at about 80° C., and a ZnO film having an adhesion amount (based on Zn amount) shown in Table 1 was formed. Next, zinc bis-octanoate (Zn-OCTOATE 22% solvent-free “manufactured by DIC Co...

examples 5 to 8

, Comparative Examples 7 to 8

[0157]Both sides of a cold-rolled steel sheet having a thickness shown in Table 1 (based on % by mass, C: 0.21%, Si: 0.12%, Mn: 1.21%, P: 0.02%, S: 0.012%, Ti: 0.02%, B: 0.03%, Al: 0.04%, and the balance: Fe and impurities) were Al plated by a Sendzimir process. The annealing temperature was about 800° C., an Al plating bath contained 9% Si and further contained Fe eluted from the cold-rolled steel sheet. The Al basis weight after plating was adjusted by a gas wiping method, the Al basis weight per one side shown in Table 1 was obtained, and the sheet was then cooled. Thereafter, zinc bis-octanoate (“Zn-OCTOATE 22% solvent-free” manufactured by DIC Corporation) as zinc-based metal soap was coated on the Al plating layer thus formed with a roll coater, and a zinc-based metal soap film having an adhesion amount shown in Table 1 was formed. In this way, a test material of a plated steel sheet was obtained.

[0158]

[0159]Characteristics of the test material of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com