Method for thermo-chemical energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

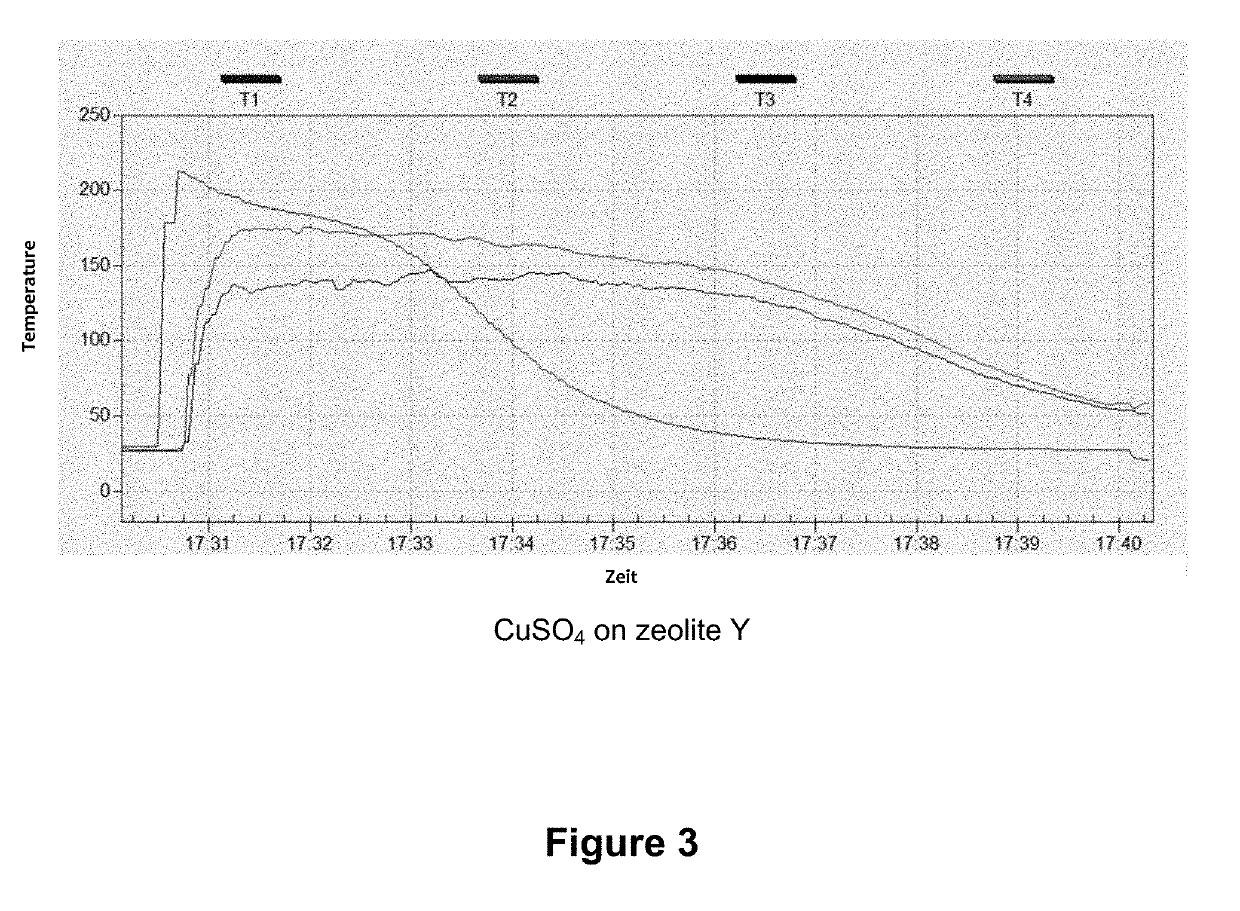

[0031]In a typical loading experiment, 50 g of zeolite Y, which had previously been dried for 6 h at 400° C., were immersed into a saturated CuSO4 solution for 2 h and thus soaked therewith. The bluish product was then separated, flushed with 200 ml of deionized water, and dried for 12 h at 60° C. and thereafter for 6 h at 350° C. A CuSO4 content of 39.7 wt % was determined using XRF analysis.

synthesis example 2

[0032]In a manner analogous to Synthesis Example 1, zeolite Y was soaked with a saturated CuCl2 solution. A CuCl2 content of 44.3 wt % was determined using XRF analysis.

synthesis example 3

[0033]In a manner analogous to Synthesis Example 1, zeolite Y was soaked with a saturated CdCl2 solution. A CdCl2 content of 59.5 wt % was determined using XRF analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com