Grid Plate for Laying Tile on Uneven Surfaces

a grid plate and tile technology, applied in the field of grid plates for laying tiles, can solve the problems of inability to disclose a grid plate for laying mosaic tiles, excessive or lack of thinset, etc., and achieve the effect of facilitating the distribution of thinset and facilitating flush and level laying of tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

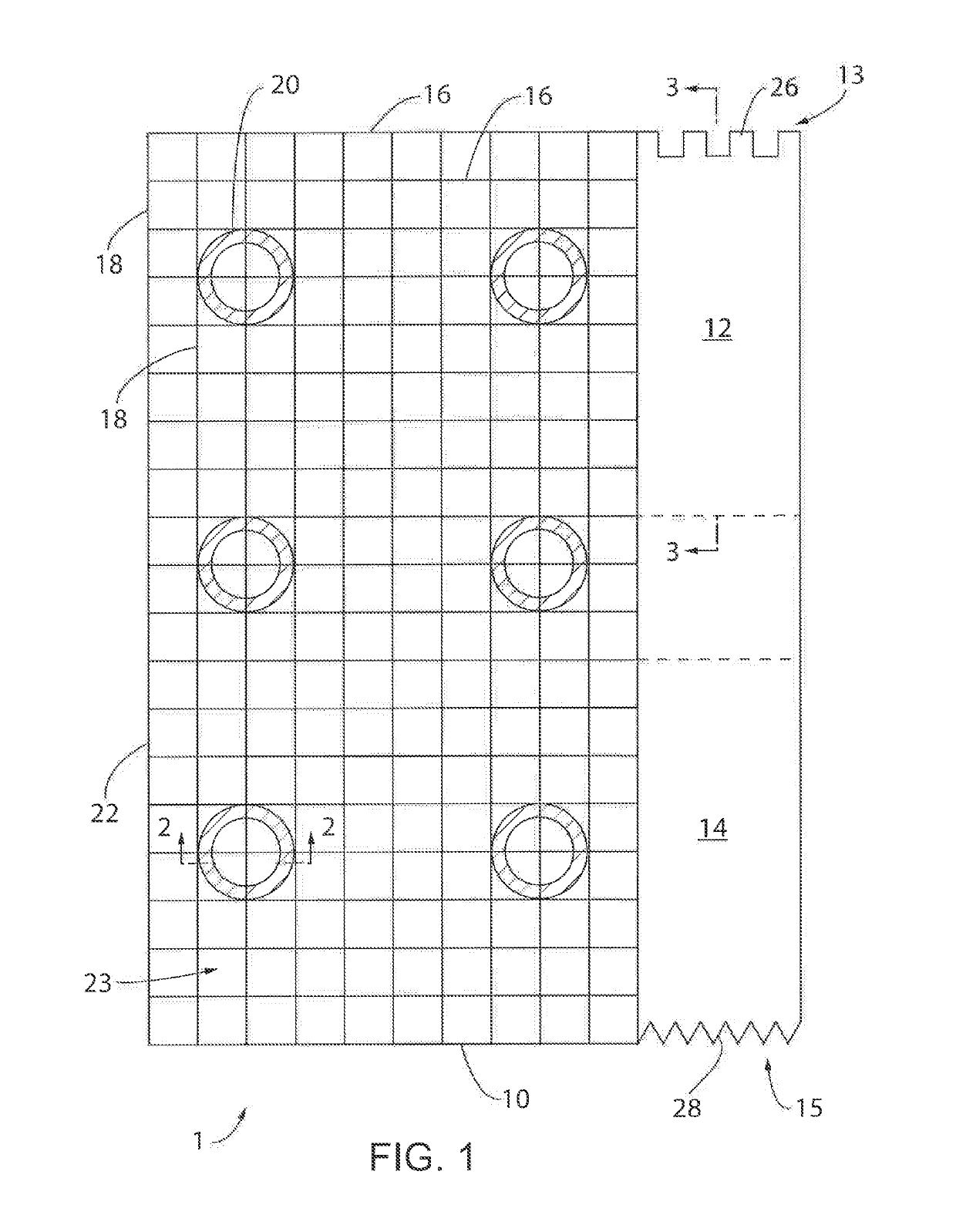

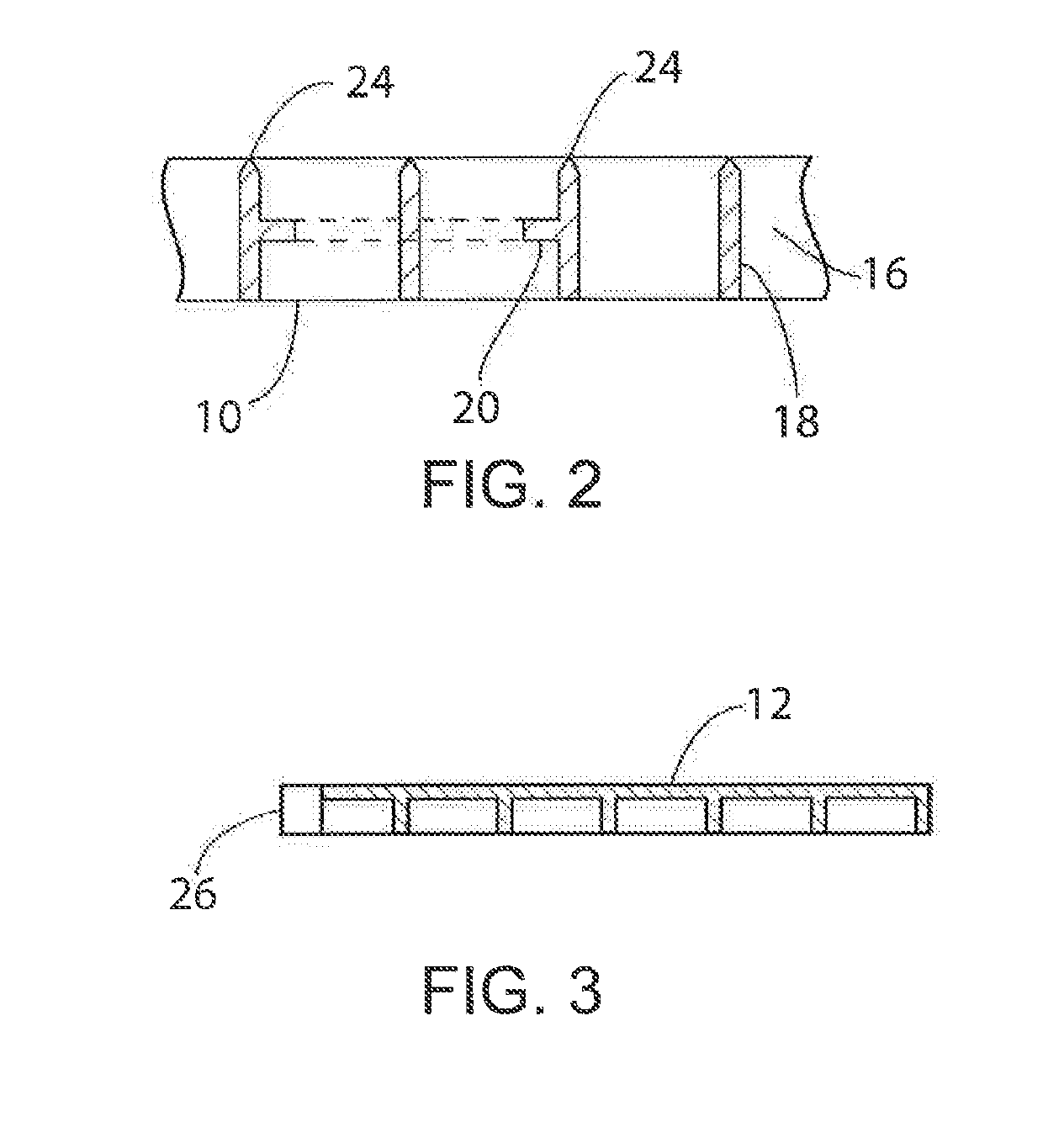

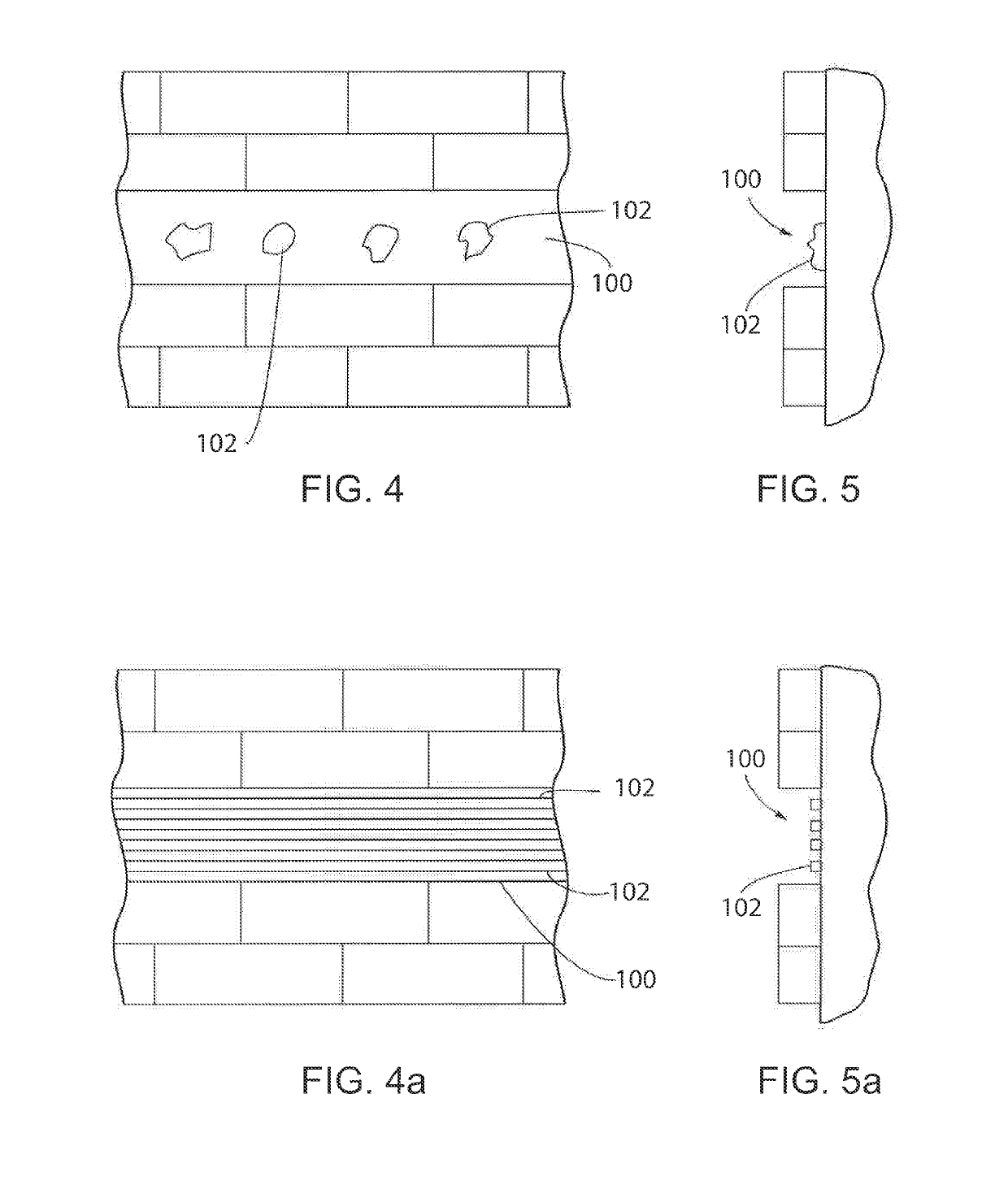

[0043]With reference now to the drawings, and particularly to FIG. 1, there is shown a top view of a grid plate assembly 1. The grid plate assembly 1 preferably includes a grid plate member 10, a detachable large groove tile trowel 12, and a detachable small groove tile trowel 14. It is understood that the grid plate 1 may be sold as a kit allowing the user to complete the leveling tile task with the assistance of detachable tools also included in the kit.

[0044]While the grid plate assembly 1 includes multiple attached and detachable elements, it is understood that the grid plate assembly 1 may only include the grid plate member 10 without the detachable tile trowels 12, 14 or other attachments. In alternative embodiments, the grid plate assembly 1 may include other or additional tiling tools, such as multi-sized tile trowels and depth measurement tools, as further described below.

[0045]In one embodiment the grid plate member 10 may be a rectangular sheet of material, in one embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com