Weighted Exercise Sliding Device

a weighted exercise and sliding technology, applied in the field of exercise and fitness devices, can solve the problems of no means to control the difficulty and intensity of the exercise being performed, devices providing no means of transportation and use, etc., to reduce the inventory of materials, reduce manufacturing costs, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

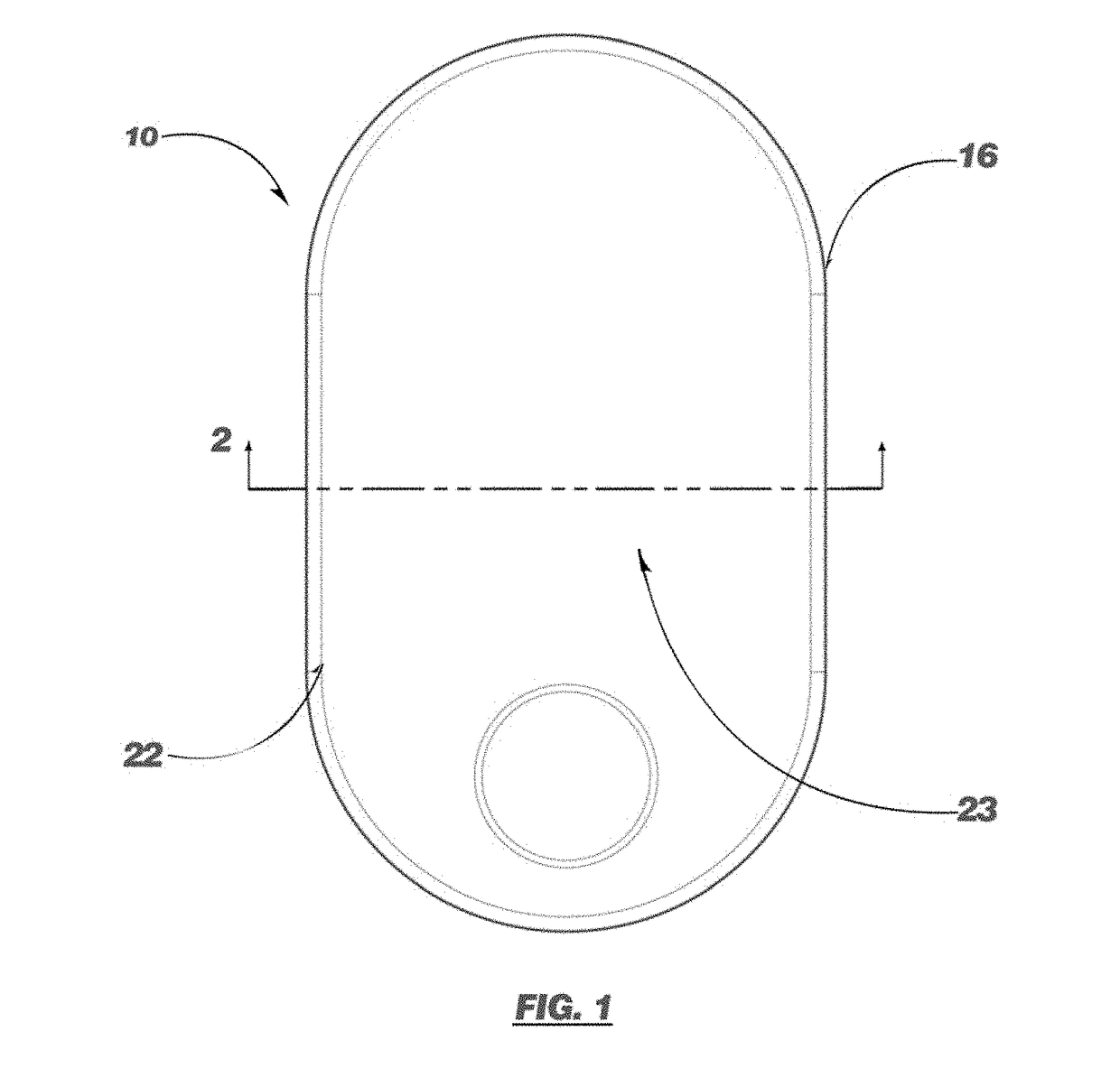

[0022]The weighted exercise slide device 10 is shown in the drawings particularly FIGS. 1 and 2. The weighted exercise device 10 is comprised of a weight plate 12 having a desired size and weight. The weight plate 12 is encapsulated within a layer of thermoplastic polymer material 16, such as high density polyethylene (HDPE) or another suitable polymer material. The layer of thermoplastic material 16 surrounding the weight plate 12 creates a smooth low friction bottom sliding surface 24 for the device 10. A friction enhanced gripping surface 23 is provided on the top surface 22 of the device 10 to aid a user in holding or gripping the weighted exercise slide device.

[0023]The friction enhanced surface 23 may be provided by stippling, a plurality of surface grooves, an abrading, or checkering on the top surface 22. However, it is thought that a layer of soft friction enhanced material 14 attached by glue or other suitable bonding means to top surface 22 of the device 10 will be utiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com