Semiconductor package device and method of manufacturing the same

a technology of semiconductor and package device, which is applied in the direction of semiconductor device, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problem of taking a great cost to use the tsv interposer to provide electrical interconnection between the two dies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

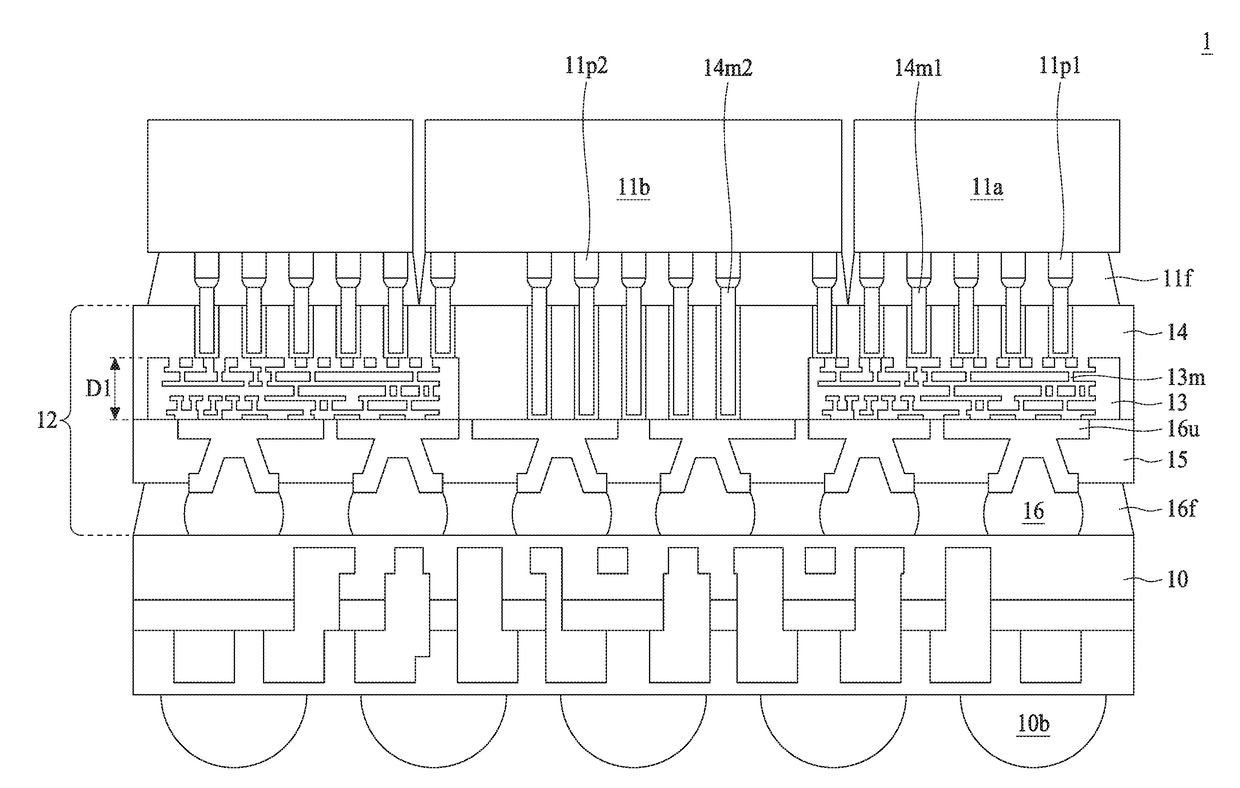

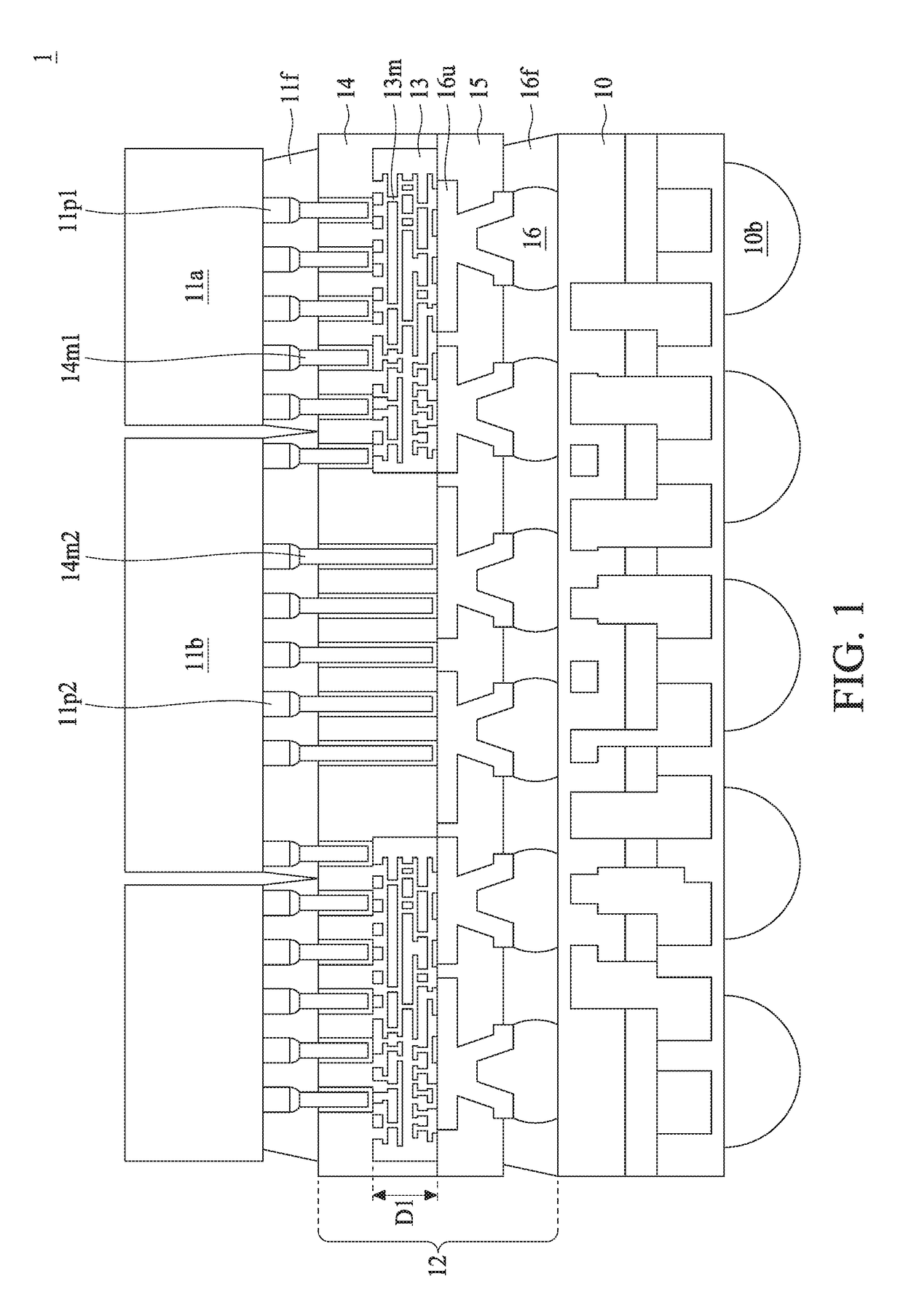

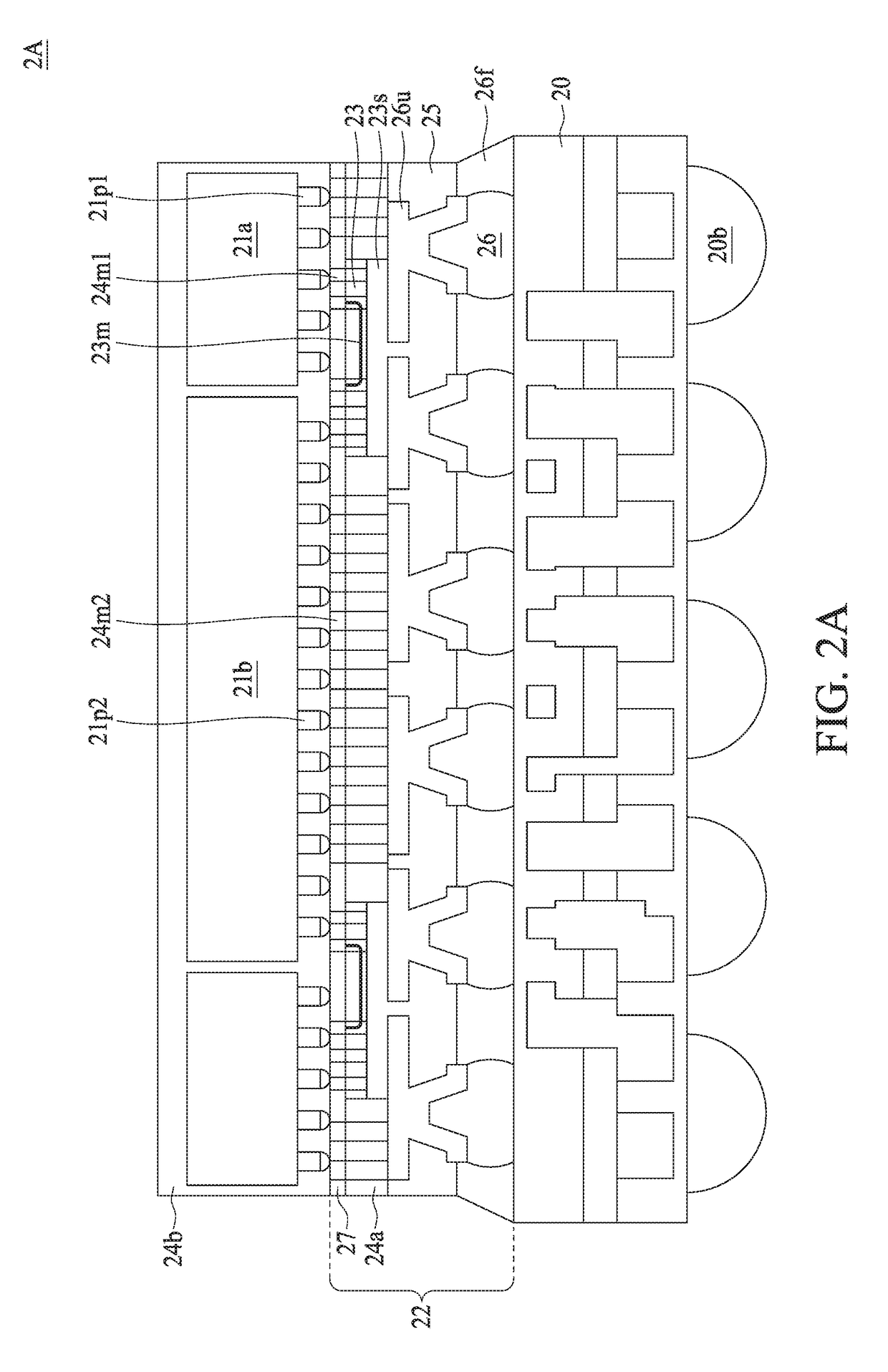

[0012]FIG. 1 illustrates a cross-sectional view of a semiconductor package device 1 in accordance with some embodiments of the present disclosure. The semiconductor package device 1 includes a substrate 10, electronic components 11a, 11b and an interconnection component 12.

[0013]The substrate 10 may be a flexible substrate or a rigid substrate, depending upon the specific application. In some embodiments, the substrate 10 includes a plurality of electrical traces disposed therein. In some embodiments, an external contact layer is also formed or disposed on the substrate 10. In some embodiments, the external contact layer includes a ball grid array (BGA). In other embodiments, the external contact layer includes an array such as, but not limited to, a land grid array (LGA) or an array of pins (PGA). In some embodiments, the external contact layer includes solder balls 10b, which are used and are composed of lead or are lead free (e.g., including such materials as alloys of gold and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com