In situ apparatus and method for providing deuterium oxide or tritium oxide in an industrial apparatus or method

a tritium oxide and industrial apparatus technology, applied in the direction of hydrogen isotopes, separation processes, heavy water, etc., can solve the problems of high cost, difficult to obtain, and generally hindered use, so as to prevent loss and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

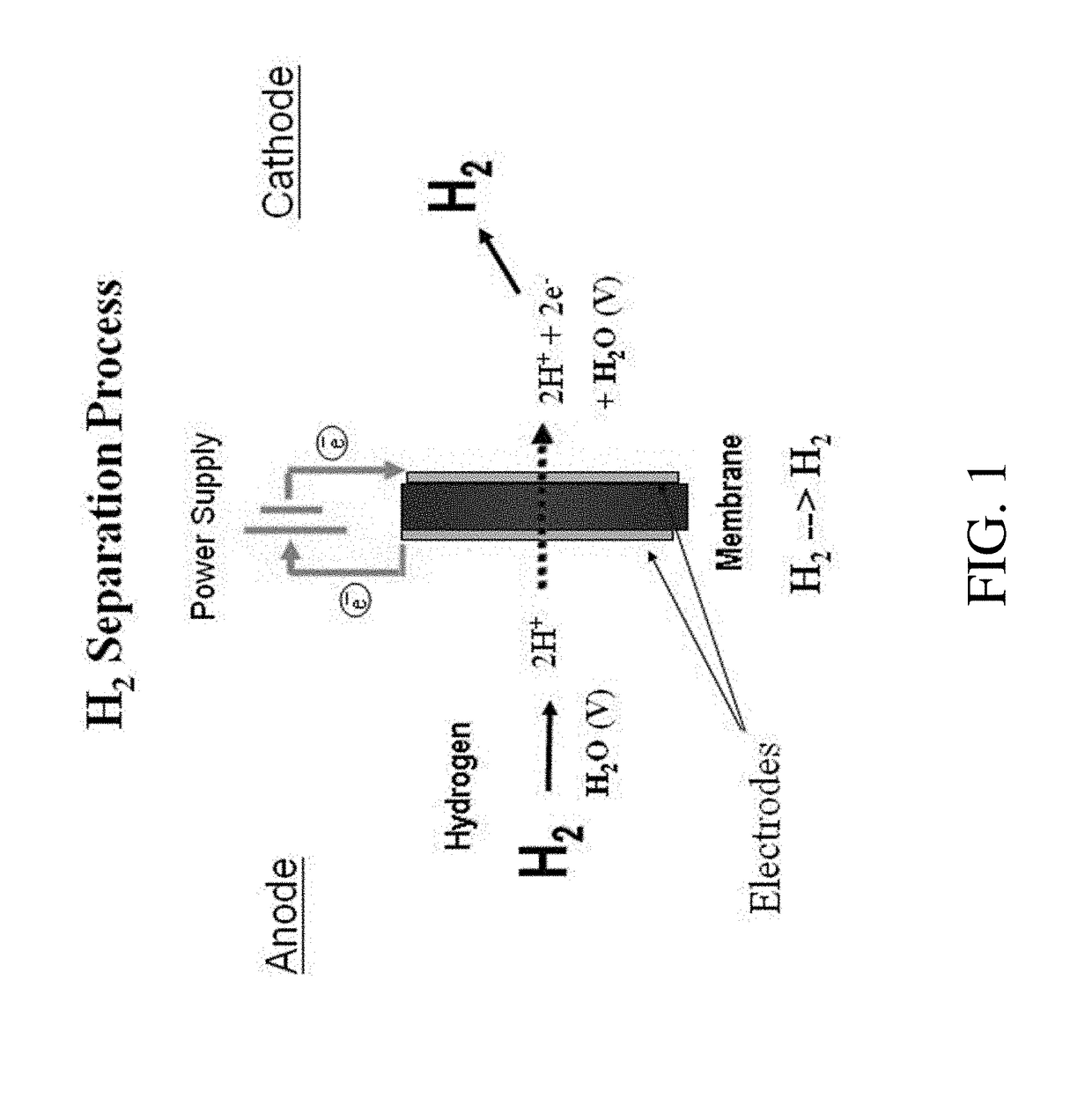

[0063]Tests were performed to investigate isotopic exchange within an electrochemical pump. The pump and humidifier were pre-treated with D2O and used to pump D2. High isotopic purity was observed in gas exiting or being output from the electrochemical pump. Upon switching from using a D2O pretreated humidifier to a H2O humidifier a rapid increase in H was observed in gas exiting the pump. This demonstrated how readily isotopes are exchanged within the electrochemical device and supporting sub-systems.

[0064]Use of the appropriate isotopic form of water is required in order to maintain high isotopic purity of products evolving from electrochemical devices.

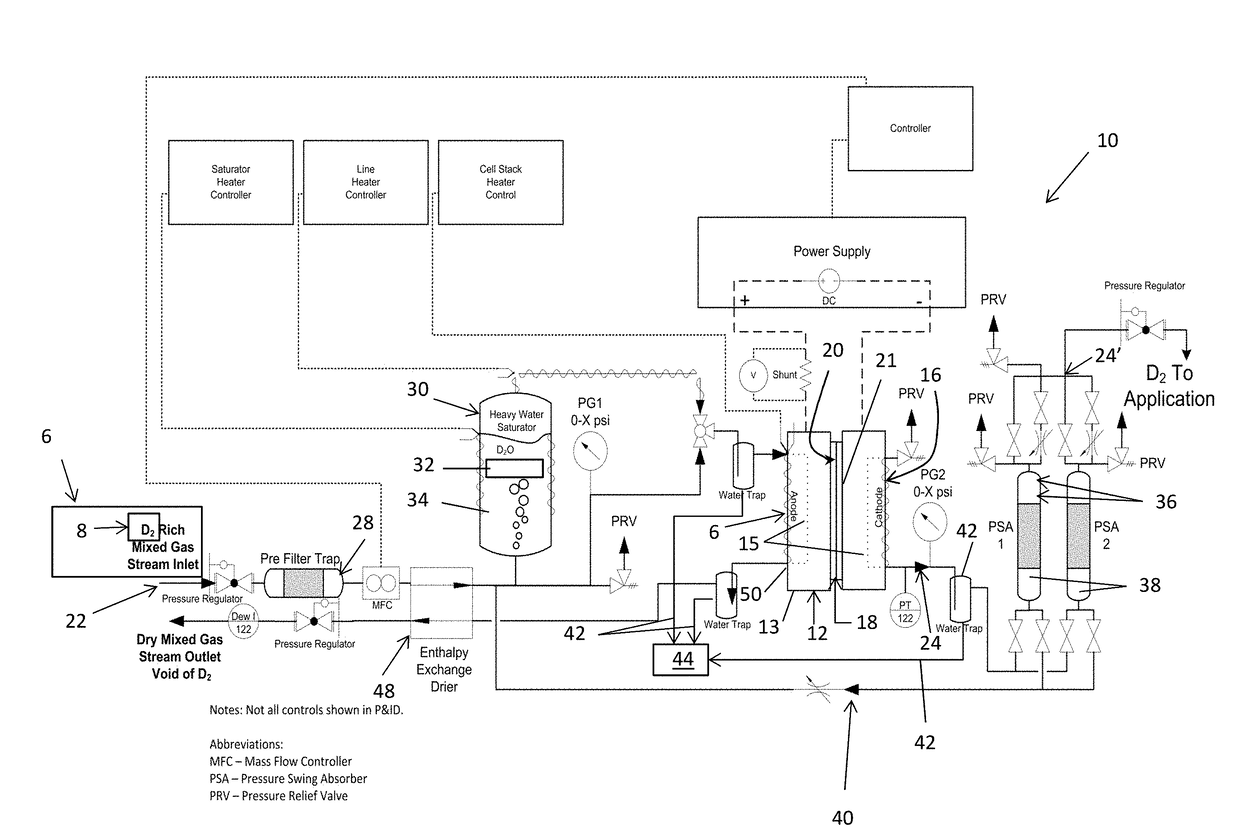

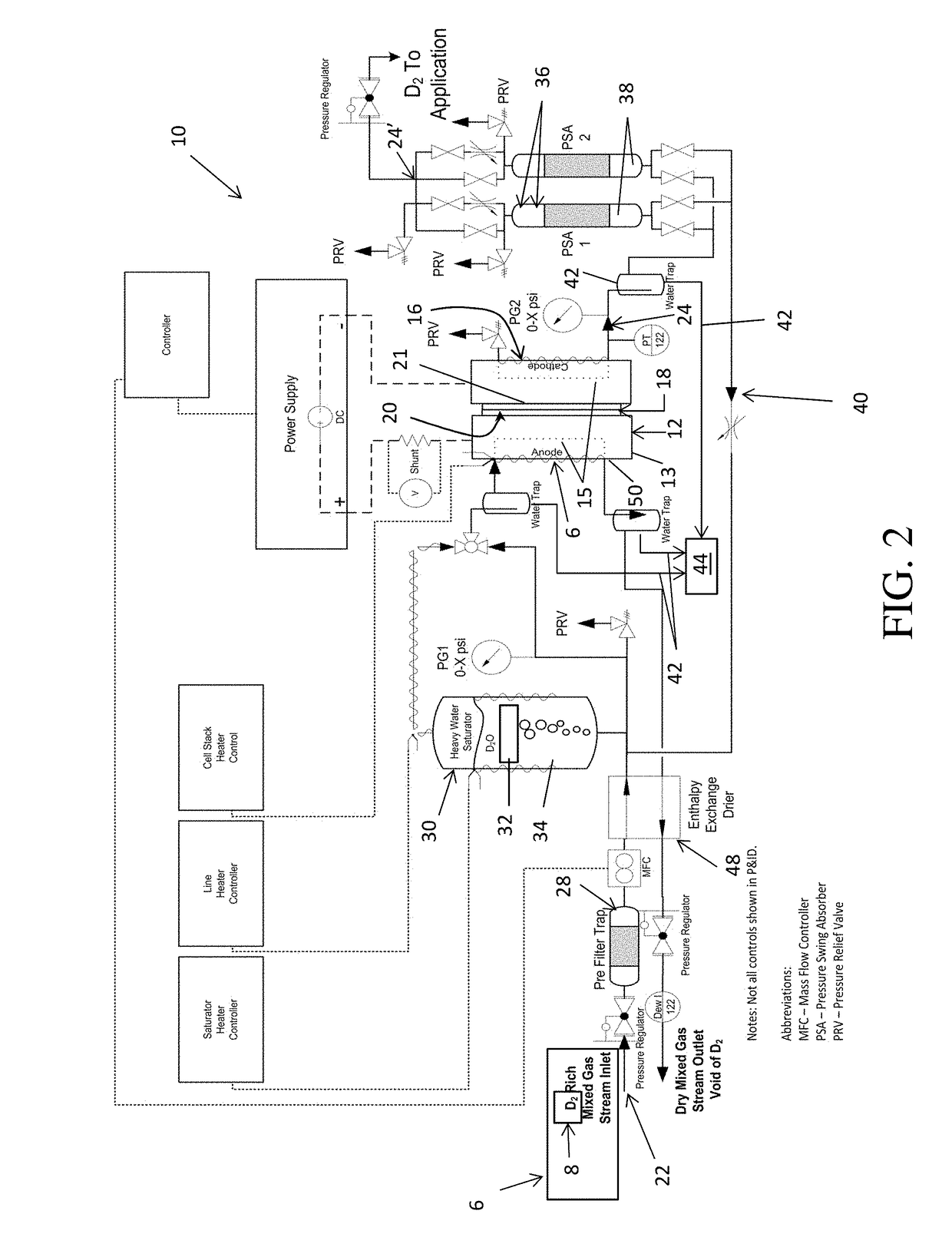

[0065]Referring now to FIG. 2, an embodiment of a hydrogen isotope recycling apparatus 10 for recycling or reclaiming an isotope of hydrogen 8 (e.g. D or T) is disclosed. The apparatus is configured to receive a gas stream 6 that is rich in a diatomic molecule of an isotope of hydrogen (e.g. D2 or T2, or possibly also D2O or T2O). I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com