Golf ball

a golf ball and ball technology, applied in the field of golf balls, can solve the problems of cracks in the core and core breakage, and achieve the effects of improving durability, prolonging flight distance, and poor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

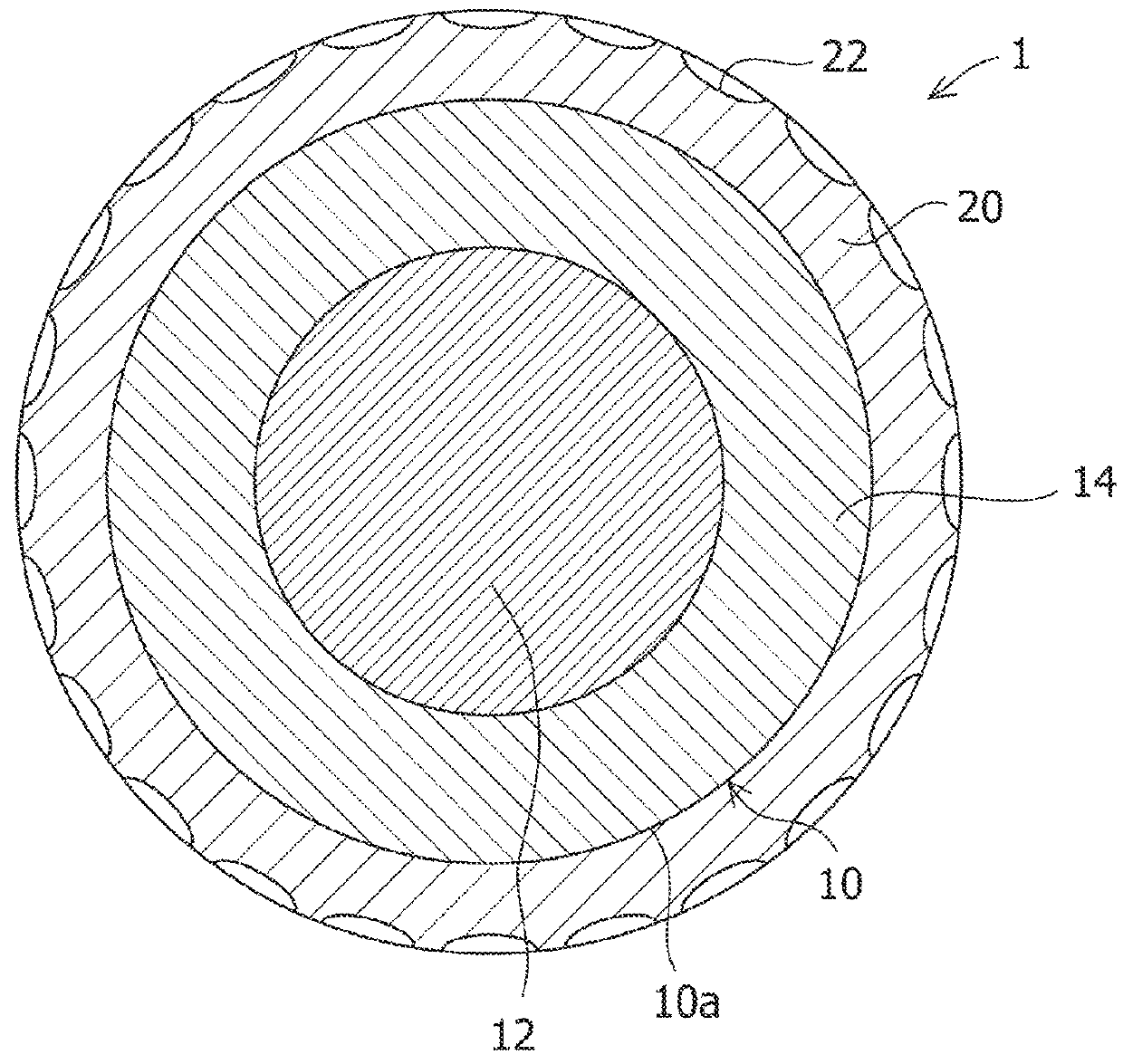

Image

Examples

example

[0047]Golf balls comprising a core having a composition (parts by weight as a unit) and configuration shown in Table 1 were manufactured, and then tests were carried out about various aspects of performance of the core and golf ball, especially, the productivity of the core, the spin performance of the golf ball, and the durability of the golf ball. The results are shown in Table 2.

[0048]All the golf balls in Examples and Comparative Examples contained the same materials having the same composition mainly comprising ionomer resin and had dimples arranged in the same manner.

TABLE 1ExamplesComparative examples123451234CenterButadiene rubber100100100100100100100100100coreZinc oxide444444444Barium sulfate19.919.919.99.1213.1519.919.919.913.15Age resister0.10.10.10.10.10.10.10.10.1Pentachlorothiophenol zinc salt0.10.10.10.20.10.10.10.10.1Unsaturated metal carboxylate A———35.728.1————Unsaturated metal carboxylate B151515——15151528.1Metal carboxylate A2.22.22.26.3—2.22.22.2—Metal carboxyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com