Air-liquid heat exchanger

a technology of air-liquid heat exchanger and heat exchange system, which is applied in the direction of heat transfer optimization, solar heat collectors with working fluids, stationary tubular conduit assemblies, etc., can solve the problems of air inability and no one has taken seriously the task of developing a more efficient air-liquid heat exchanger, so as to improve the control of certain phenomena and increase the turbulence in the air stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

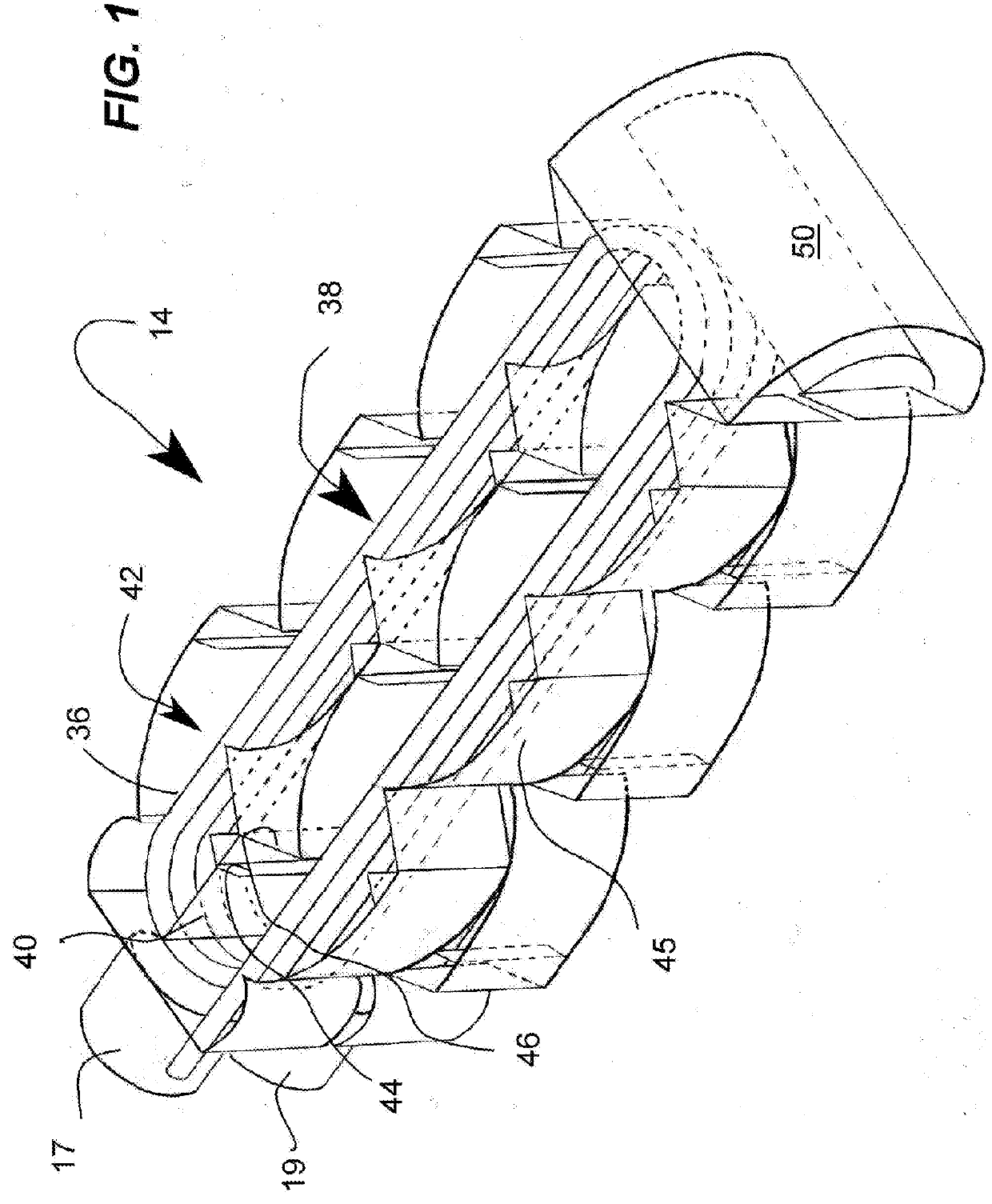

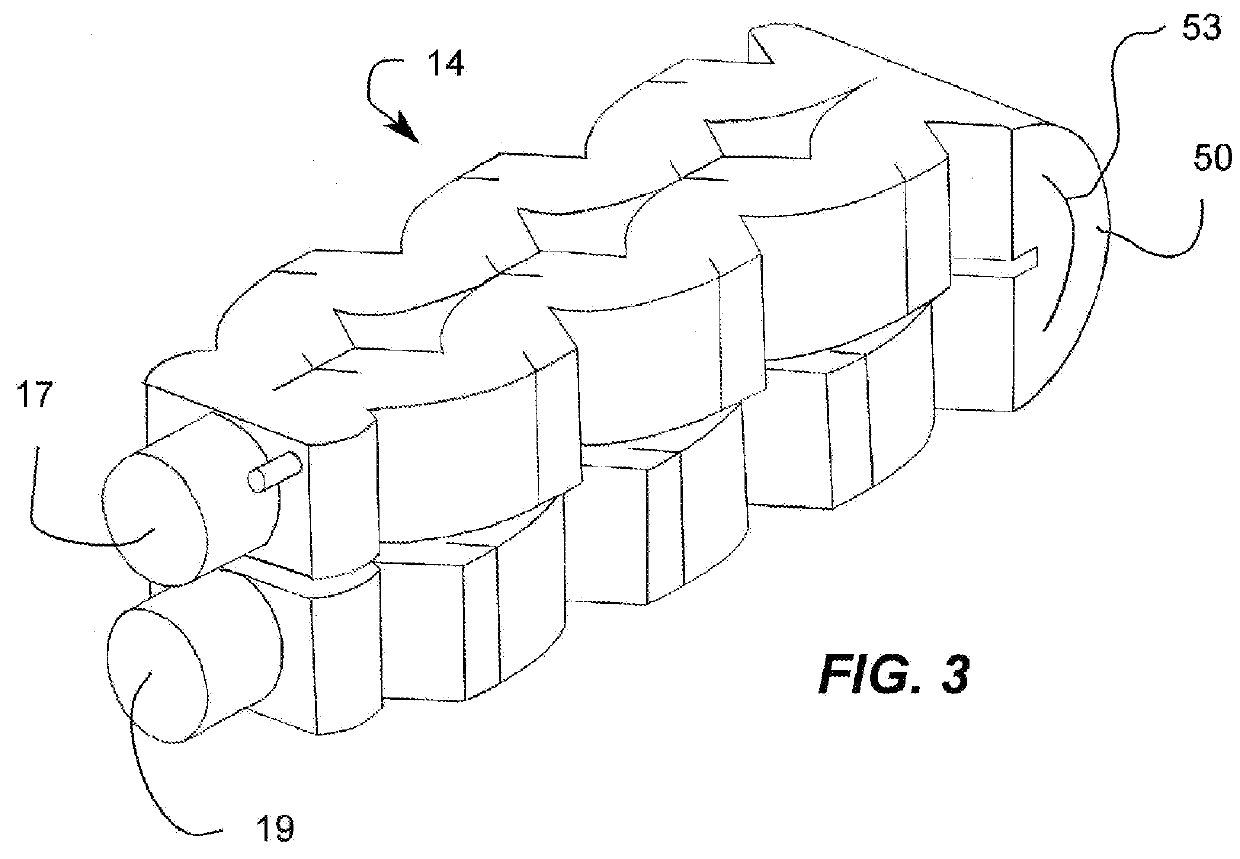

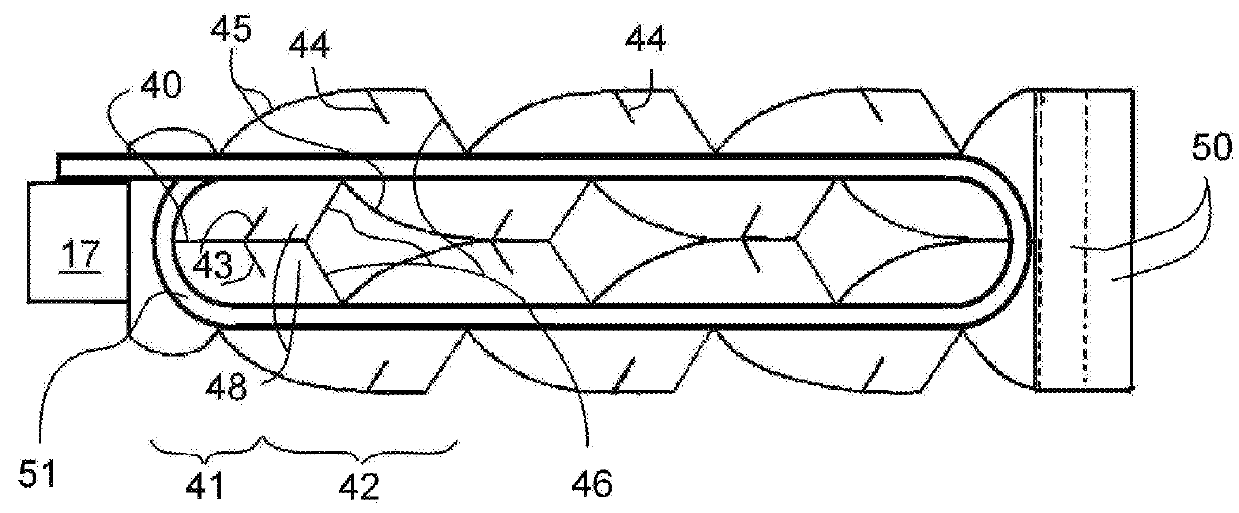

[0048]A heat exchange system for use in liquid-gas heat exchange using solar energy is comprised of three (components: A solar heater panel (10), a double pipe (28), and a heat exchanger (14). Other components include a water pump (13) and a water tank (17).

[0049]Except for the fact that it uses air instead of water, the solar air-heater panel (10), is similar to solar liquid-heater panels. Sunlight passes through a sheet of transparent glass (16) and heats up a back panel (18) painted a dark color so as to generate as much heat as possible. There is a single circuitous path (20) defined by wall members (22) that snakes across the panel (10). The air is forced, by way of a fan (24), pushing air into an entry (23), passing over a plurality of baffles (26) which mixes the air so that it is evenly warmed up with minimal temperature variations, and coming out at an exit point (25). The air-heater panel (10) does not form part of this invention, it is just introduced here to show the gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com