High Definition Stencils With Easy to Clean Properties for Screen Printing

a stencil and high-definition technology, applied in the field of high-definition stencil systems, can solve the problems of difficult to meet using existing technology, and achieve the effect of easy soldering or metallic, and resistance to stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

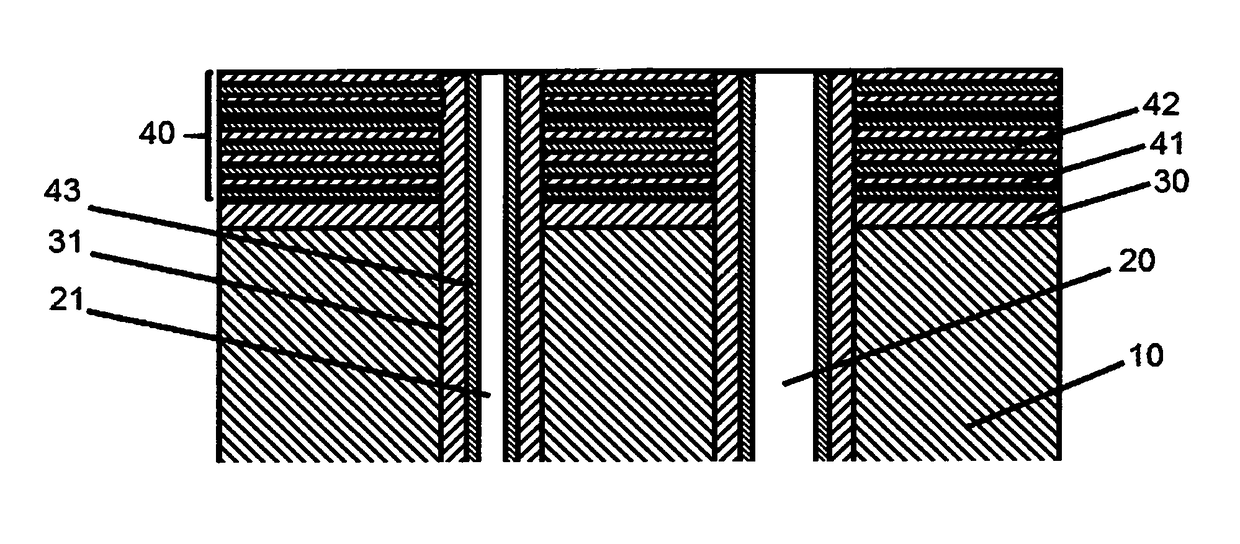

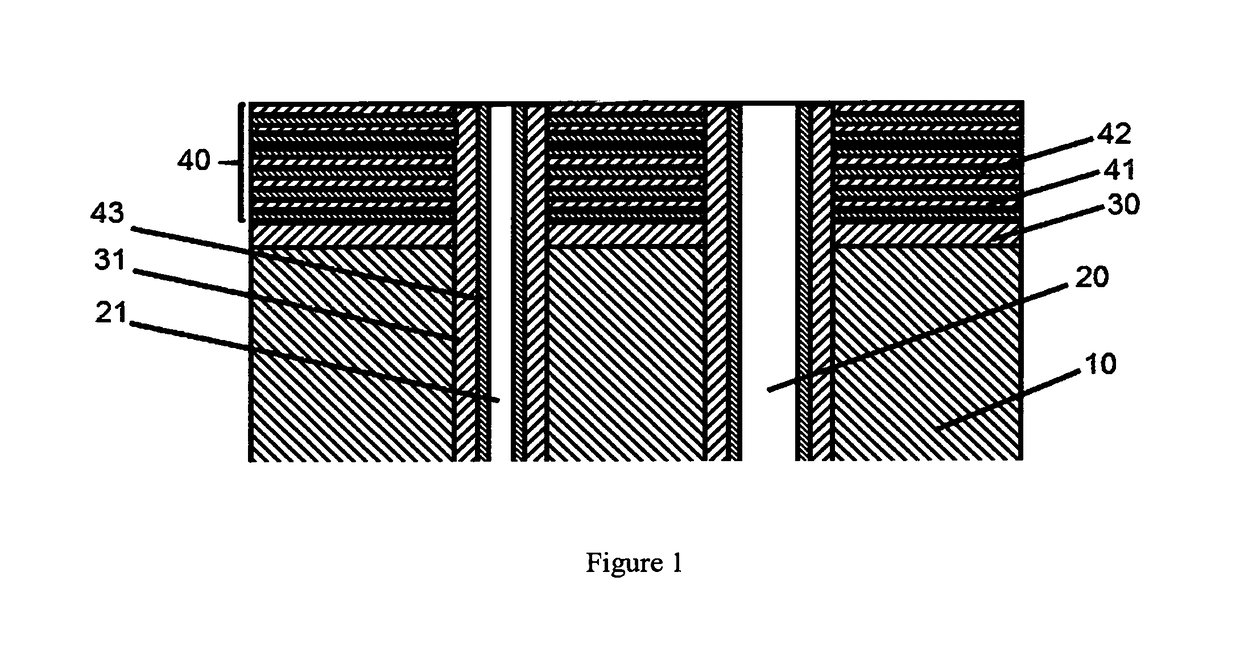

[0010]As shown in FIG. 1, the structure of the stencil is described in two embodiments as follows. In the first embodiment, the substrate stencil (10) is made of hard nickel by electroforming using a dedicated nickel-sulfamate solution. For two-dimensional stencils, the stainless steel mandrel is flat and polished to a grit 500 finish which has an average surface roughness (Ra) between 0.1 and 0.25 μm, preferably Ra is under 0.2 μm. For three-dimensional stencils, the stainless steel mandrels are polished to the same finish and then machined with pockets to enclosure the protruded chips on a PCB in designated areas. The mandrels are submerged in 25% wt to 36% wt nitric acid solution to remove residual metal debris, and then degreased by immersion in an alkaline degreaser. Subsequently, a nickel strike layer is plated on a mandrel in Woods nickel strike solution. This nickel strike solution has 220 g / l nickel chloride hexahydrate (NiCl2.6H2O) and 110 ml / l hydrochloric acid (HCl). Pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com