Water borne coating compositons and polymers therefor

a water-borne paint composition and composition technology, applied in the field of stable water-borne coating compositions and polymers, can solve the problems of less desired paint compositions, less stable compositions, and high price of titanium dioxide in water-borne paint compositions,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

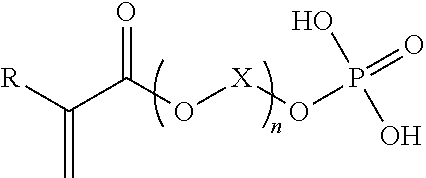

Image

Examples

example 1

[0061]This Example prepares Polymer A (1.5% phosphate surfactant, 15% branched vinyl ester hydrophobic monomer) and formulated into a paint that remains stable on heat aging at 140° F. for four weeks. Polymer A had a phosphate to hydrophobic relationship of 1:10.

[0062]Polymer A is prepared as follows: Prepare the monomer pre-emulsion by mixing 638.50 grams of water, 0.8 grams sodium bicarbonate, 39.61 grams (60% active) anionic surfactant, 47.54 grams (50% active) nonionic surfactant, 53.41 grams of phosphate surfactant (55.6% active, Sipomer monomer, Solvay S.A.), 205.99 grams butyl acrylate, 1465.67 grams vinyl acetate, 1.99 grams acrylic acid, 9.9 grams allyl imidazolidinone, 24.5 grams allyloxy hydroxypropyl sodium sulfonate, and 297 grams branched vinyl ester (vinyl neodecanoate, veova monomer, Momentive Specialty Chemicals, Inc.).

[0063]Charge the reactor fitted with a paddle stirrer, a thermocouple, nitrogen inlet and reflux condenser with 877 grams water, 1 gram sodium bicarb...

example 2

[0064]This Example prepares comparative Polymer B (1.5% phosphate, 0% branched vinyl ester hydrophobic monomer) and when formulated into a paint, it gelled in one week on heat aging at 140° F. Comparative Polymer B had a phosphate to hydrophobic relationship of 0.

[0065]Polymer B is prepared as follows: Prepare the monomer pre-emulsion by mixing 642.23 grams of water, 0.8 grams sodium bicarbonate, 33.14 grams (60% active) anionic surfactant, 47.71 grams (50% active) nonionic surfactant, 53.61 grams of the phosphate surfactant (55.6% active) of Example 1, 423.47 grams butyl acrylate, 1552.72 grams vinyl acetate, 1.99 grams acrylic acid, 9.9 grams allyl imidazolidinone, and 24.5 grams allyloxy hydroxypropyl sodium sulfonate.

[0066]Charge the reactor fitted with a paddle stirrer, a thermocouple, nitrogen inlet and reflux condenser with 878.7 grams water, 1 gram sodium bicarbonate, 33.14 grams (60% active) anionic surfactant. The contents of the flask are heated to 70° C. under nitrogen a...

example 3

[0067]This Example prepares Polymer C (1.2% phosphate, 10% branched vinyl ester hydrophobic monomer) and formulated into a paint that remained stable on heat aging at 140′F. Polymer C had a phosphate to hydrophobic relationship of 1:8.3.

[0068]Polymer C is prepared as follows: Prepare the monomer pre-emulsion by mixing 733.15 grams of water, 0.8 grams sodium bicarbonate, 48 grams phosphate surfactant (55.6% active) of Example 1, 37.6 grams (60% active) anionic surfactant, 45 grams (50% active) nonionic surfactant, 369 grams butyl acrylate, 1644.6 grams vinyl acetate, 2.25 grams acrylic acid, 15.8 grams allyl imidazolidinone, 22.5 grams allyloxy hydroxypropyl sodium sulfonate, and 225 grams branched vinyl ester (vinyl neodecanoate) of Example 1.

[0069]Charge the reactor fitted with a paddle stirrer, a thermocouple, nitrogen inlet and reflux condenser with 937.4 grams water, 1.1 gram sodium bicarbonate, 15 grams (60% active) anionic surfactant, 45 grams (50% active) nonionic surfactant....

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com