Vertically stacked floors

a vertical and stacked technology, applied in the direction of dwelling buildings, construction, building construction, etc., can solve the problems of difficulty in including, within the building customized units, individual rooms with higher cathedral or loft ceilings, etc., and achieve the effect of increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

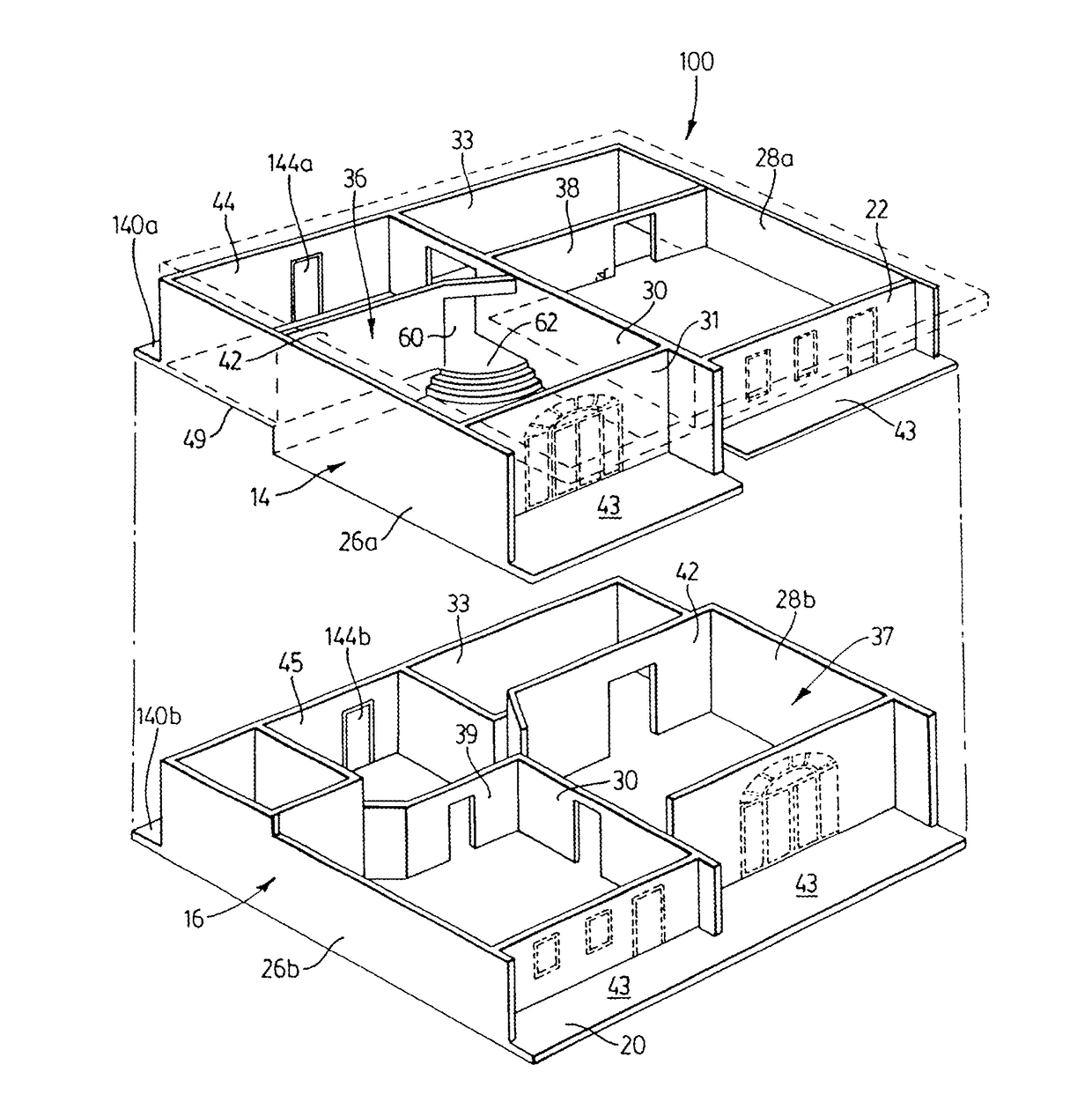

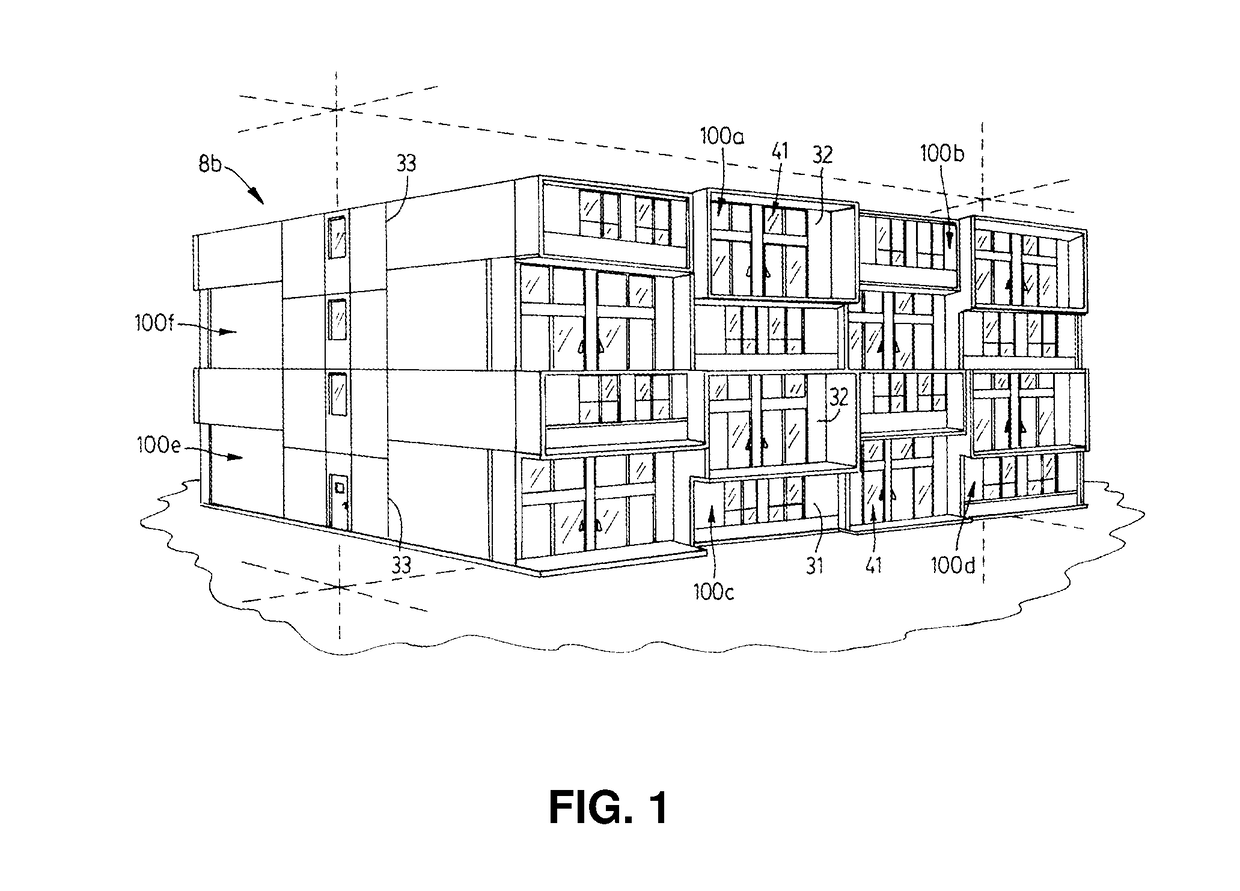

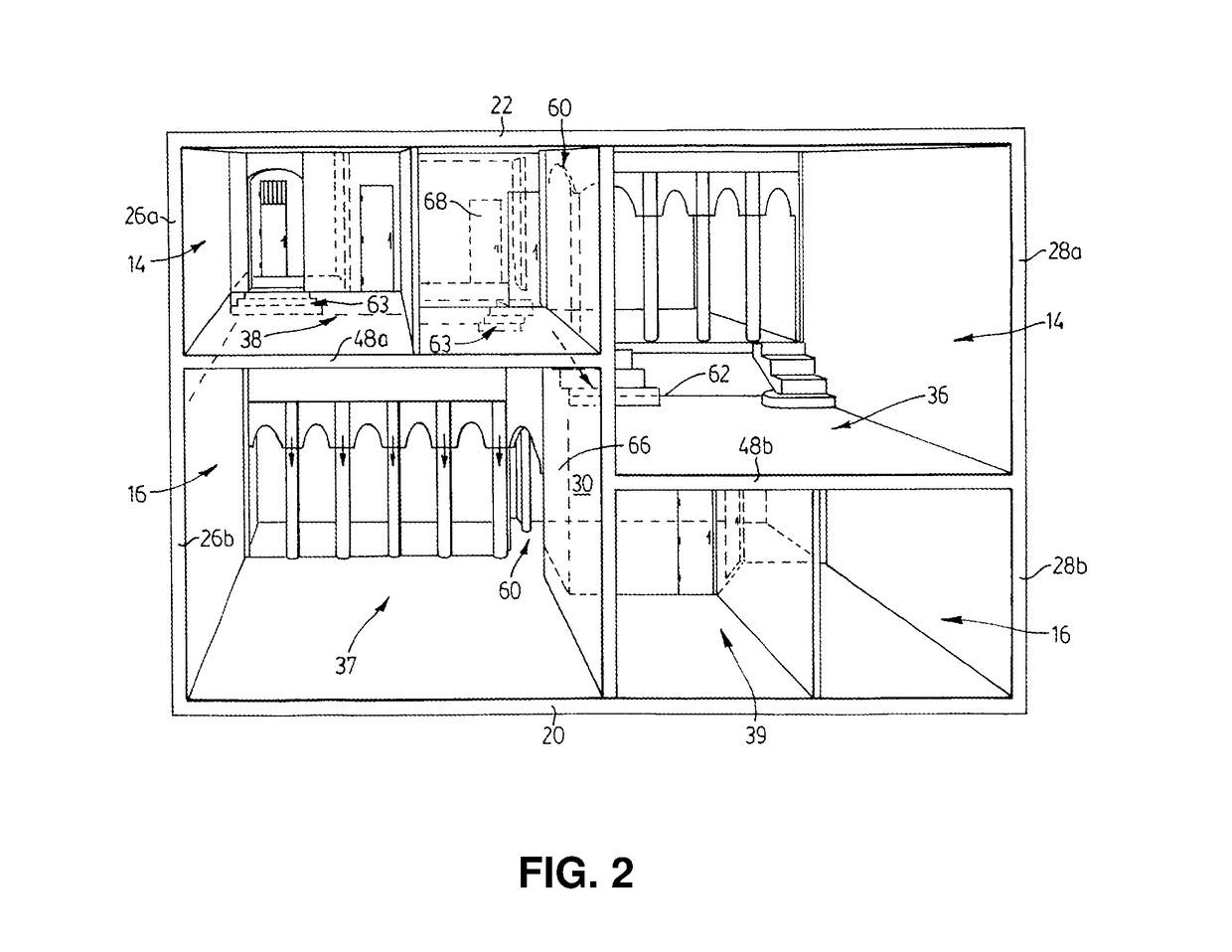

[0039]Reference may be made to FIGS. 1 to 7, which show a building 8B incorporating a number of building construction modules 100a-f in accordance with the invention, and wherein like reference numerals are used to identify like components. The modules 100a-f are of an identical or mirror construction and consist of upper and lower units 14, 16.

[0040]The module 100 of FIG. 1 has an overall height of approximately 2.5 conventional storeys with the forwardmost secondary living area 38, of the unit 14 consisting of a single one-storey unit positioned vertically directly above the primary living area 37 of the second other unit 16. The forwardmost secondary living area 39 of the lower unit 16 is positioned directly below the primary living area 36 of the upper unit 14. This configuration advantageously provides the primary living area 36, 37 of each unit 14, 16 with a cathedral height ceiling of 1.5 storeys.

[0041]FIG. 5 shows the concrete slab 49 placed approximately or exactly midway b...

first embodiment

[0045]By way of non-limiting example, reference may be had to FIG. 9 which illustrates schematically one possible alternate high-rise building 8 in which like reference numerals are used to identify like components. The building 8 of FIG. 9 is shown as incorporating a number of the building modules 10 in accordance with the invention, shown by reference numeral 120 as occupying the uppermost six storeys of the building 8, a number of modules 100, shown by reference numeral 122 as occupying the middle five storeys of the building 8, and a lowermost zone 124 of single conventional one storey residential units 126.

[0046]Although the detailed description describes the present construction modules as being used in concrete based structures, any brick or wood structure having a design appropriate for different modules may be used in a townhome or detached home construction. By way of non-limiting example, FIG. 10 shows one such townhome construction in which like reference numerals are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com