Grease compositions

a composition and metal technology, applied in the field of grease compositions, can solve the problems of increasing the cost of additional treatments, and requiring additional treatments, so as to achieve low cost, easy manufacturing, and attractive low friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

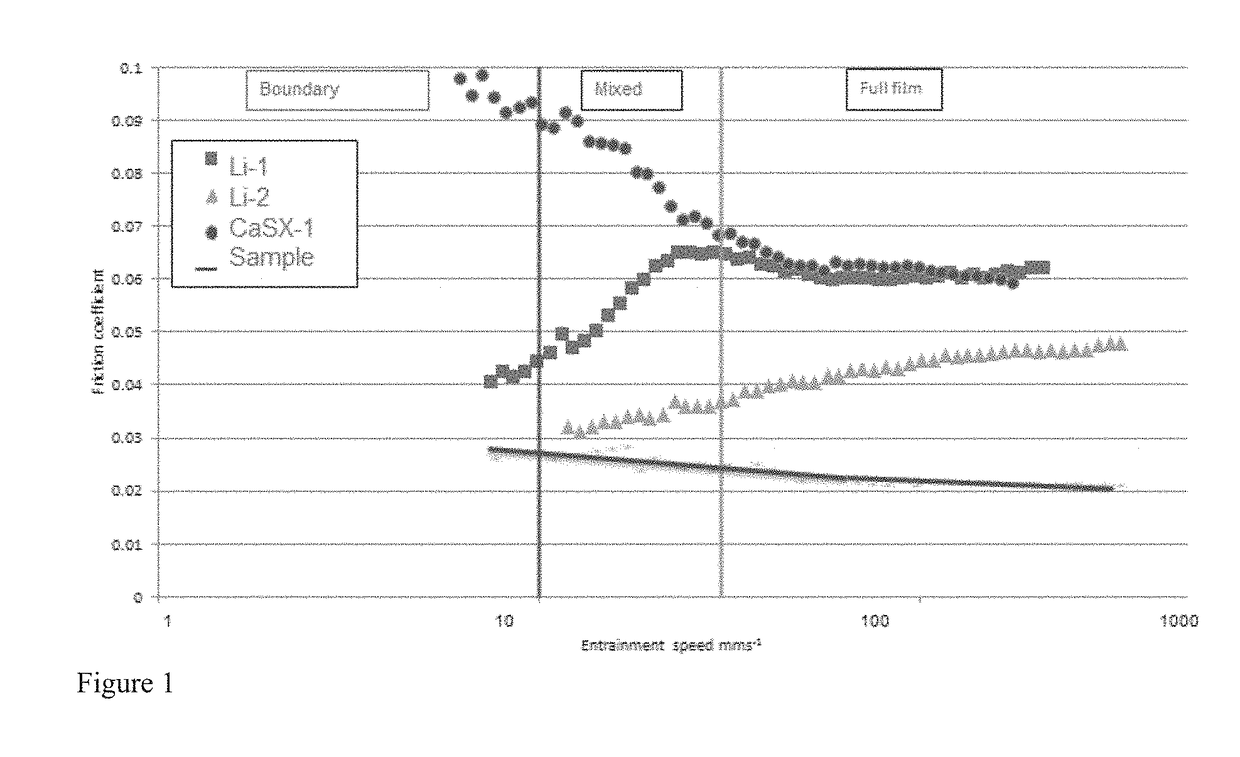

[0098]The performance of four grease compositions has been tested on tribological and friction performance on the Ball-on-disc, the Mini Traction Machine, at Imperial College, London UK. In each case the test procedure consists of four steps, i.e. first a grease working step which is followed by three consecutive Stribeck step tests. Two grease samples from each of the four grease compositions have undergone the entire test procedure. These duplications were performed to monitor the repeatability of the test between two different tests carried out in the exact same conditions. The same ball and disc used for each of the grease samples were cleaned prior to running of the tests and the test repeat. The tests were run with fresh grease. The grease working step had the purpose of ensuring an even distribution of the grease and to prepare the same initial condition for each test, by shearing the grease in the same way and for the same time, before the start of the actual test. In Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| BET specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com