Composite constructed floating submersible water supply pump

a submerged pump and composite technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of galvanic corrosion of aluminum body pumps, and without use, the aluminum surface of coating technologies, such as hard-coat anodization and polyester powder coating, are stripped from the aluminum surface, etc., to achieve strong, durable and lightweight pump casings, the effect of sacrificing material strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

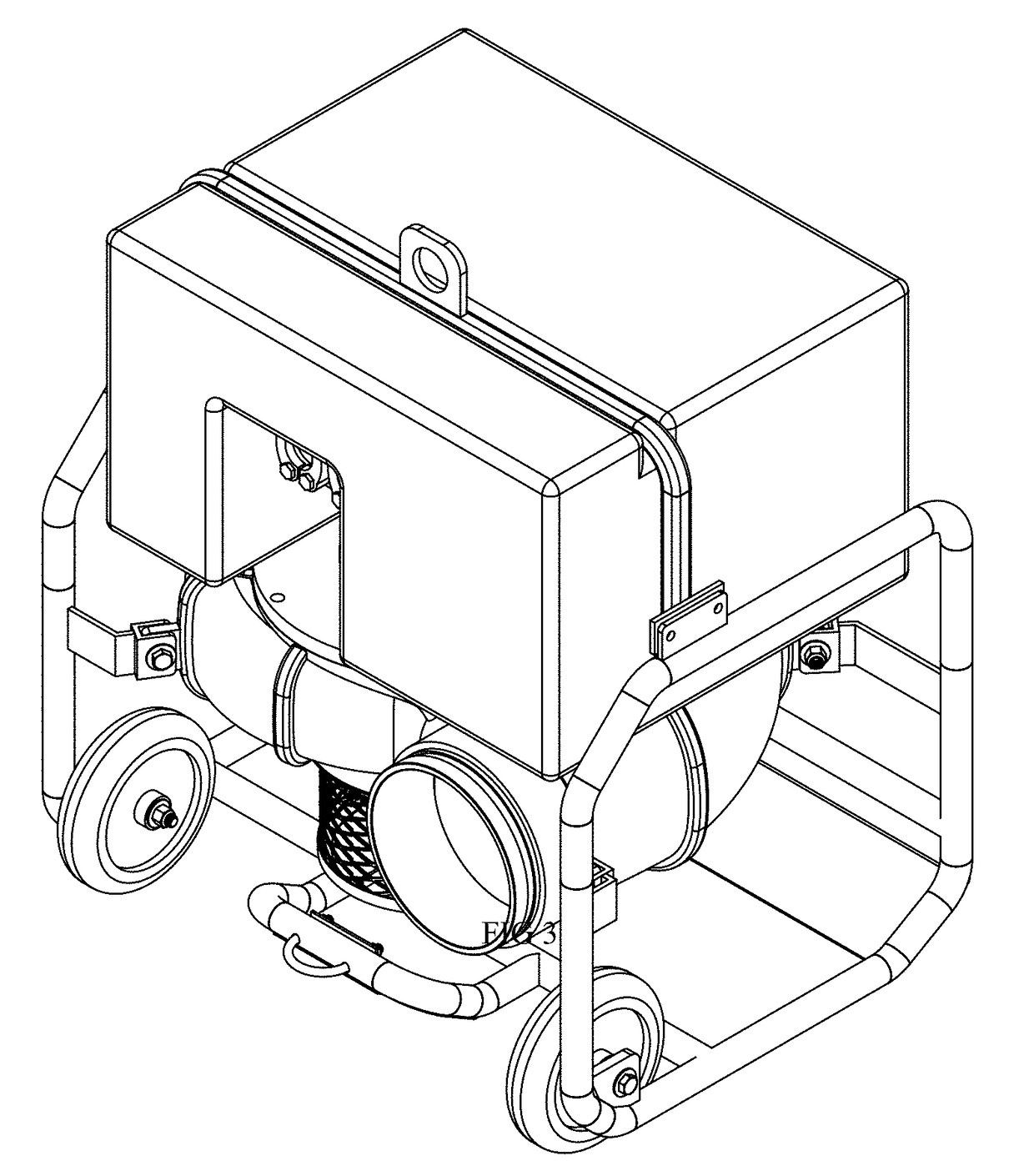

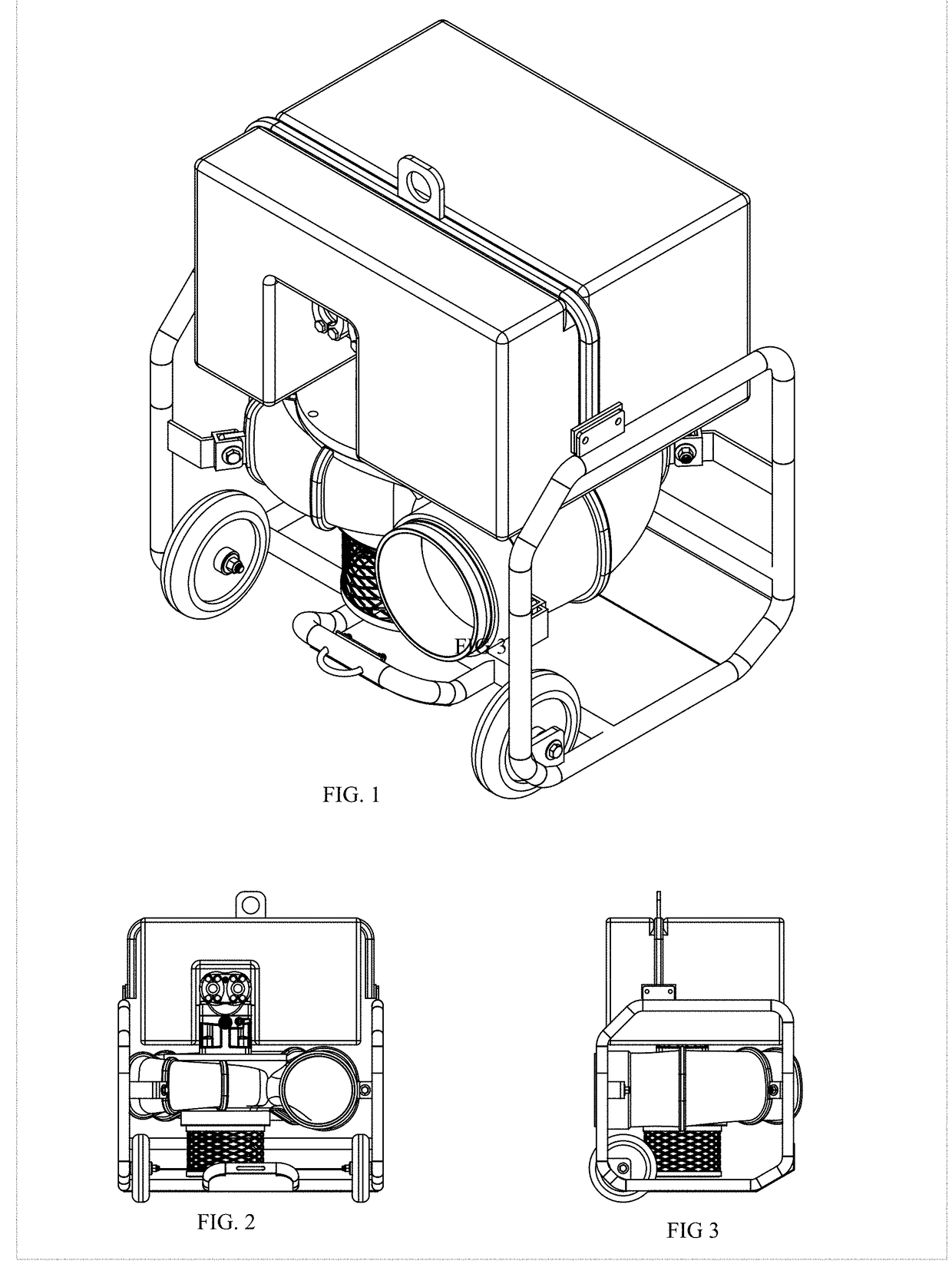

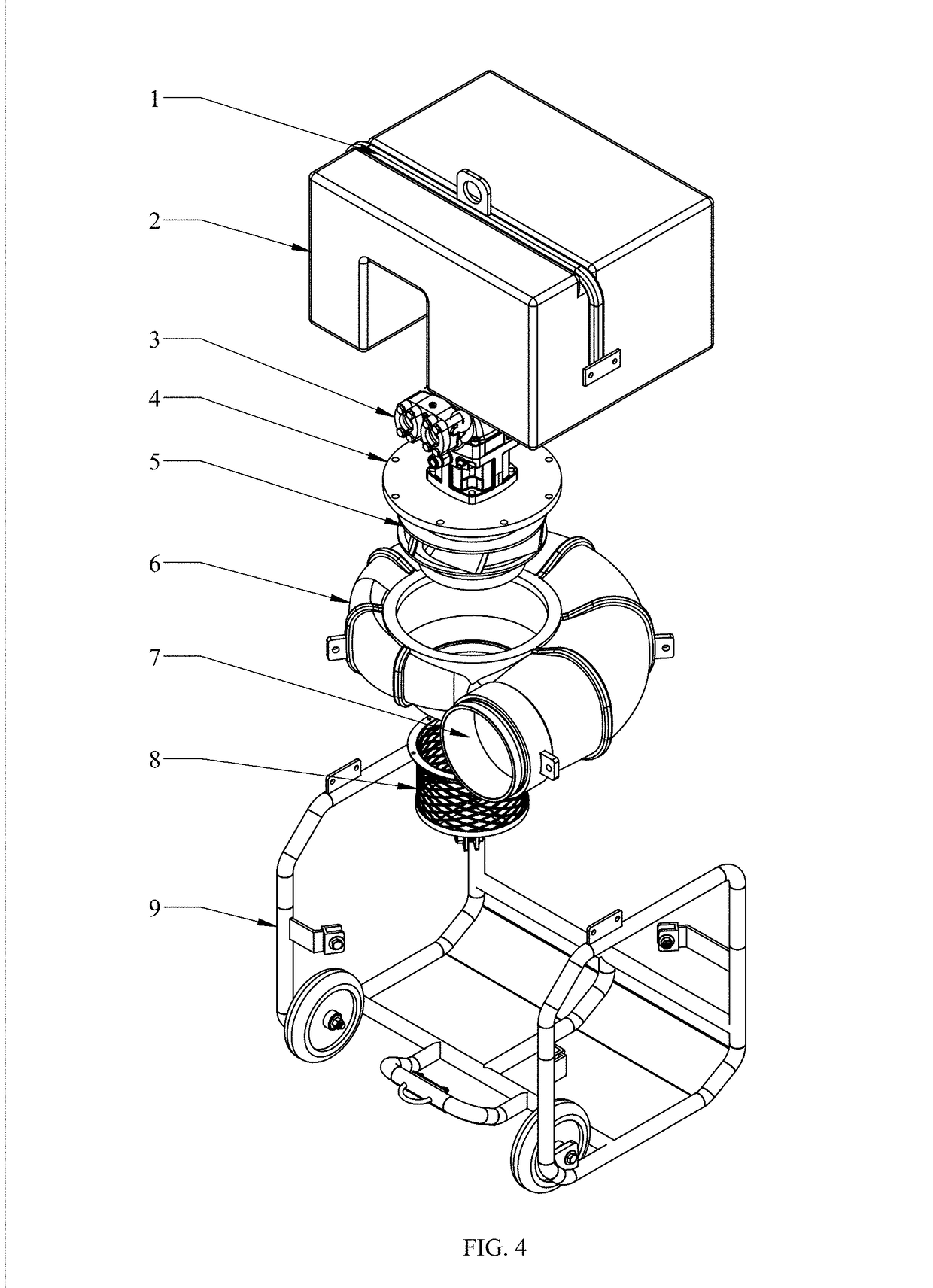

[0012]The composite constructed floating submersible water supply pump is specifically designed to be ultra-lightweight (comparable to other traditional metal technologies) and highly corrosion resistant to saline environments. By providing such a lightweight system, rapid system deployment for high-volume water transfer needs (such as in municipal de-flooding, FIG. 7) is made possible without the use of heavy equipment, instead substituted by manual manpower.

[0013]The composite floating submersible pump is manufactured using well understood commercial manufacturing concepts and intuitive tooling systems. The integral pontoon (FIG. 4, item 2) is made through rotational molding using economical thermoplastic polymers. The same pontoon can also be constructed from typical fiberglass hand layup methods. The motor (FIG. 4, item 3) is a standard commercially available hydraulic or electric motor capable of running submerged in water. The motor external body is sealed, and the surface is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Weight ratio | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com