Method for enhancing antifouling properties of high entropy alloys

a high entropy alloy and antifouling technology, applied in the field of high entropy alloys, can solve the problems of significant losses in the fishing industry, dramatic societal and economic costs, and fish in the fishing net to die off, and achieve the effects of enhancing antifouling properties, preventing the attachment of marine organisms, and high entropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Example 1

[0024]In Example 1 of the invention, a Co—Cr—Fe—Mn—Ni based high entropy alloy was used, having excellent mechanical properties and excellent corrosion resistance, which, in particular, is an essential property for marine structures and ships.

[0025]The specific composition of the alloy is 10 at % of Co, 15 at % of Cr, 25 at % of Fe, 10 at % of Mn, and 40 at % of Ni.

[0026]First, a specimen for a high pressure torsion process was prepared using a high entropy alloy sheet (the grain size of the sheet is 15 μm) having a diameter of 10 mm and a thickness of 1.5 mm, and a torsion process in which the sheet was rotated under a pressure of 5 GPa was performed 10 times in order to reduce the structure of the material.

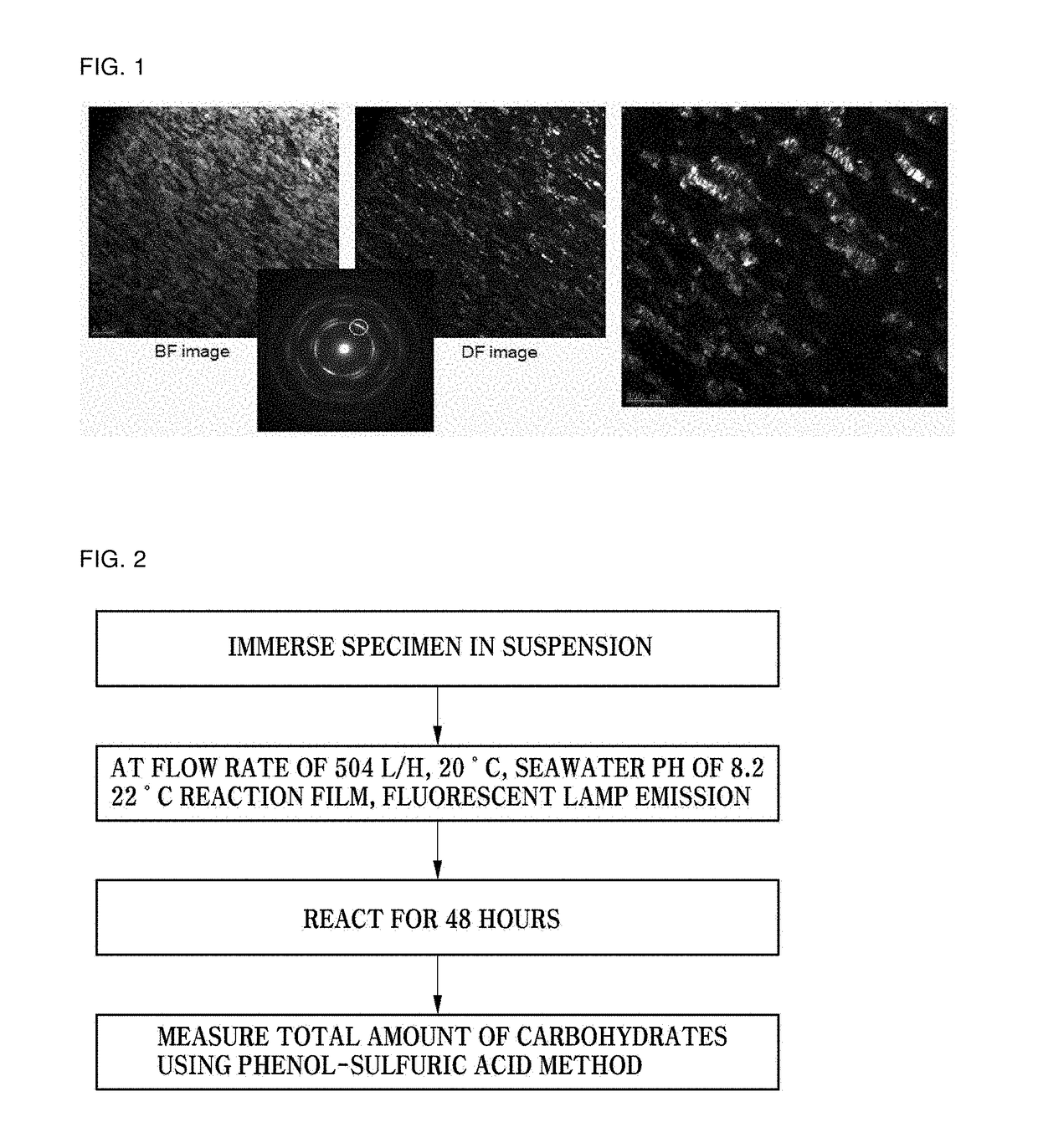

[0027]FIG. 1 is a photograph illustrating the microstructure of a high entropy alloy observed using transmission electron microscopy after a torsion process according to Example 1 of the invention is performed. As shown in FIG. 1, it was observed that the grains were re...

example 2

[0029]In order to confirm whether high pressure torsion deformation according to the invention can be used to obtain the same effect in other metal materials, a sheet (the grain size of the sheet is 20 μm) formed of STS304 stainless steel was prepared under the same conditions as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com