A steel rebar and a production method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

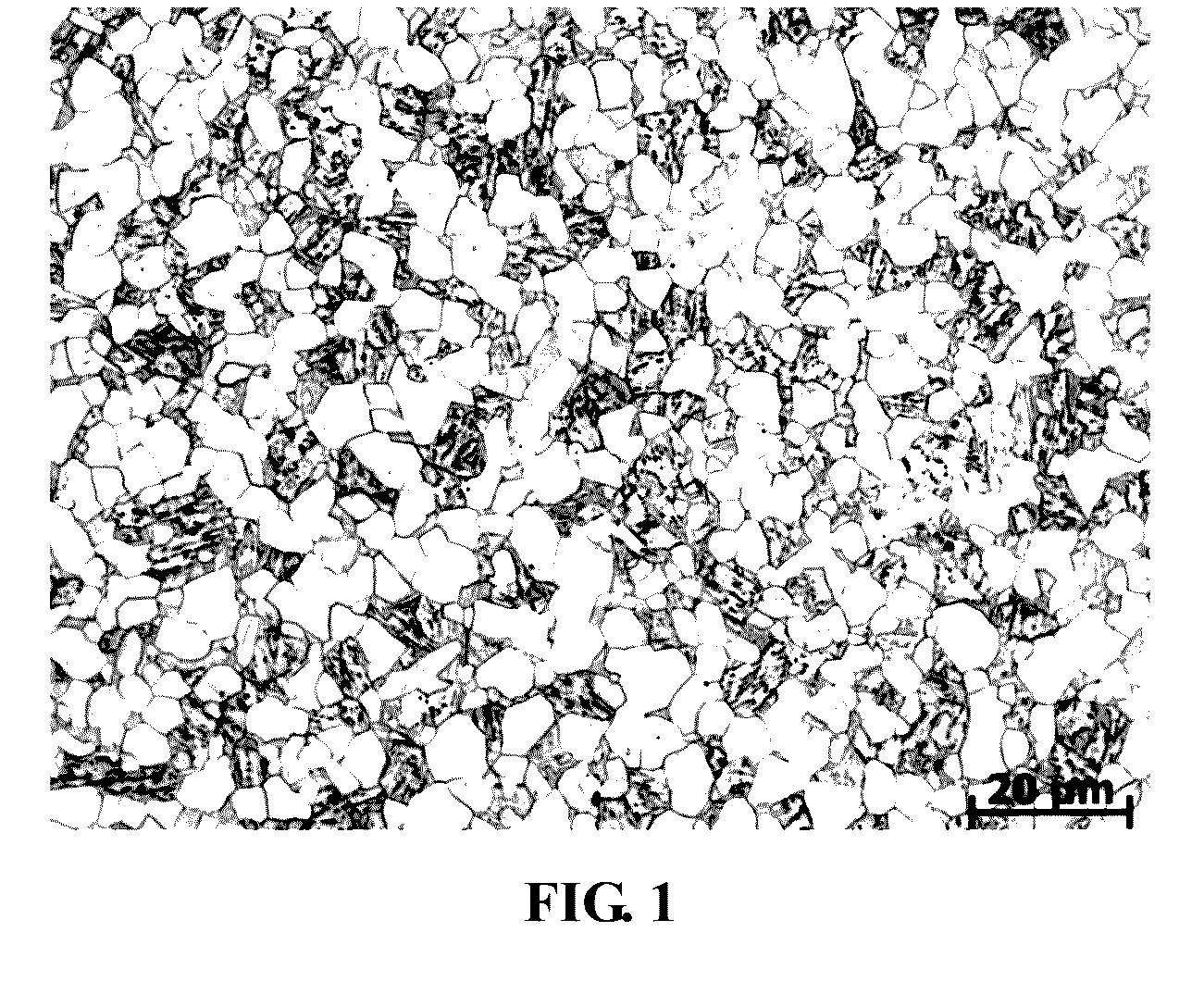

Image

Examples

embodiment 1

[0042]The present embodiment provides a steel rebar, comprising the following elements: C, Si, Mn, P, S, Cr, Mo, Sn, Rare Earth element, Fe and unavoidable impurities, wherein, the weight percentages of the ingredients are as shown in Table 1, the mechanical properties are as shown in Table 2, and the corrosion resistance performance is as shown in Table 3.

[0043]The present embodiment also provides a production method of steel rebar comprising the following steps:

S1: performing preliminary desulfurization of molten iron by using a KR method to control the sulfur content at no more than 0.01%. Because sulfur element as an impurity element would reduce mechanical properties and corrosion resistance performance of steel and normally cannot be removed in a convertor, therefore, in order to reduce the sulfur content in steel, preliminary desulfurization treatment needs to be performed in molten iron. Before performing desulfurization, the blast furnace slag needs to be removed in order t...

embodiment 2

[0044]The present embodiment provides a steel rebar, comprising the following elements: C, Si, Mn, P, S, Cr, Mo, Sn, Rare Earth element, Fe and unavoidable impurities, wherein, the weight percentages of the ingredients are as shown in Table 1, the mechanical properties are as shown in Table 2, and the corrosion resistance performance is as shown in Table 3.

[0045]The present embodiment also provides a production method of steel rebar comprising the following steps:

S1: performing preliminary desulfurization of molten iron by using a KR method to control the sulfur content at no more than 0.01%. Because sulfur element as an impurity element would reduce mechanical properties and corrosion resistance performance of steel and normally cannot be removed in a convertor, therefore, in order to reduce the sulfur content in steel, preliminary desulfurization treatment needs to be performed in molten iron. Before performing desulfurization, the blast furnace slag needs to be removed in order t...

embodiment 3

[0046]The present embodiment provides a steel rebar, comprising the following elements: C, Si, Mn, P, S, Cr, Mo, Sn, Rare Earth element, Fe and unavoidable impurities, wherein, the weight percentages of the ingredients are as shown in Table 1, the mechanical properties are as shown in Table 2, and the corrosion resistance performance is as shown in Table 3.

[0047]The present embodiment also provides a production method of steel rebar comprising the following steps:

S1: performing preliminary desulfurization of molten iron by using a KR method to control the sulfur content at no more than 0.01%. Because sulfur element as an impurity element would reduce mechanical properties and corrosion resistance performance of steel and normally cannot be removed in a convertor, therefore, in order to reduce the sulfur content in steel, preliminary desulfurization treatment needs to be performed in molten iron. Before performing desulfurization, the blast furnace slag needs to be removed in order t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com