Bag opener component for plastic bag dispenser

a plastic bag dispenser and bag opener technology, applied in the field of accessories, can solve the problems of difficult opening, thin plastic layer adhesion, and lack of separating means of the plies, and achieve the effect of sufficient friction coefficient and adequate rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Referring to FIGS. 1-8B, the bag opener component of the present invention includes a friction element and a means of mounting to an existing bag roll dispenser in such a way as to enable bags to be presented in a partially opened state.

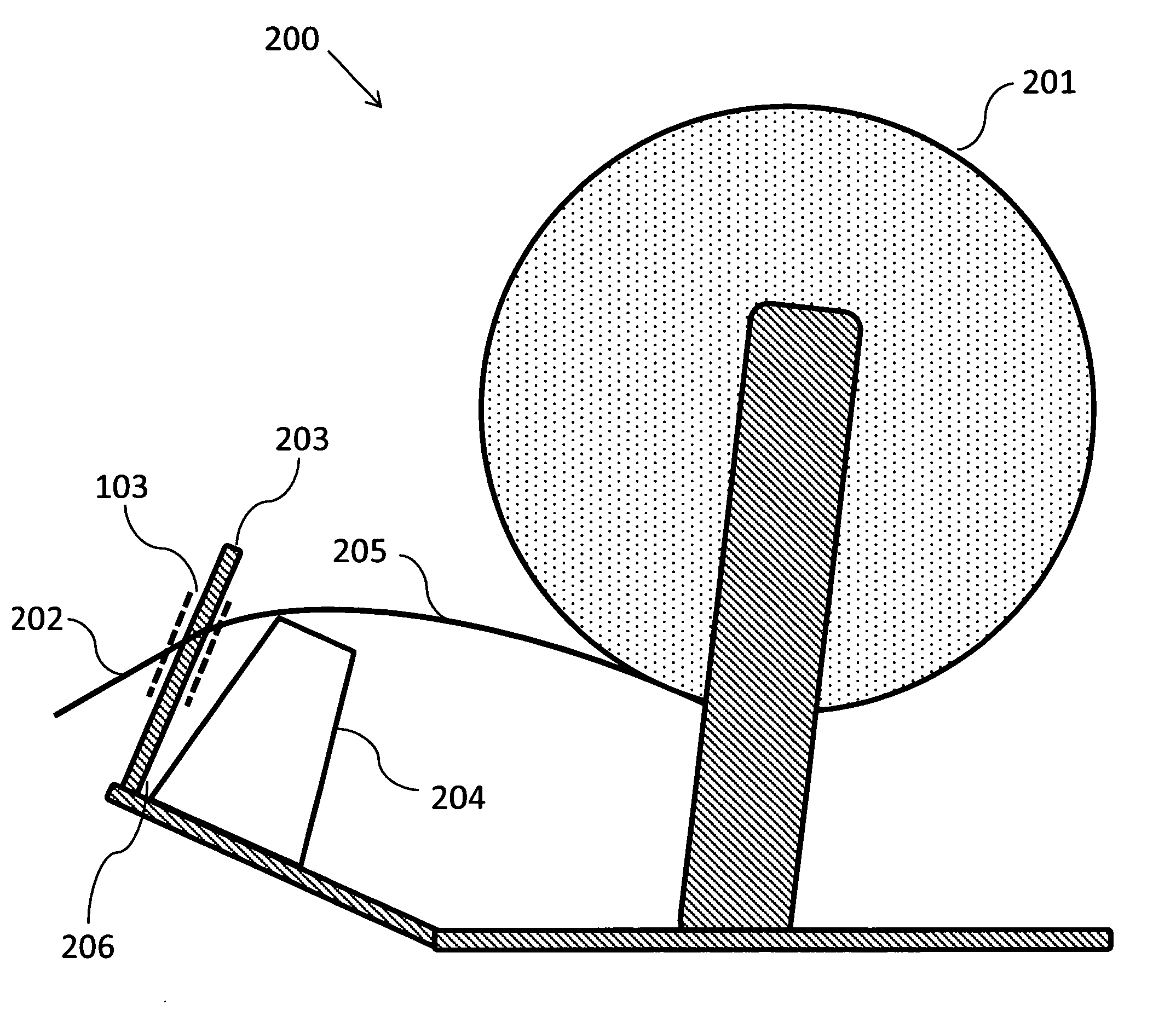

[0025]FIG. 1 illustrates a typical bag design of the type standardly referred to as “star seal.” The bag 100 is formed from a tube of thin film plastic that is folded or gusseted creating multiple bag plies. Each bag is welded at one end 101 to form the bag bottom and releasably attached to the next bag by means of a perforation line 102. A slot 103 in the perforation line provides an opening to facilitate separation. A continuous strip of bags is wound on a roll for dispensing in a bag dispenser.

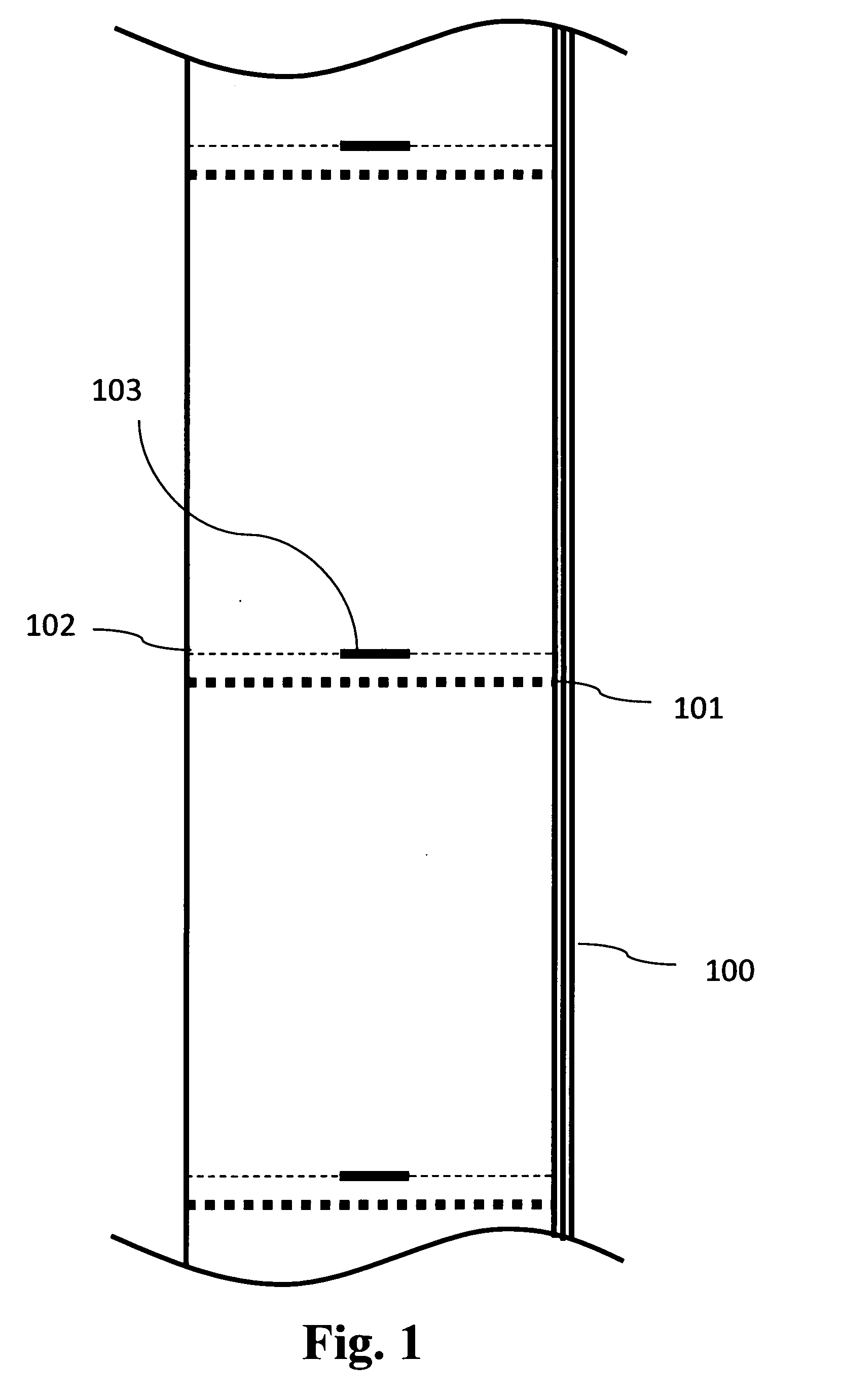

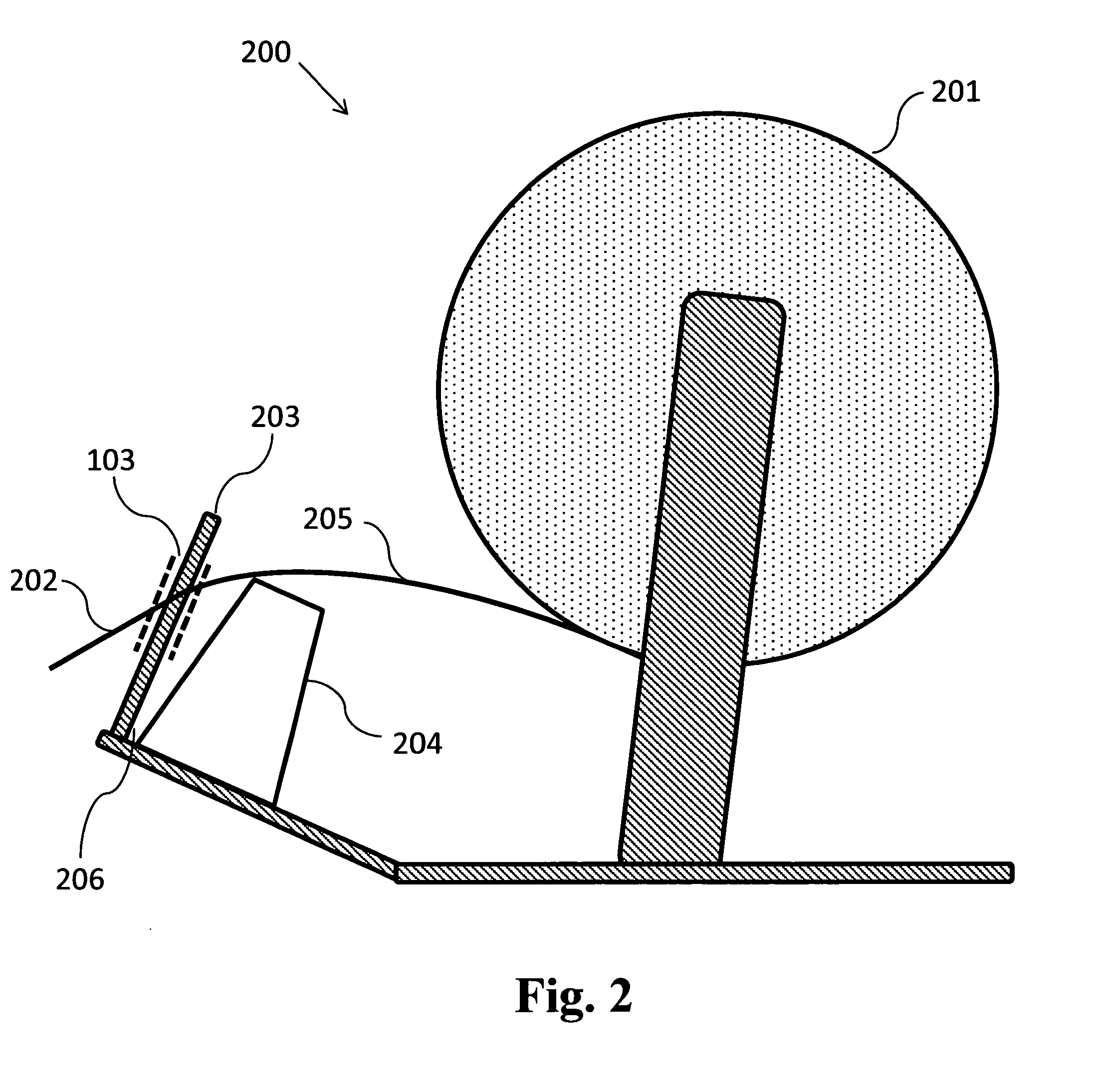

[0026]FIG. 2 is a functional illustration of a typical bag dispenser 200 for a roll of bags 201 constructed as described above. As a single bag 202 is dispensed, a tongue 203 engages a slot 103 in the perforation line between the bag being dispensed 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com