Scrubber, exhaust gas purification system comprising scrubber, and air purification method

a technology of scrubber and scrubber, which is applied in the direction of dispersed particle separation, waste water treatment from gaseous effluent, and separation processes, etc., can solve the problems of limited purification efficiency, secondary pollution, and inability to be widely used in civil and industrial applications, and achieves excellent air purification capability, high efficiency, and simple exhaust gas treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

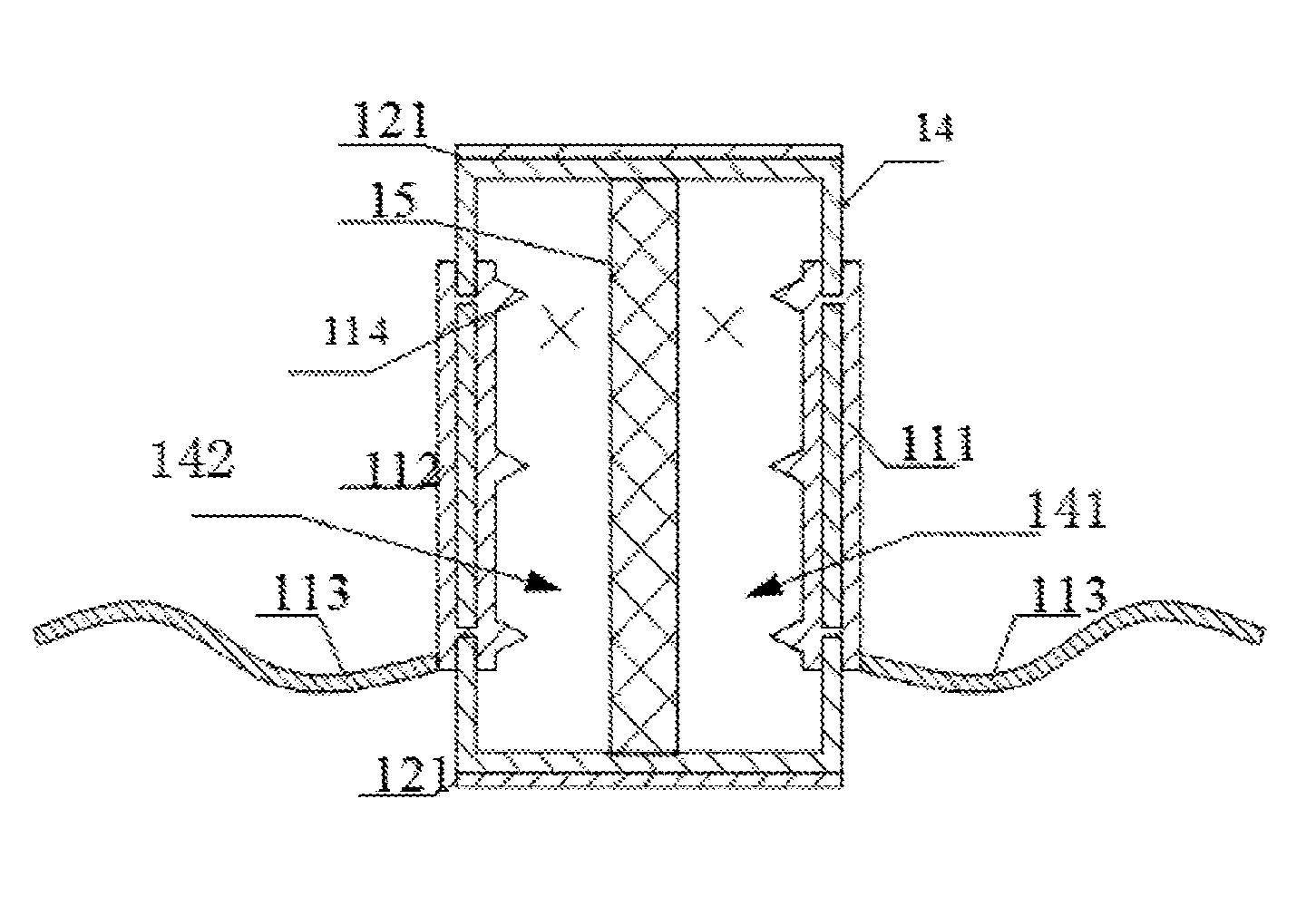

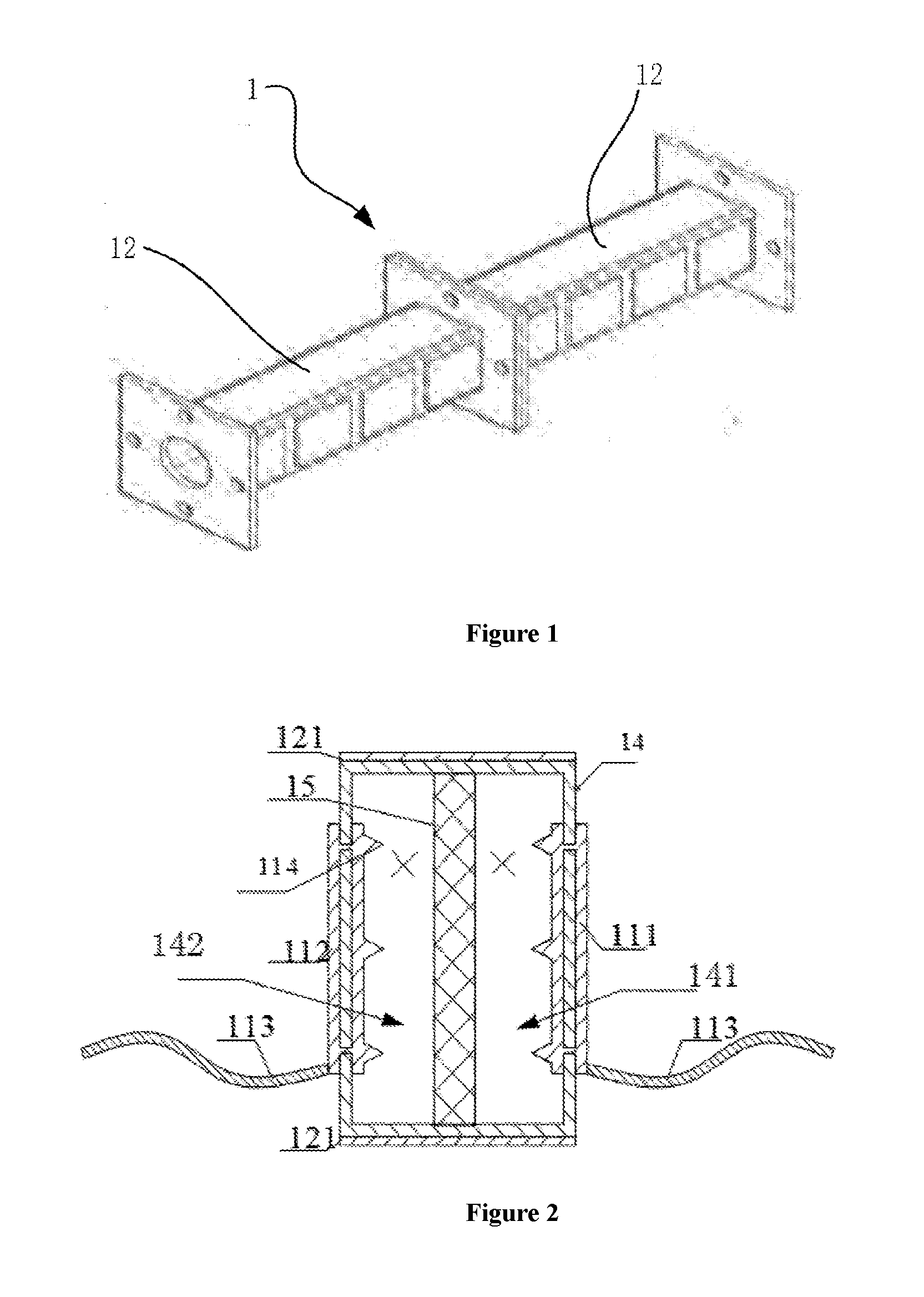

[0044]FIGS. 1 and 2 illustrate an electromagnetic water treatment device 1 of the present invention. The electromagnetic water treatment device 1 comprises a cation exchange film 15, a water flow passage 14, at least one positive pole panel 111 and at least one negative pole panel 112, and a magnetic device 12; the positive pole panel 111 and the negative pole panel 112 are disposed on the water flow passage, and applied an electric field, to electrolyze the solution in the water flow passage; the cation exchange film 15 is disposed inside the water flow passage 14, is located between the positive pole panel and the negative pole panel, and divides the water flow passage 14 into a first water flow passage 142 and a second water flow passage 141; the magnetic device 12 is disposed on the water flow passage, to apply a magnetic field perpendicular to the direction of the electric field in the water flow passage, and in the present embodiment, the magnetic device is a plurality of magn...

embodiment 2

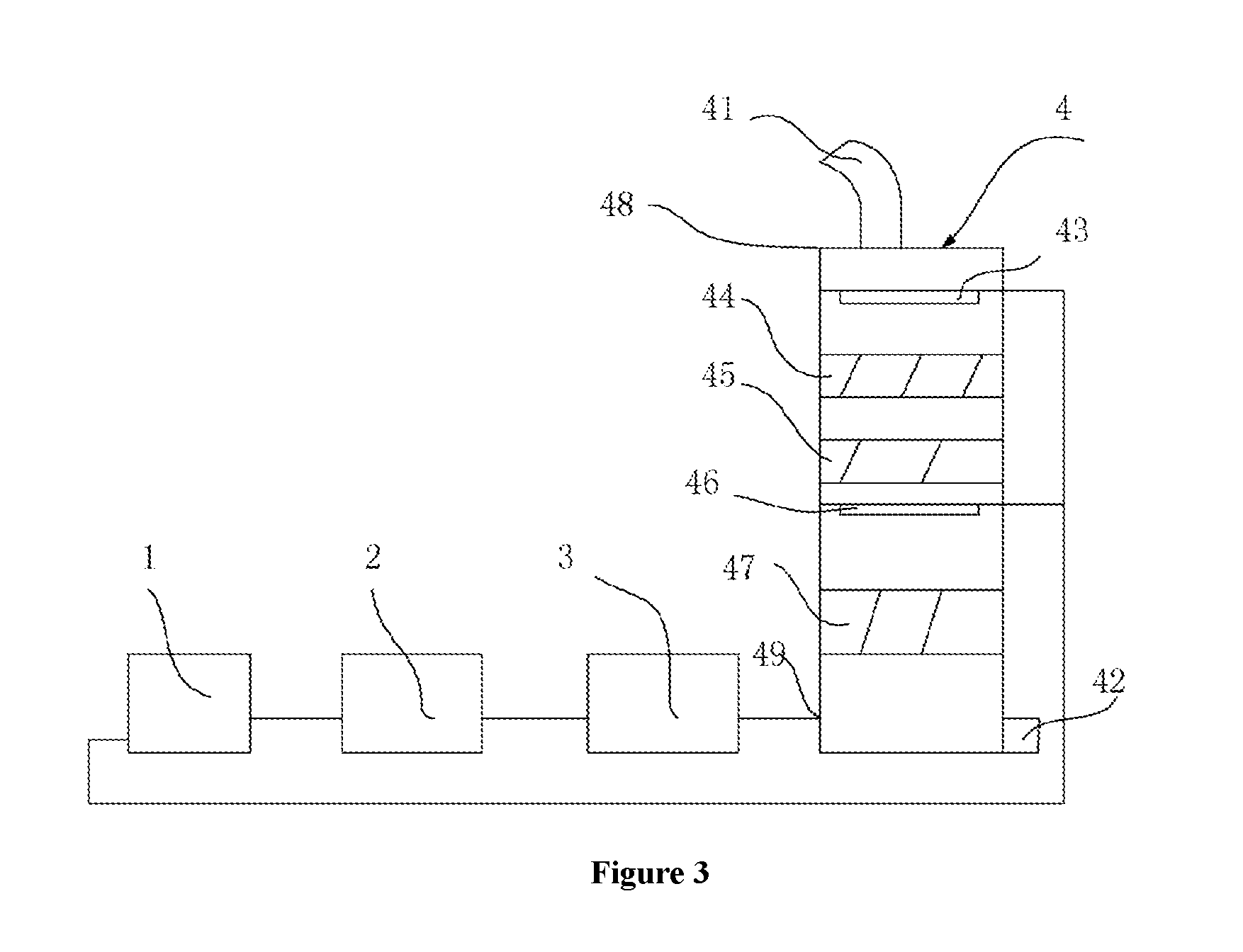

[0046]As shown in FIG. 3, the present embodiment provides an exhaust gas purification system, the exhaust gas purification system comprises an electromagnetic water treatment device 1, a scrubber 4, a filter 3, and a water tank 2; the electromagnetic water treatment device 1, the scrubber 4, the filter 3, and the water tank 2 are circularly connected in turn. The scrubber 4 comprises an gas inlet 42, a tower tube 48, a gas outlet 41, and a water outlet 49; two nozzles, and three filler layers are disposed inside the tower tube 48, from the top to the bottom a first nozzle 43, a first filler layer 44, a second filler layer 45, a second nozzle 46 and a third filler layer 47 are disposed in turn.

[0047]Water from the water tank 2 enters the electromagnetic water treatment device 1 after being electrolysed to obtain plasma electrolytic water of the present invention, the plasma electrolytic water is sprayed to the first filler layer 44, the second filler layer 45 and the third filler lay...

embodiment 3

[0048]The present embodiment is substantially the same as embodiment 2, except that, using a reactor continuously generating high redox water in embodiment 1 of Chinese patent application having an authorization publication No.: CN102320684B of invention patent (the content of which is incorporated herein by reference in its entirety) to replace the electromagnetic water treatment device 1 in the embodiment 2 of the present invention. The height of the filler layer in the scrubber is 2 m, and the gas superficial velocity in the scrubber is 0.5 m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic field intensity | aaaaa | aaaaa |

| filling height | aaaaa | aaaaa |

| superficial velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com