Method for electrolytic surface modification of flat metal workpieces in copper-sulfate treatment liquid containing sulfate-metallates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

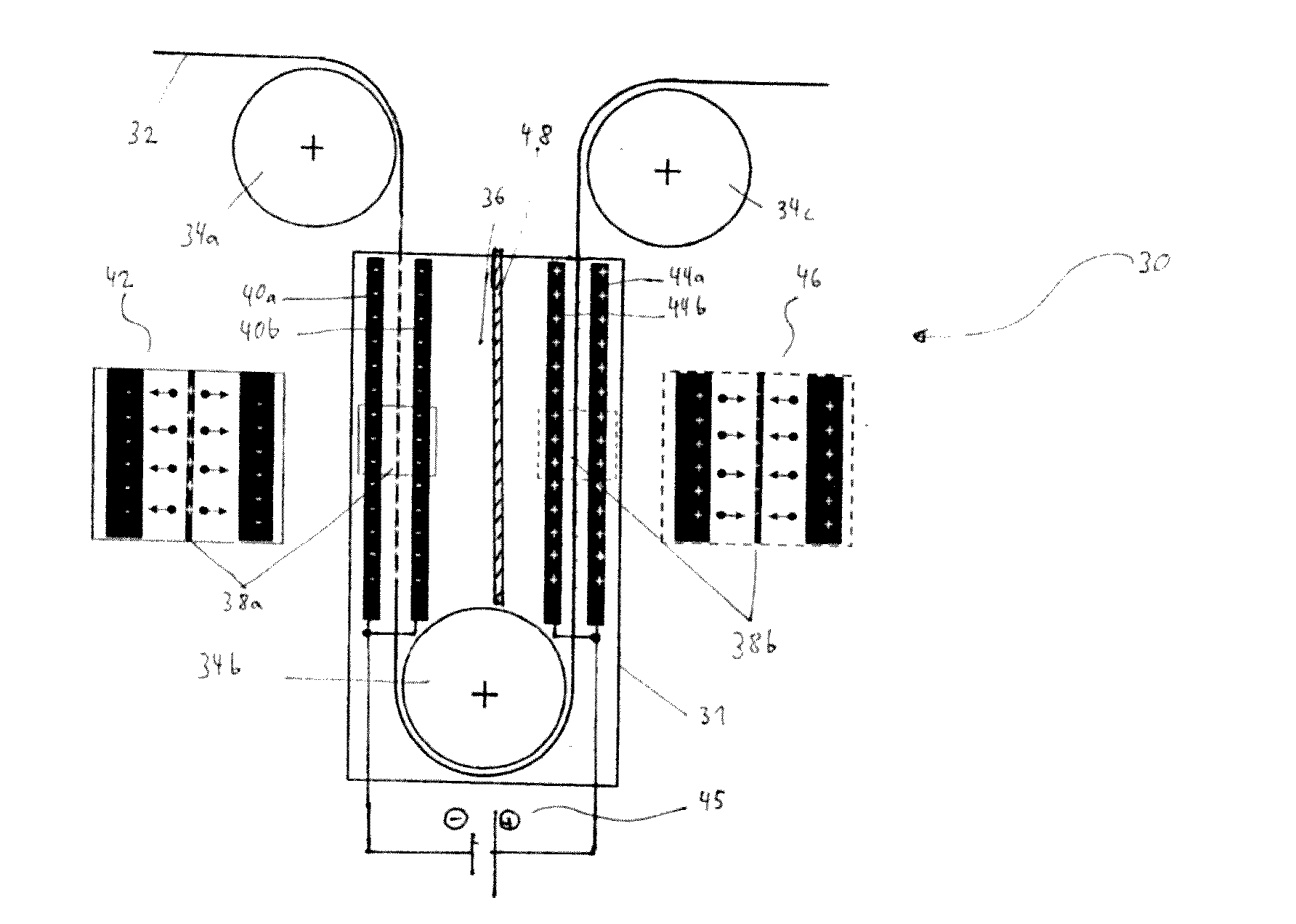

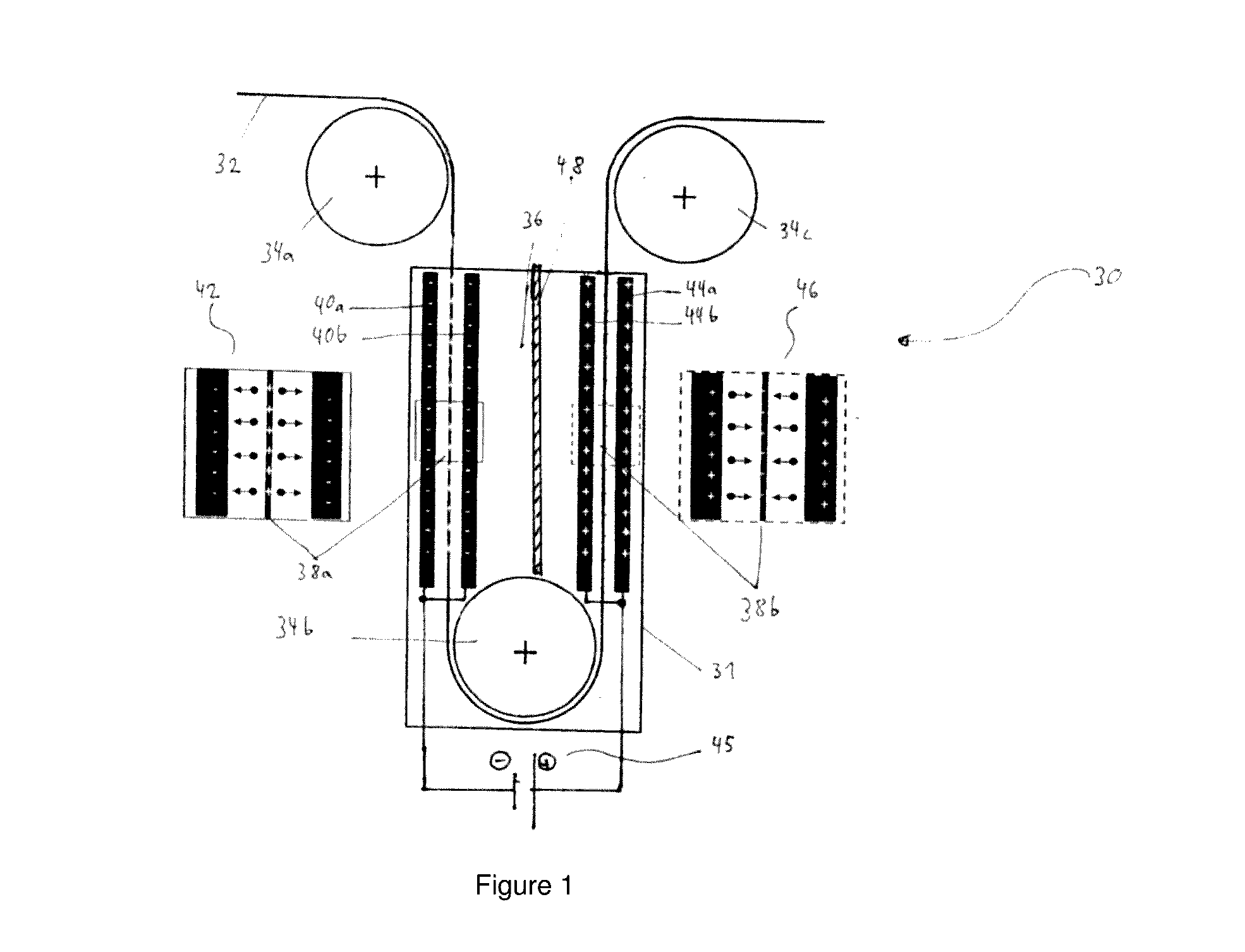

Method used

Image

Examples

example 1

Copper Deposition on Copper Foil by Means of a Continuous Foil Installation Using Different Sulphuric Acid Copper Electrolytes with or without Addition of La Conducting Salt

[0112]A copper foil with a thickness of 0.035 mm and a width of 300 mm in the hard-as-rolled structural state was first subjected to a pre-treatment which comprised the following steps in the stated sequence:[0113]Degreasing: Immersion pass with electrolytic support, 45° C., alkaline cleaning agent[0114]Rinse: Water, immersion pass, 45° C.[0115]Pickling: Sulphuric acid 4% in water, immersion pass, 30-35° C.[0116]Rinse: Water, immersion pass, room temperature[0117]Rinse: Water, immersion pass, room temperature

[0118]The copper foil pre-treated in this way was then surface-modified in the described continuous foil installation using the electrolytes of Table 4 (Electrolyte 0, Electrolyte 1, Electrolyte 2, Electrolyte 3) and with the following method parameters:

[0119]Strip speed: 1 m / min.,

[0120]Average current streng...

example 2

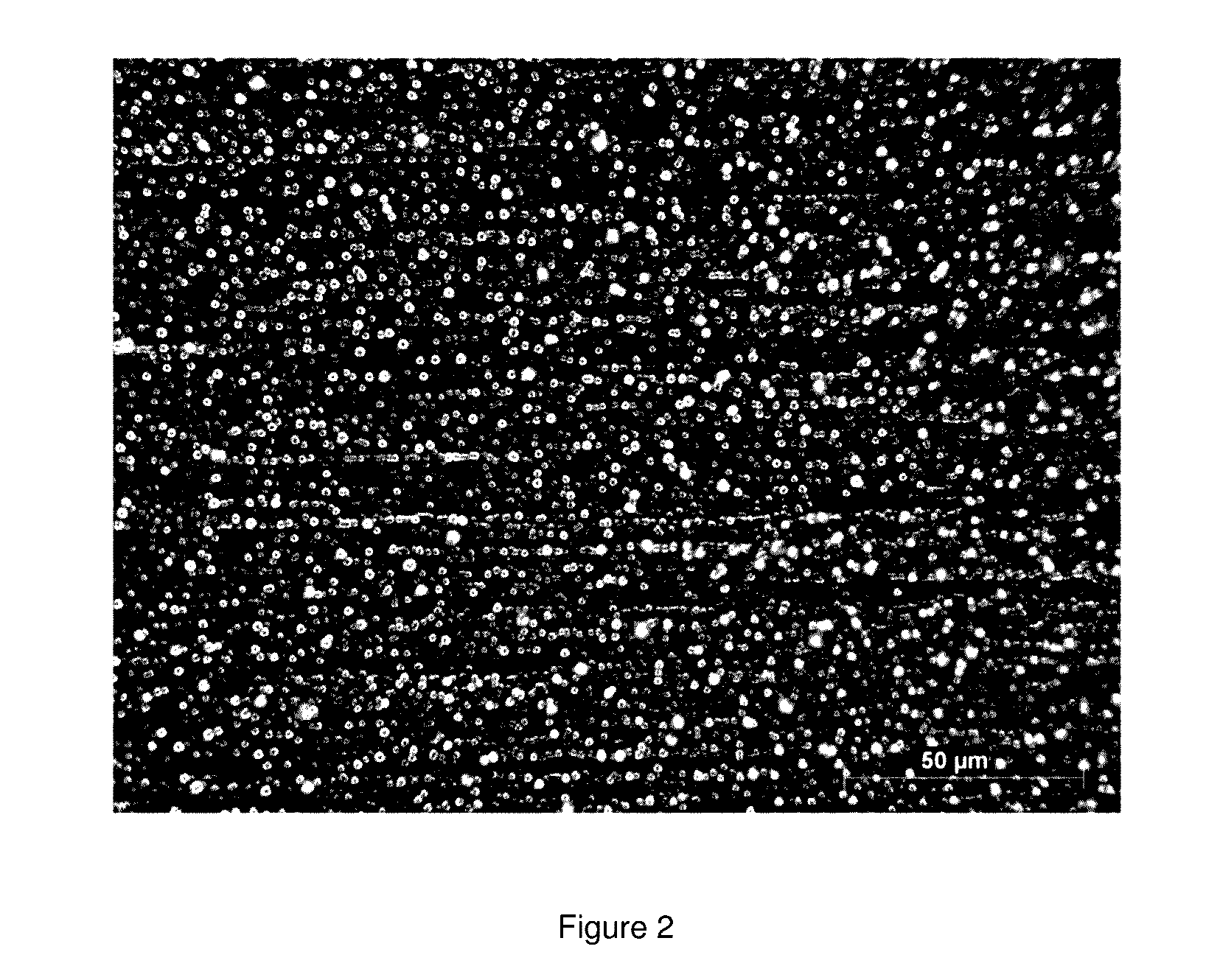

Incorporation of Rare Earth Elements (REE) into the Aggregates on the Surface of Copper Foil Modified with REE-Cu Electrolytes

[0134]A copper foil with a thickness of 0.035 mm and a width of 300 mm in the hard-as-rolled structural state was first of all subjected to a pre-treatment which comprised the following steps in the stated sequence:[0135]Pre-cleaning: Purax 6029PUS, 40 g / l, 60° C., currentless, 10 s.[0136]Rinse: Water[0137]Precision cleaning: Velocit 1127M, 25 g / l, 60° C., currentless, 10 s.[0138]Rinse: Water[0139]Etching / pickling: Sulphuric acid (7% in water), 25° C.-35° C.[0140]Rinse: Water

[0141]The copper foil pre-treated in this way was then surface-modified in the described static electrolysis arrangement using Electrolyte 1 and Electrolyte 2 at room temperature with a charge density of 541 C / dm2:

[0142]After passing through the electrolysis apparatus, the surface-modified copper foil was subjected to an after-treatment which comprised the following steps in the stated se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com