Optical disc drive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

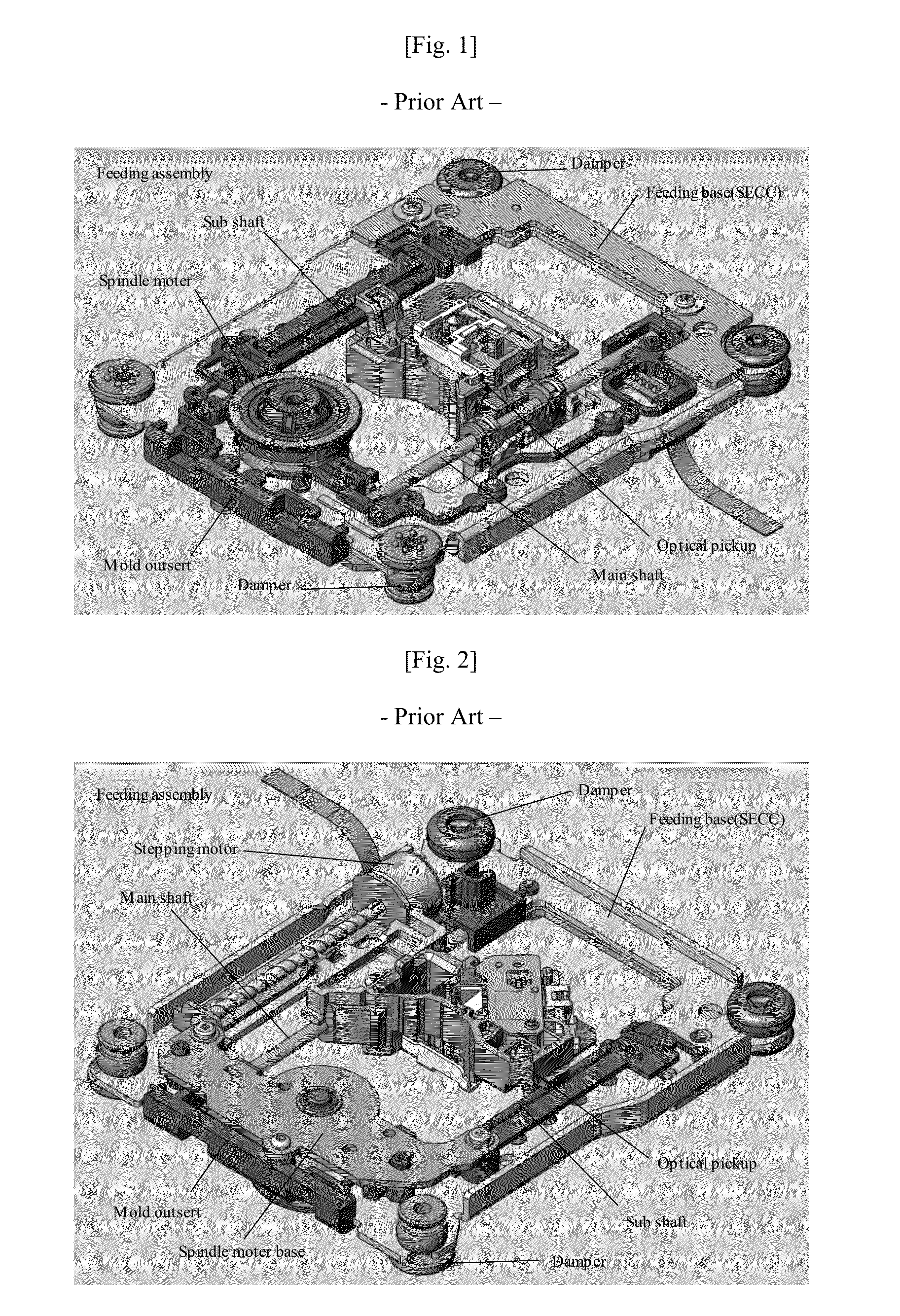

Image

Examples

Embodiment Construction

[0029]The above object, characteristics, and merits of the present invention will become more apparent from the following detailed description taken in conjunction with the accompanying drawings. The present invention may be modified in various ways and may have some embodiments. Hereinafter, some exemplary embodiments of the present invention will be illustrated in the accompanying drawings and described in detail. The same reference numerals basically designate the same elements throughout the drawings. Furthermore, in describing the present invention, a detailed description of known functions or elements relating to the present invention will be omitted if it is deemed to make the gist of the present invention unnecessarily vague. Numbers (for example, the first and the second) used to describe the present invention are merely identification symbols for distinguishing one element from the other element.

[0030]Hereinafter, the feeding base of an optical disc drive according to an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com