Harsh environment pressure compensator for inline cable termination

a compensator and inline cable technology, applied in the direction of coupling device connection, borehole/well accessories, instruments, etc., can solve the problems of not being as durable as metallic materials, the shell and housing of prior art devices are typically very thick to withstand collapsing, etc., to reduce the amount of compressible gas contained, simplify the exterior shape and assembly, and reduce the effect of outside pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

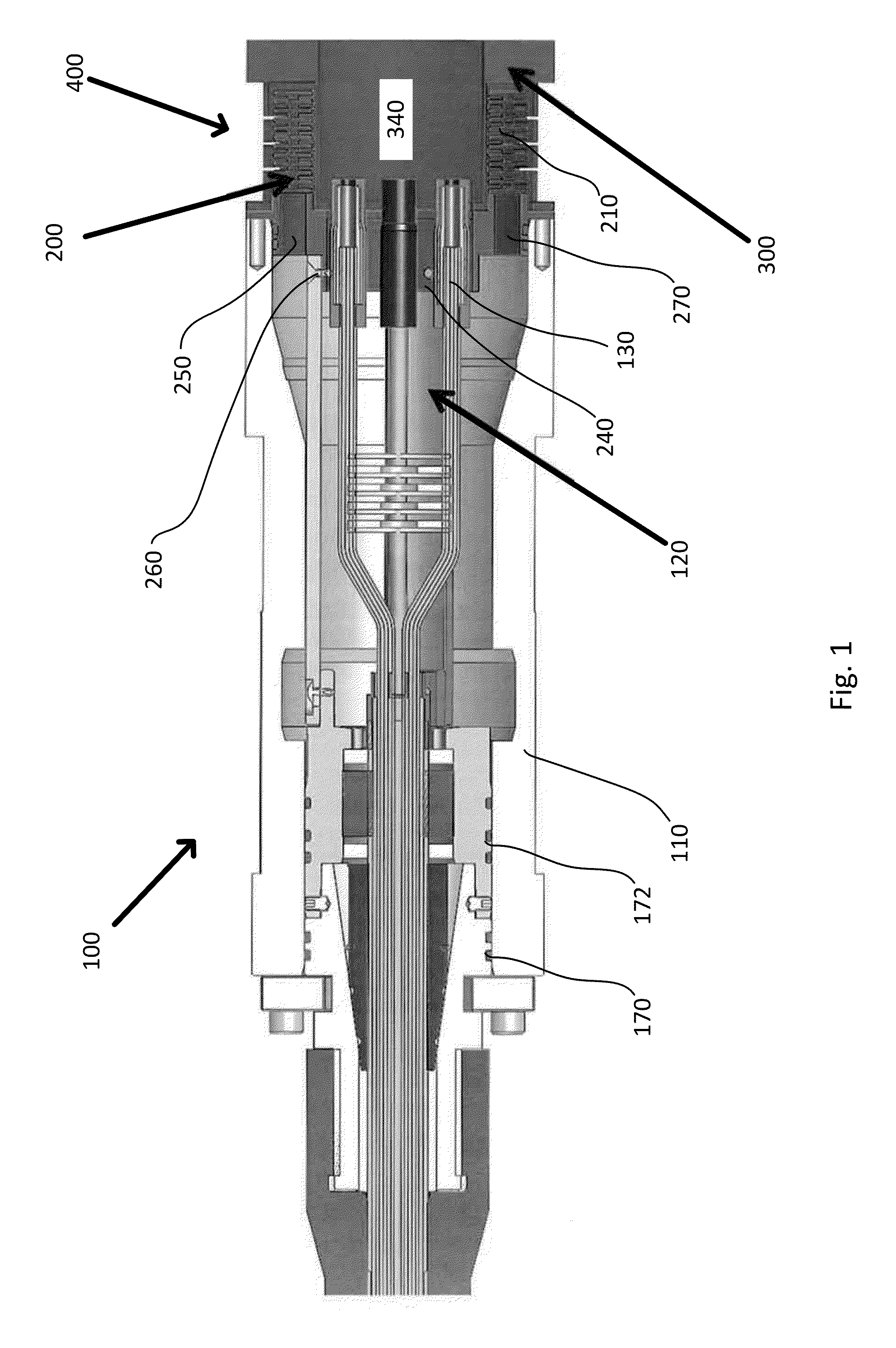

[0035]The present invention and system will now be described in more detail with reference to exemplary embodiments as shown in the accompanying drawings. While the present invention and system is described herein with reference to the exemplary embodiments, it should be understood that the present invention and system is not limited to such exemplary embodiments. Those possessing ordinary skill in the art and having access to the teachings herein will recognize additional implementations, modifications, and embodiments as well as other applications for use of the invention and system, which are fully contemplated herein as within the scope of the present invention and system as disclosed and claimed herein, and with respect to which the present invention and system could be of significant utility.

[0036]The present invention generally relates to an inline pressure compensator that compensates for volumetric changes within Field-Assembled Cable Termination (FACT) structures when expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com