Needlefree valve device

a valve device and needle-free technology, applied in the direction of other medical devices, tube connectors, engine components, etc., can solve the problem of high manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

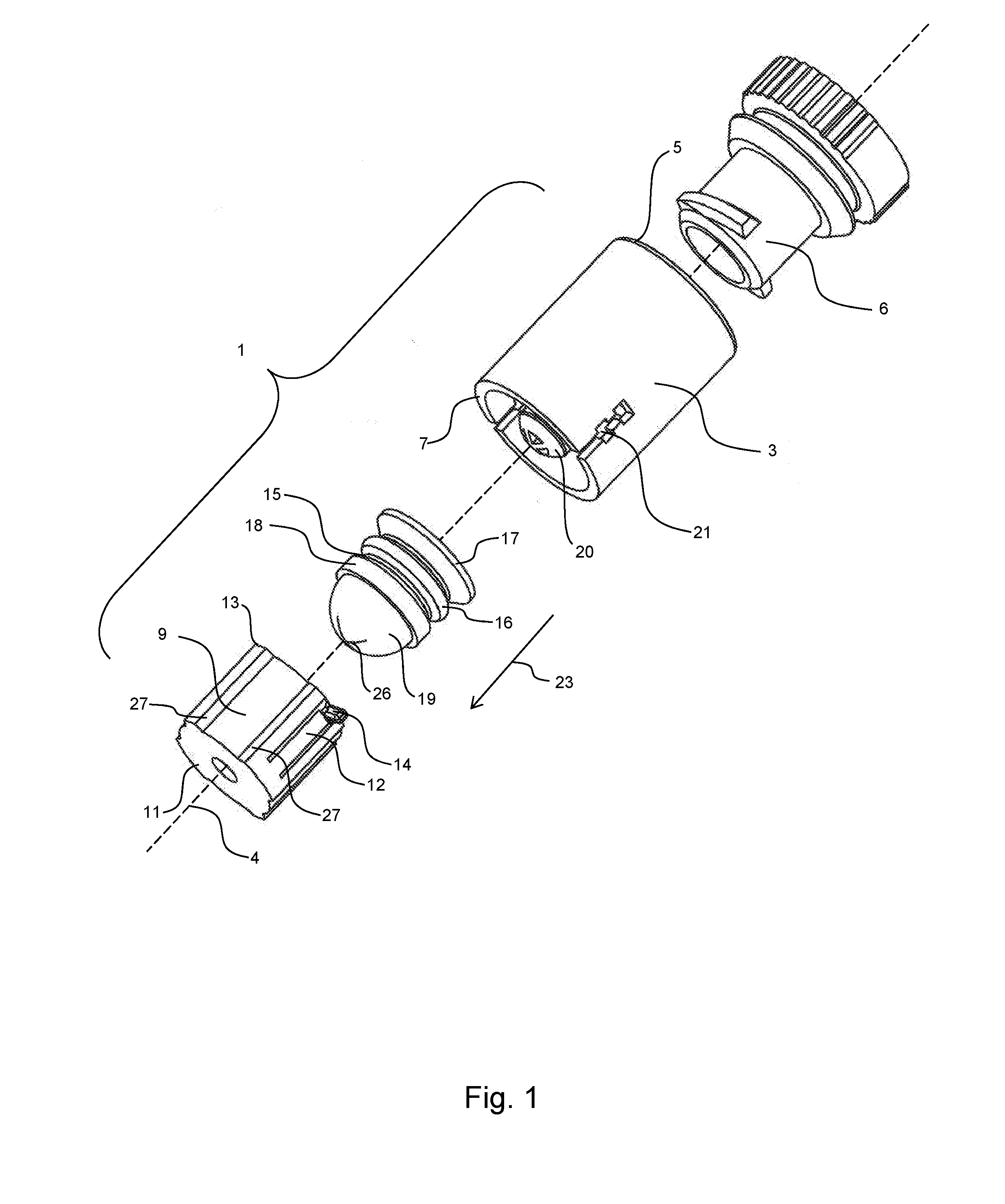

first embodiment

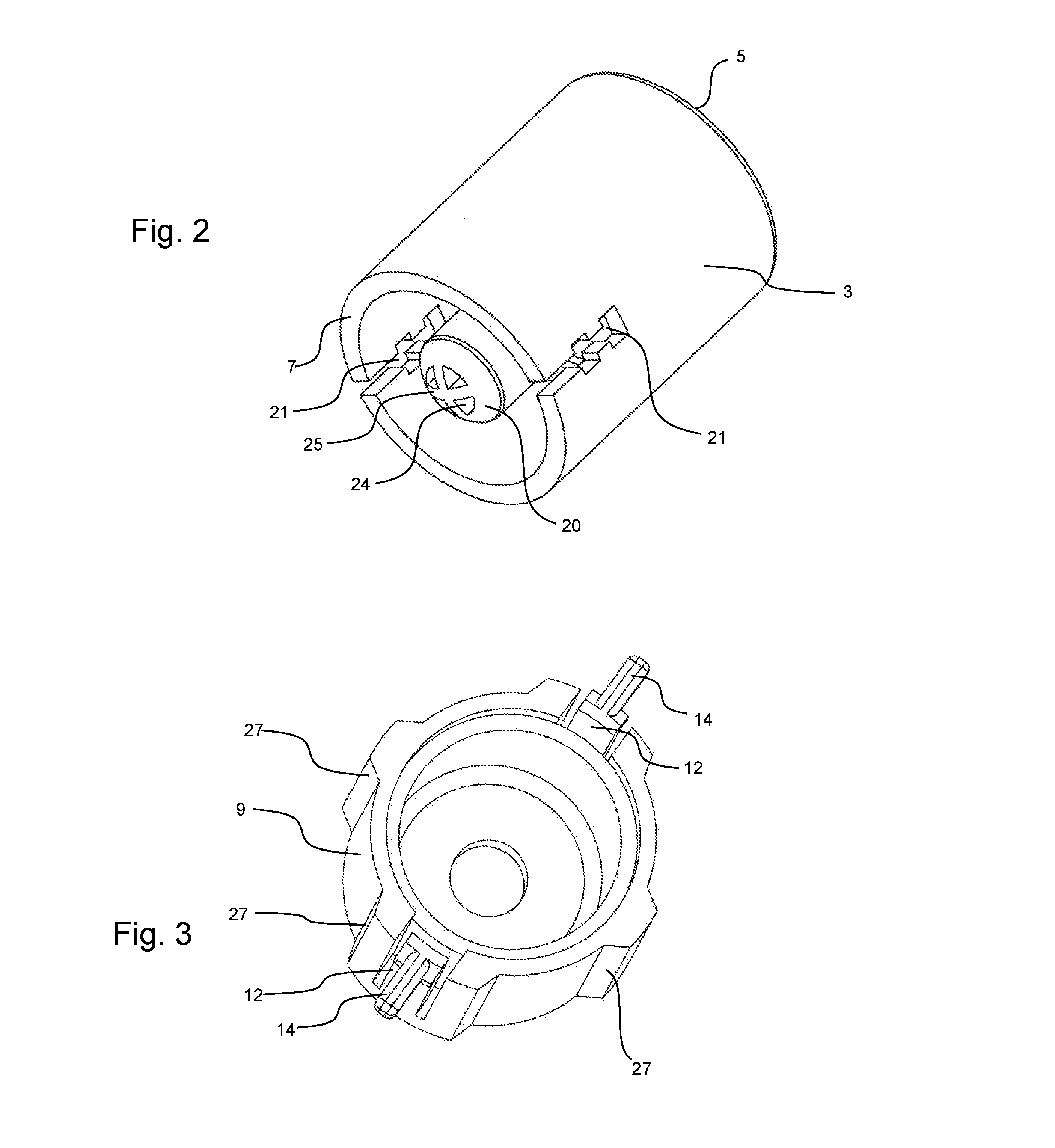

[0044]FIG. 2 is a detailed view of the first component of the valve device shown in FIG. 1. Beyond what was described with respect to FIG. 1, the male protrusion within the inside of sleeve-like first component 3 is clearly visible having a hemispherical contact surface 20 with four divider elements 25 and four flow channels 24 which enable fluid flow in the open configuration of the valve device. It should be noted that the shape of the male protrusion with convex contact surface 20 can be different from hemispherical. It may assume a planar, flat shape or a different curved shape. The main criterion for the shape of the protrusion and its contact surface is that it matches the inner surface of the first resilient portion 19 of sealing component 15 and its slit configuration as will be explained in greater detail below. In addition, a sufficient fluid flow through the flow channels 24 must be achieved. It should also be noted that the number of flow channels 24 and corresponding di...

second embodiment

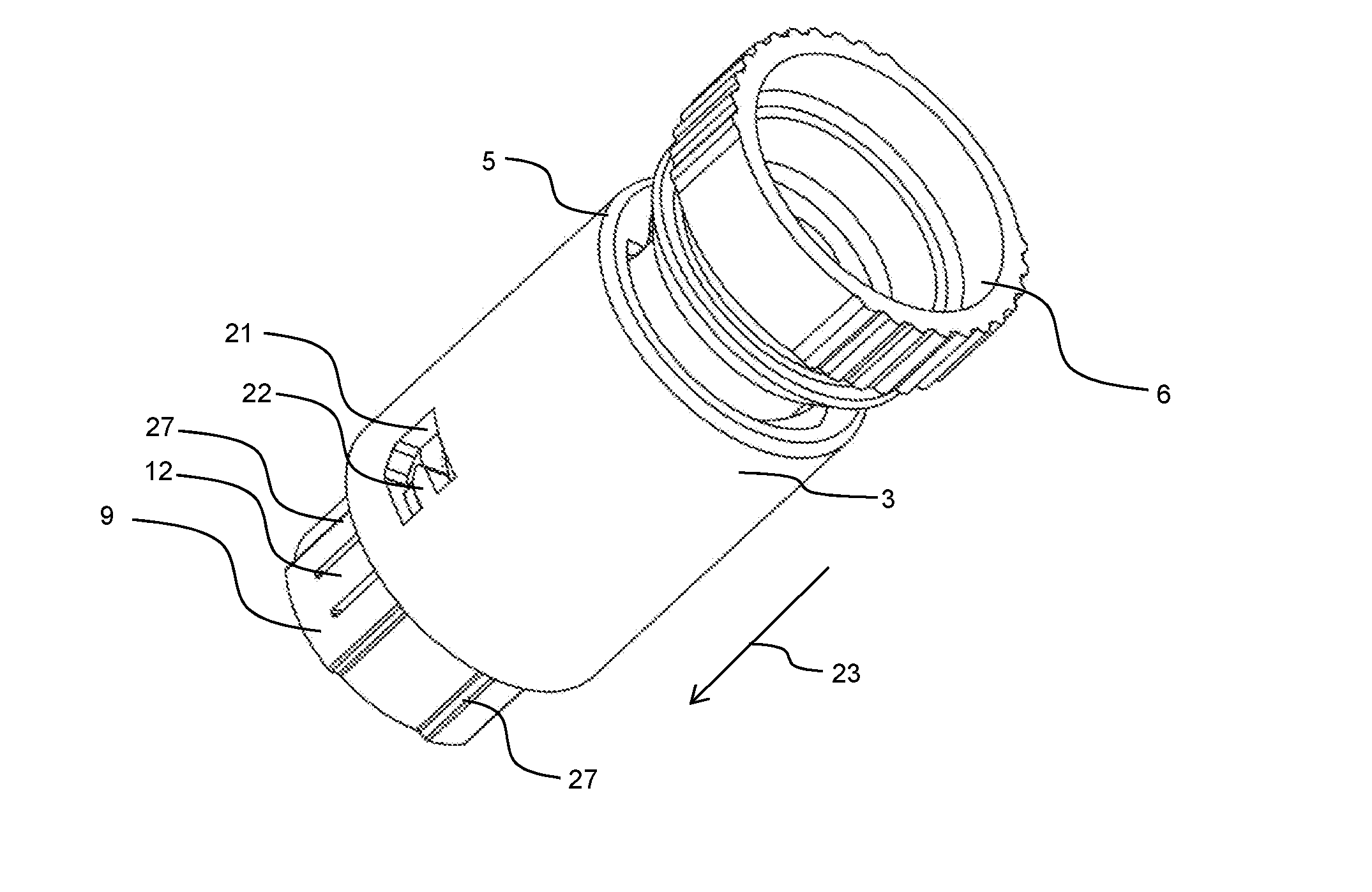

[0054]Recess 21 of first component 3 comprises a substantially rectangular or C-shaped configuration with a larger extension in the circumferential direction than in the axial direction parallel to the opening axis 23. Approximately in the middle of the longitudinal extension of recess 21 there is a locking arm 22 extending in a circumferential direction into recess 21 giving recess 21 a C-shape. In the embodiment shown as the second embodiment in FIGS. 7 to 17 the locking arm 22 extends from the right side wall in the outer surface of first component 3. The reason for this arrangement of locking arm 22 within recess 21 will become clear with respect to the detailed description of FIGS. 14 to 17 below.

[0055]The difference between the first and the second embodiment with respect to the locking mechanism is that in the second embodiment of FIG. 7 the free end of latch 12 near the valve end 13 does not comprise a grip protrusion 14 as in the first embodiment. This means that in the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com