Microalgal flour compositions of optimised sensory quality

a technology of microalgal flour and sensory quality, applied in the direction of dairy products, separation processes, instruments, etc., can solve the problems of poor or unacceptable organoleptic quality, association of organic compounds with a medium, etc., and achieve the effect of optimizing organoleptic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Definition of the Sensory Test

[0116]Sensory Test Conventionally Carried Out

[0117]The perception of a microalgal flour composition is generally determined by solubilization in water, the neutral medium par excellence.

[0118]A sensory panel was therefore formed to evaluate the sensory properties of various batches of microalgal flour, prepared according to the teaching of patent application WO 2010 / 12093.

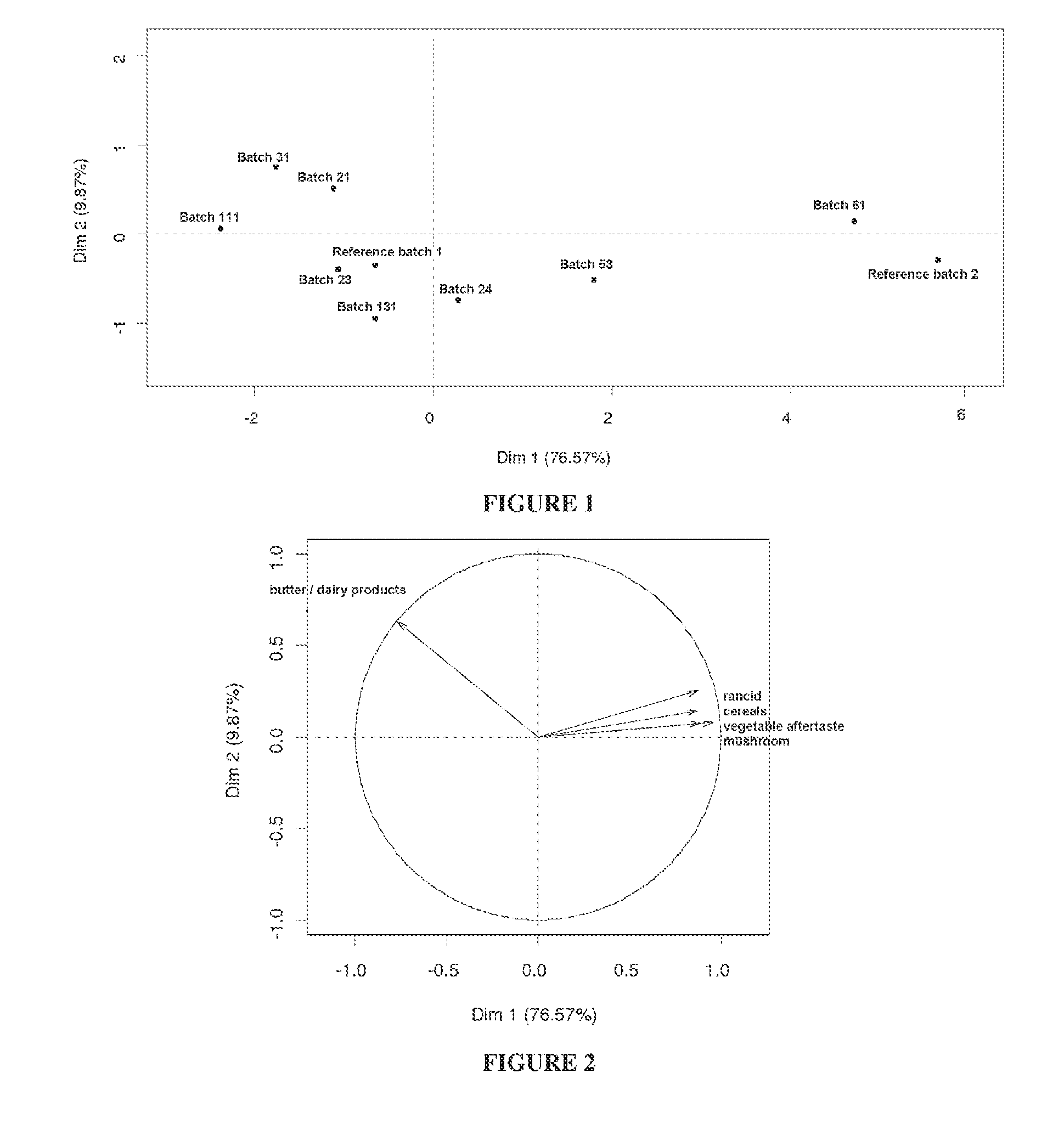

[0119]Eight batches of microalgal flour were tested: batch 21, batch 23, batch 24, batch 31, batch 53, batch 61, batch 111 and batch 131, in comparison with a reference sample identified as complying or acceptable (reference batch No. 1) and another, very unacceptable, batch (reference batch No. 2).

[0120]A set of 14 individuals were brought together to produce descriptors with respect to a microalgal flour composition considered to be complying (reference batch 1), said composition being placed in aqueous solution at 10% at ambient temperature (until homogenization).

[0121]The list of d...

example 2

Identification of the Volatile Organic Compounds (VOCs), by SPME / GC-MS, Associated with Unacceptable Off-Notes Organoleptic Classifications

[0184]In order to carry out the SPME / GC-MS analysis of the various batches of microalgal flour compositions, the process is carried out as follows.

[0185]A test specimen of 3 g of sample is introduced into a sealed SPME flask (20 ml) and incubated at 60° C. for 15 min and then extracted at 60° C. for 45 min with a DVB / CAR / PDMS (abbreviation for divinylbenzene / carboxen / polydimethylsiloxane, df 50 / 30 μm) SPME fiber.

[0186]The volatile organic compounds extracted are desorbed in the injector of the TSQ GC-MS system from Thermo Scientific, and then separated on a CPwax52 (60 m×0.25 mm, 0.25 μm) column with helium gas at 1.5 ml / min.

[0187]The temperature program is: 50° C. isotherm for 3 min, then programming at 5° C. / minute up to 230° C., then isotherm for 20 min.

[0188]The detection is carried out by electron impact (EI) mass spectrometry and the compou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com