Powered Shingle Remover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

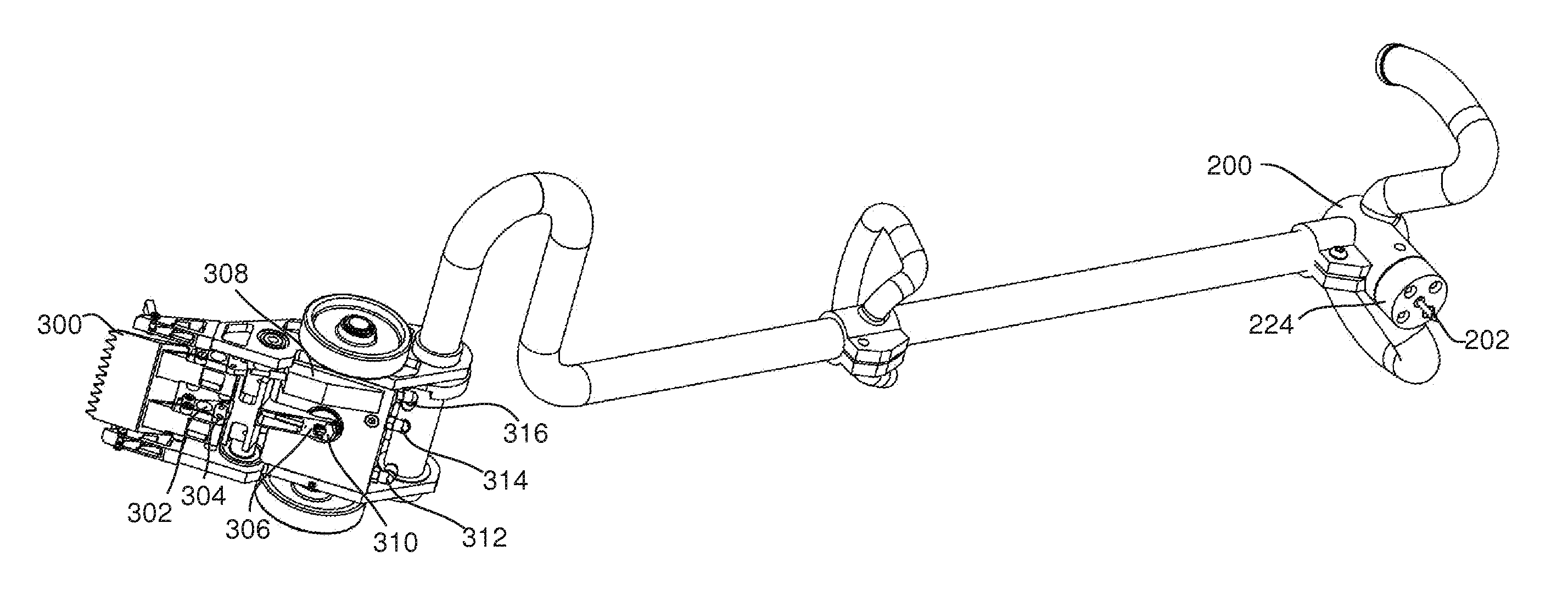

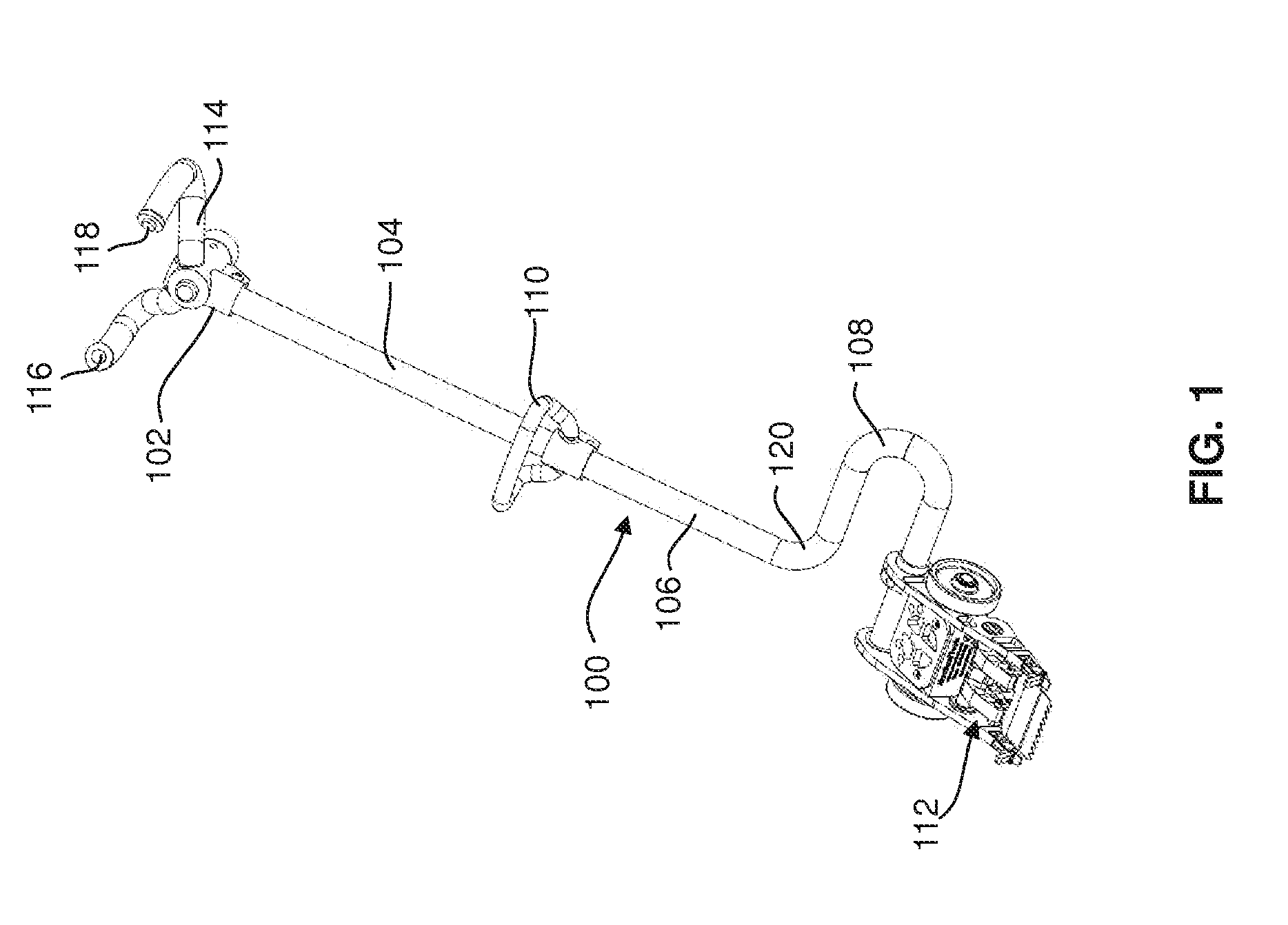

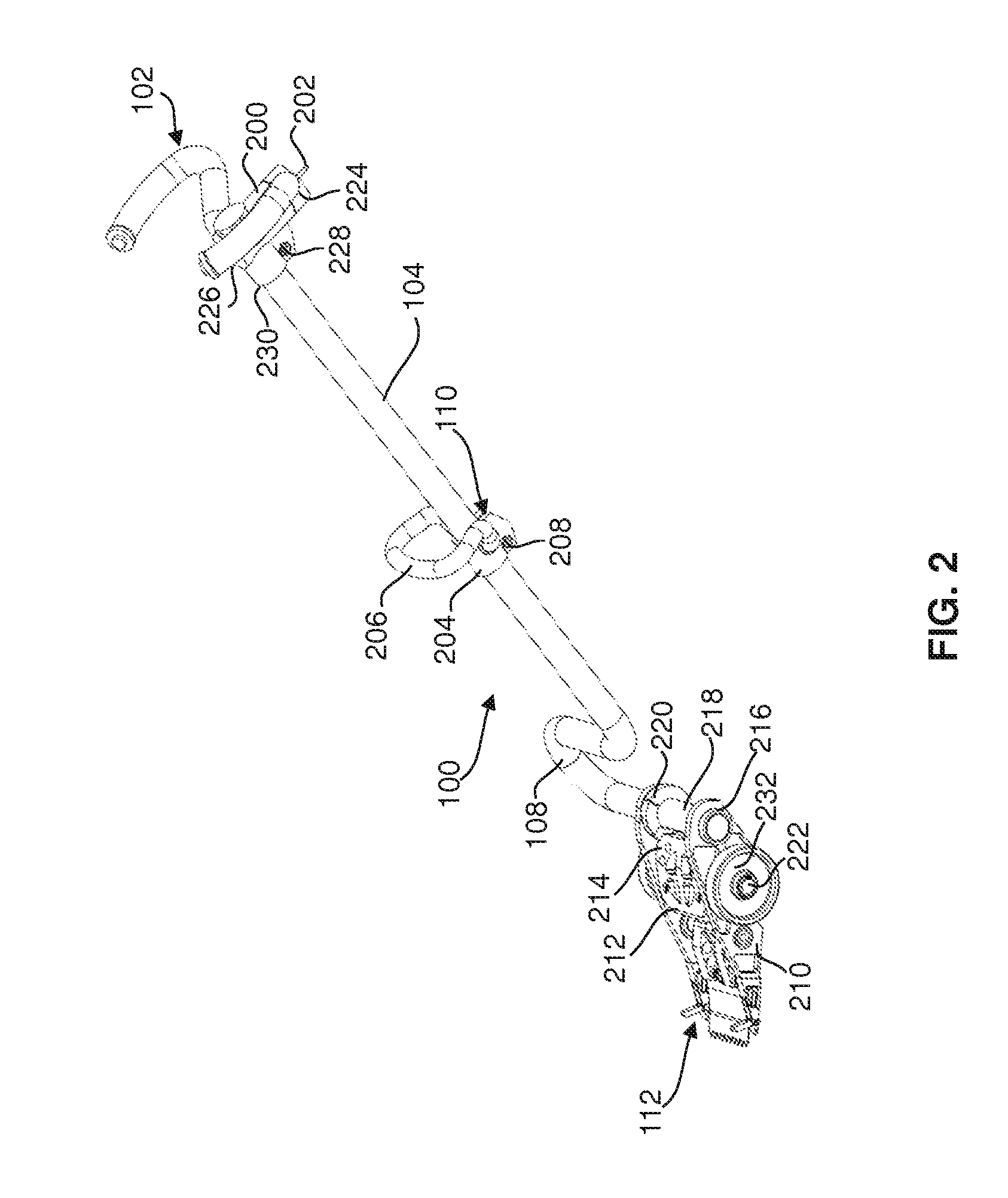

[0037]Referring initially to FIGS. 1 and 2, an exemplary embodiment of a device for removing a surface covering material from a substrate is shown. The device is referred to as a powered shingle remover 100. The remover 100 comprises a handle assembly 102 connected to a housing referred to as operating head 112. The handle assembly 102 includes an elongate shaft 104 with a linear, straight, section 106 terminating in a curved section 108. The linear section 106 of the shaft transitions into the curved section 108 through a plurality of elbows 120 to define a generally “C” shape lying in a transverse plane. Situated on the linear straight section 106 is a stabilising handle 110, whose position may be adjusted along the linear section 106 to suit the operator using the remover 100.

[0038]The handle assembly 102 terminates in a yoke 114 for primary control by the operator. A plurality of switches are located on the yoke 114 for access by the operator including a switch 116 for manual ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com