Thin film composite hollow fiber membranes for osmotic power generation

a technology of osmotic power generation and thin film composite, which is applied in the direction of membranes, filtration separation, separation processes, etc., can solve the problems of adversely affecting the pwp rate, and achieve the effect of high water permeability rate and high pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Hollow Fiber PES Supports

[0030]Three hollow fiber supports made of PES, designated as L, MM, and N, were prepared using a triple orifice spinneret as described below.

[0031]A spinning dope containing PES, NMP and, optionally, PEG and water, was first prepared. Listed in Table 1 below are the detailed spinning conditions for preparing these three supports and the parameters of the triple orifice spinneret. Supports L, MM, and N were prepared from different spinning dopes, each of which was made using PES of the same wt %, water of increasing wt % (0.0 to 6.4 wt %), and both PEG and NMP of decreasing wt %. See Table 1, row 3 “Spinning dope composition.” Each of the supports was prepared by extruding NMP through the external orifice of the spinneret to promote high porosity at the outer surface of the support, extruding the spinning dope through the middle orifice, and extruding water, an internal coagulant, through the internal orifice to promote formation of an inner sk...

example 2

Characterization of the Hollow Fiber PES Supports

[0032]Field emission scanning electron microscopy (FESEM) images of support showed diverse morphologies of hollow fiber PES supports L, MM, and N prepared in Example 1. Namely, the cross sections of L, MM, and N all changed from a fully macrovoid structure to a sponge-like structure.

[0033]A study was conducted to characterize L, MM, and N and the results are summarized in Table 2 below.

TABLE 2Characteristics of the hollow fiber PES supportsHollow Fiber PES SupportsLMMNMean pore diameter (nm) 9.32 8.712.25Geometric standard 1.18 1.21 1.28variation, σMWCO34,91731,67284,630Porosity 75.0 ± 0.1 75.3 ± 0.1 74.7 ± 0.1Maximum tensile 4.57 ± 0.24 4.69 ± 0.55 5.33 ± 0.19stress (Mpa)Young's modulus (Mpa)200.44 ± 27.26212.6 ± 15.23251.28 ± 4.81Extension (%) 46.45 ± 3.8749.70 ± 5.21 70.75 ± 4.02Burst pressure (bar)17.822.021.0Estimated burst 19.019.923.9pressure (bar)

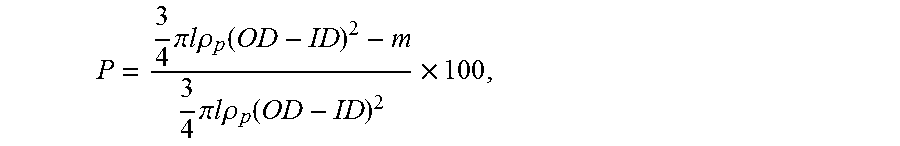

[0034]The pore size and pore size distribution of a PES support were measured b...

example 3

Preparation of TFC Hollow Fibers

[0041]A polyamide thin film layer was coated on each of the inner surfaces of PES supports L, MM, and N via the interfacial polymerization reaction between MPD and TMC. The coating was conducted as follows.

[0042]First, a tube, which had a proximal end, a distal end, and a lumen diameter the same as that of the support, was reversibly connected, at its distal end, to one end of the support. Next, an aqueous solution containing MPD 2 wt % was pumped for 3 min from the proximal end of the tube to the support to coat the inner surface of the support, followed by blowing air for 5 min from the proximal end of the tube to the support to remove excess aqueous solution. Finally, a hexane solution containing TMC 0.1 wt % was pumped from the proximal end of the tube to the support to coat the aqueous solution, thereby forming a polyamide thin film layer via interfacial polymerization between MPD and TMC on the inner surface of the support.

[0043]The TFC hollow f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com