Self-contained modular analytical cartridge and programmable reagent delivery system

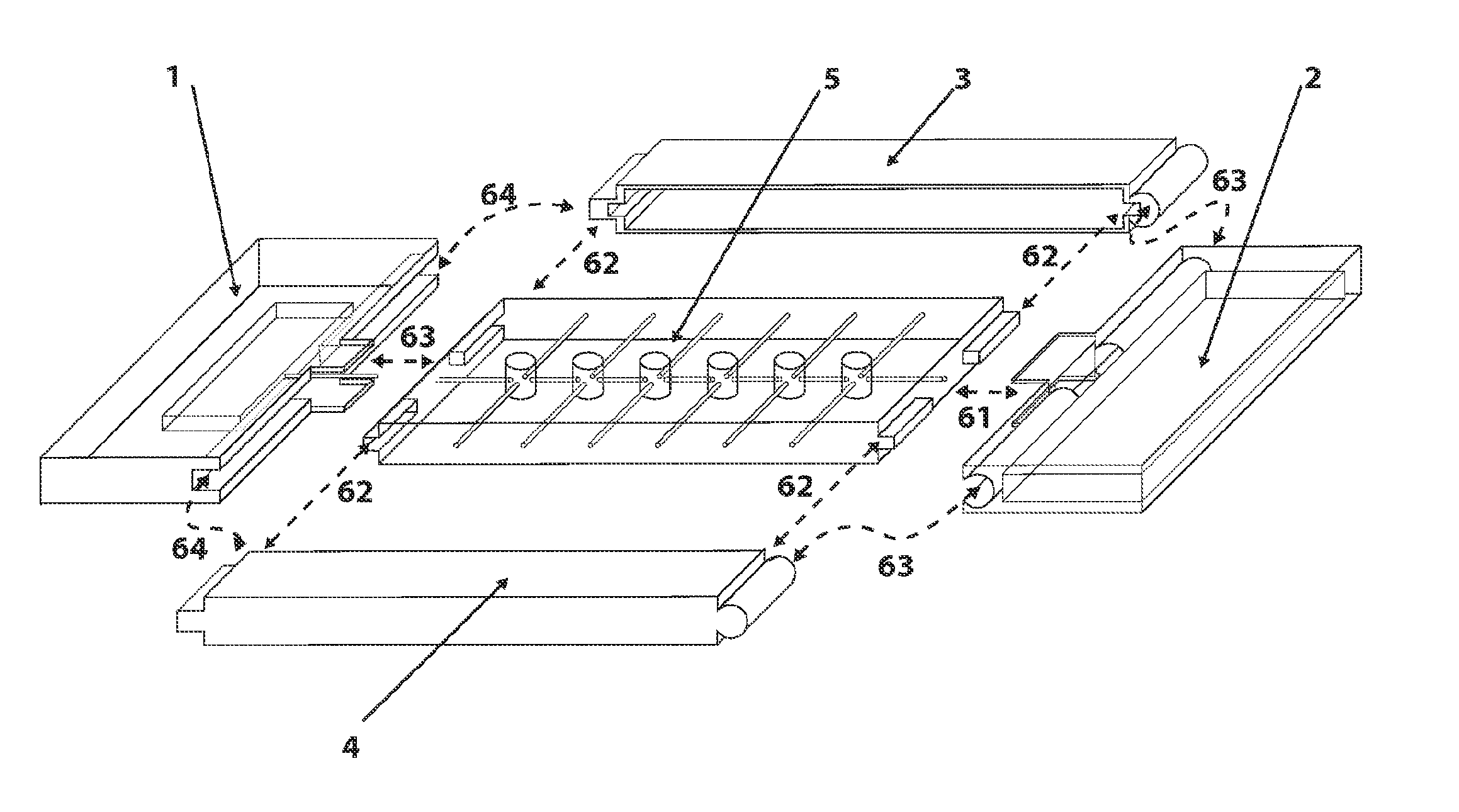

a modular, reagent technology, applied in chemical methods analysis, laboratory glassware, instruments, etc., can solve the problems of complex adaptors, different analytical instruments, and difficult design and operation of homogenous testing platforms, so as to simplify the fluid control network of devices, free up more space for more tests, and improve separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

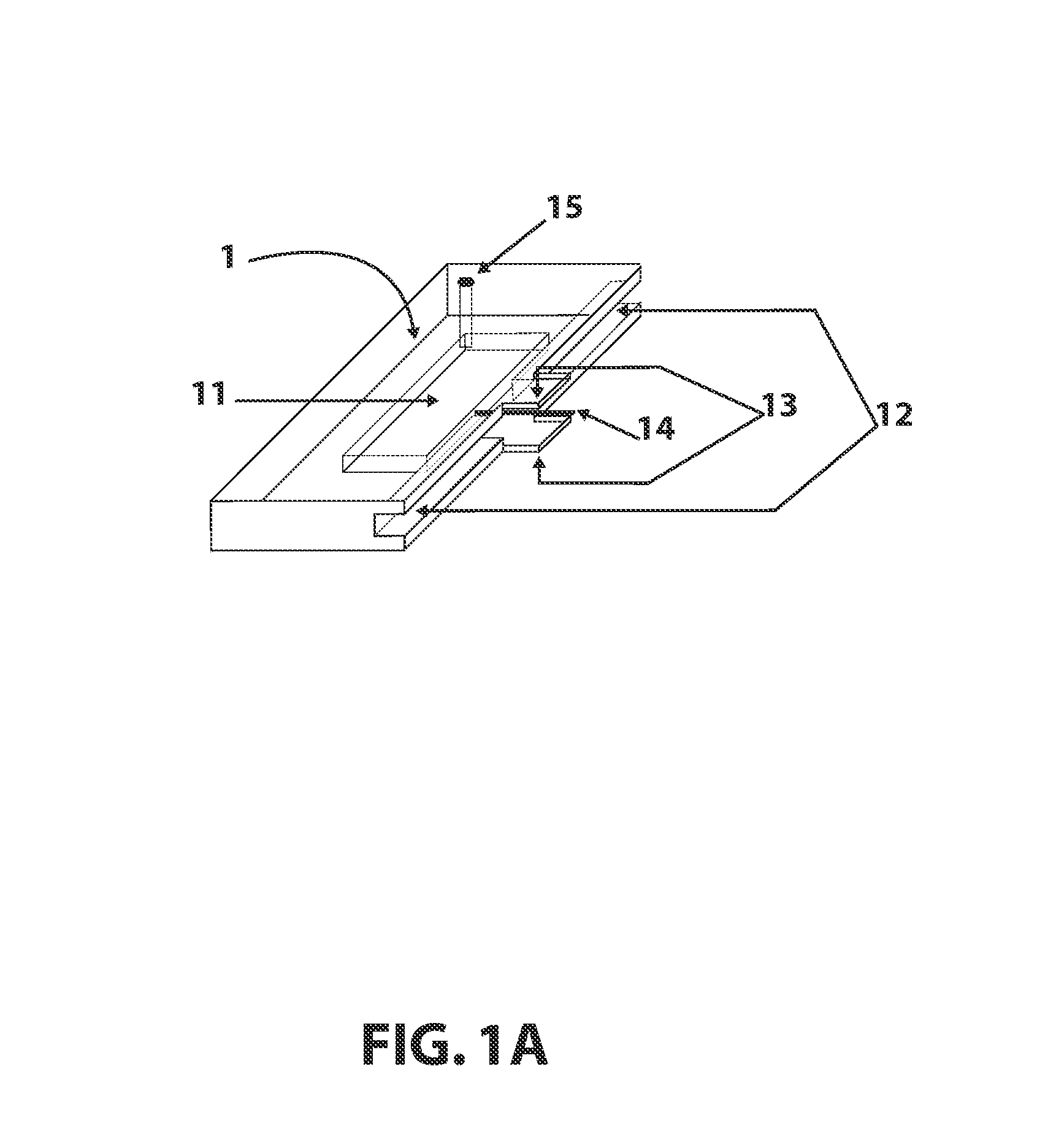

[0046]FIG. 1A Illustrates the various functional elements that might be present on a first module 1 said module comprising a sample tube 14, a port 15 and, a cavity 11 enclosed within the substrate of the module and two independent pairs of reversible mechanical attachments 12 and 13 enabled to receive mechanical attachments from two cooperating modules. Referring to the cavity 11, said cavity could be used to store a volume of fluid material; such as, used or unused analytical reagents or a sample. Said fluid material could be stored in this cavity by placing the supply tube 14 in fluid communication with a source of material and then subtracting a gas or other material from the cavity by way of the port 15. This would establish a pressure gradient spanning the cavity resulting in the fluid material being drawn into the cavity. However, other options are available and may be more preferable for a specific analytical test. For example, said cavity could be set under a vacuum (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com