Method of fabricating semiconductor structure

a technology of semiconductor structure and fabrication method, which is applied in the direction of semiconductor/solid-state device details, diodes, radio frequency controlled devices, etc., can solve the problems of low throughput, low throughput, and high complexity of the sensor fabrication process, so as to improve the light absorption efficiency of the cmos sensor, the effect of reducing costs and improving throughpu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

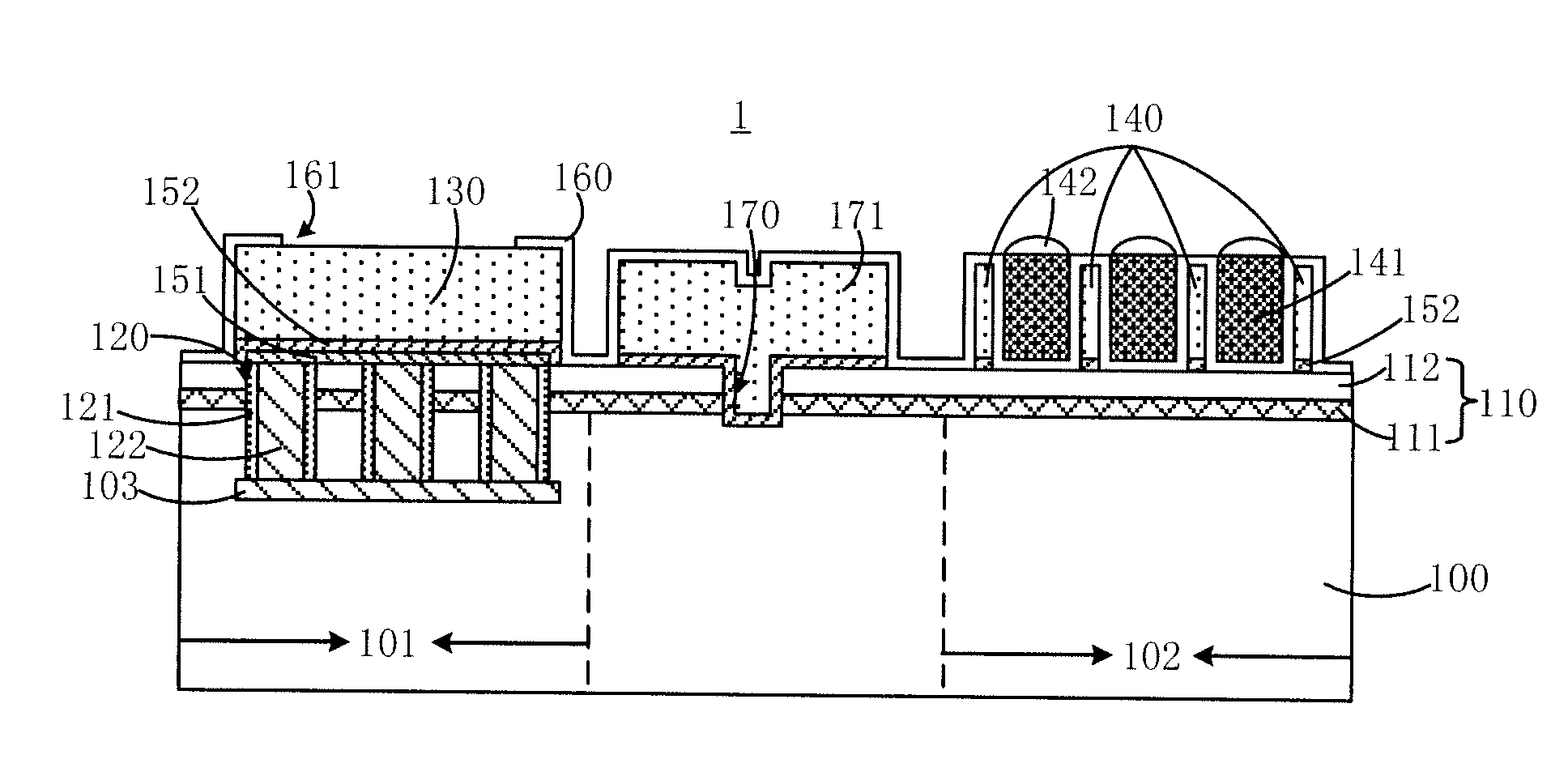

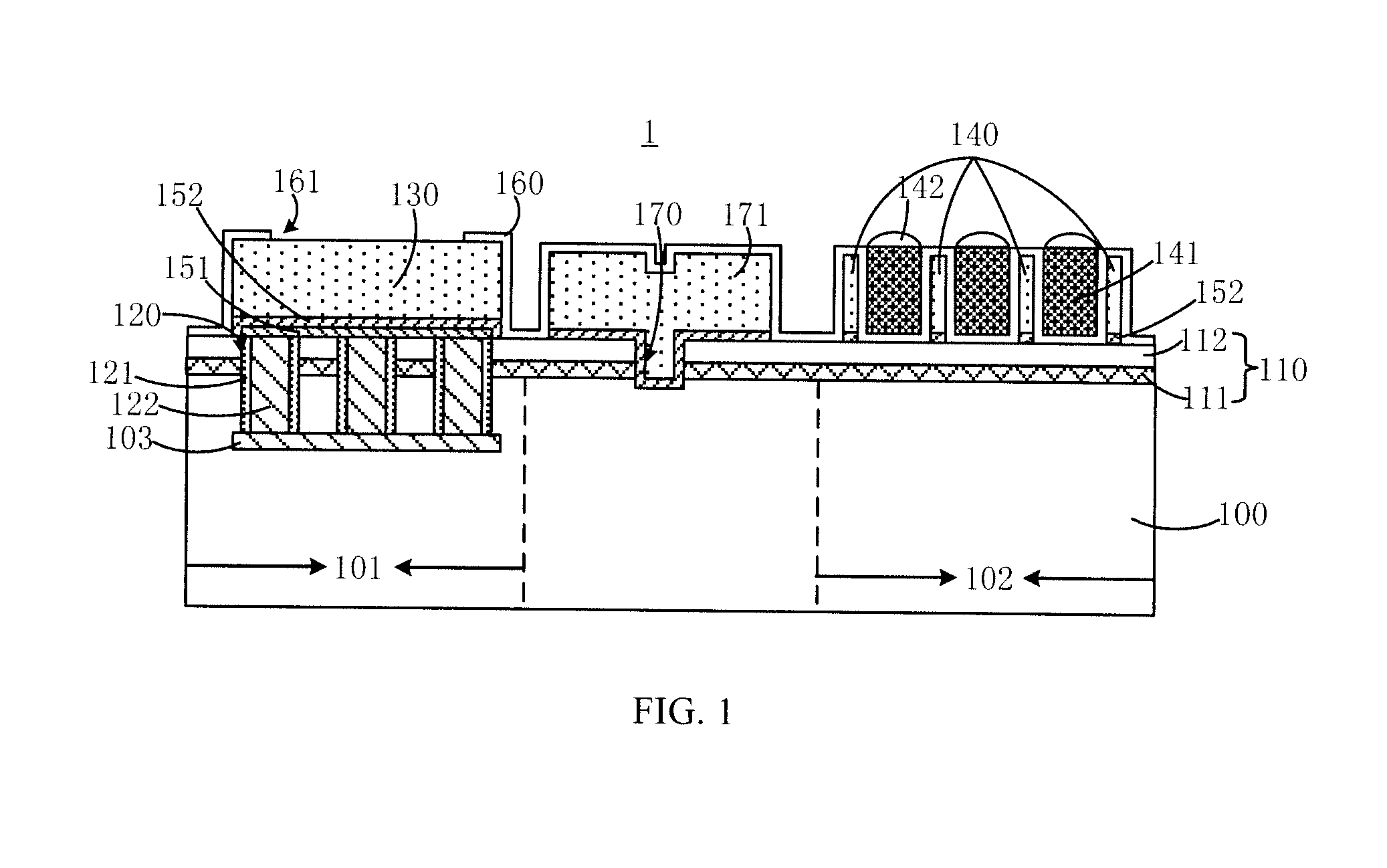

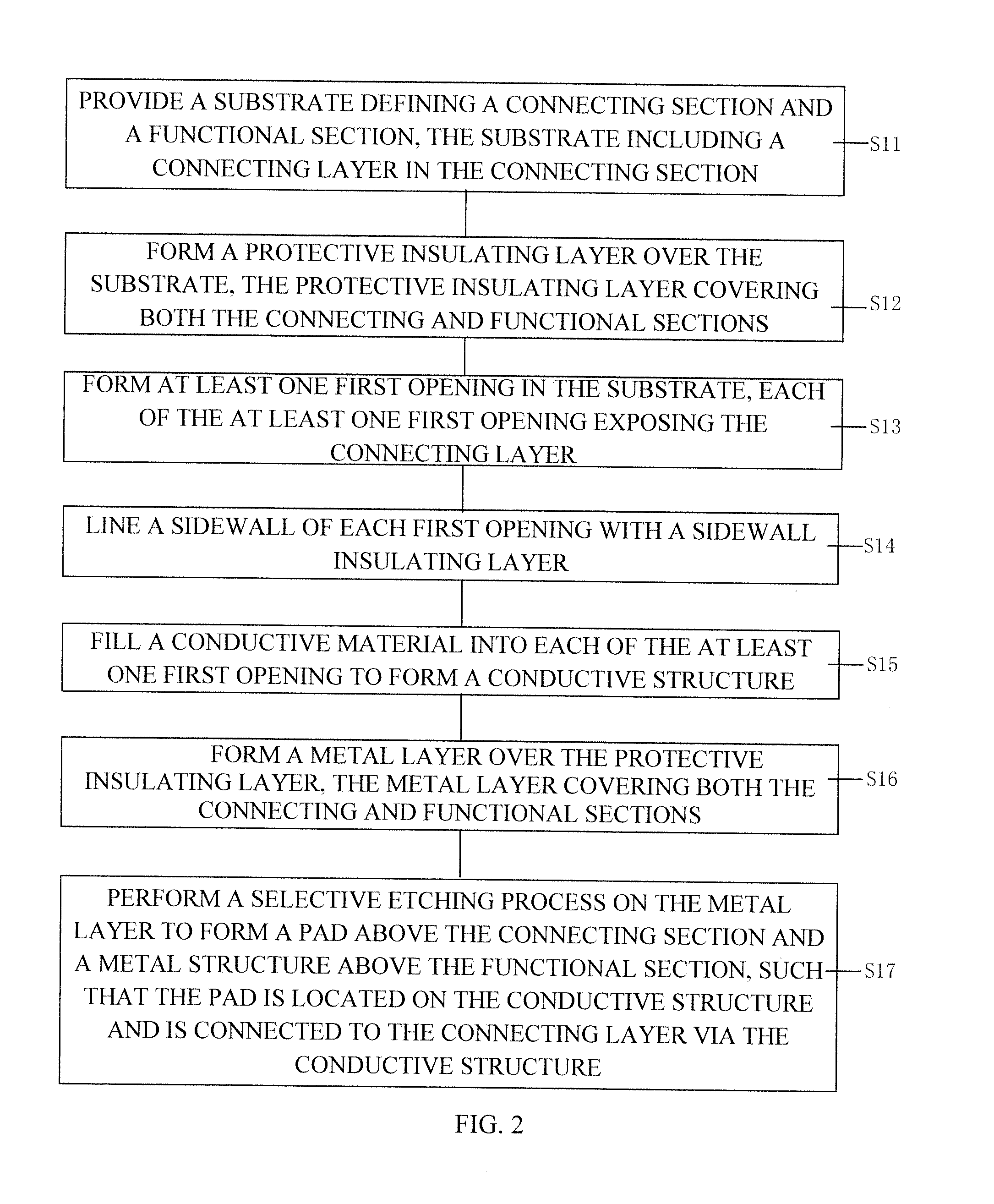

[0028]The semiconductor structure and the method of fabricating the structure, of the present invention, will be described in greater detail in the following description which demonstrates preferred embodiments of the invention, in conjunction with the accompanying drawings. Those of skill in the art should, in light of the present disclosure, appreciate that many changes can be made in the specific embodiments disclosed herein and still obtain the same beneficial results. Therefore, the following description should be construed as the illustrative of the principles of the present invention, and not providing limitations thereto.

[0029]For simplicity and clarity of illustration, not all features of the specific embodiments are described. Additionally, descriptions and details of well-known functions and structures are omitted to avoid unnecessarily obscuring the invention. The development of any specific embodiment of the present invention includes specific decisions made to achieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com