Drill rig and methods for directional drilling

a drilling rig and directional drilling technology, applied in the field of civil engineering, can solve the problems of unsuitable above-mentioned methods, the device cannot be protected from shocks and vibrations transmitted by the drill, etc., and achieve the effect of speeding up directional drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

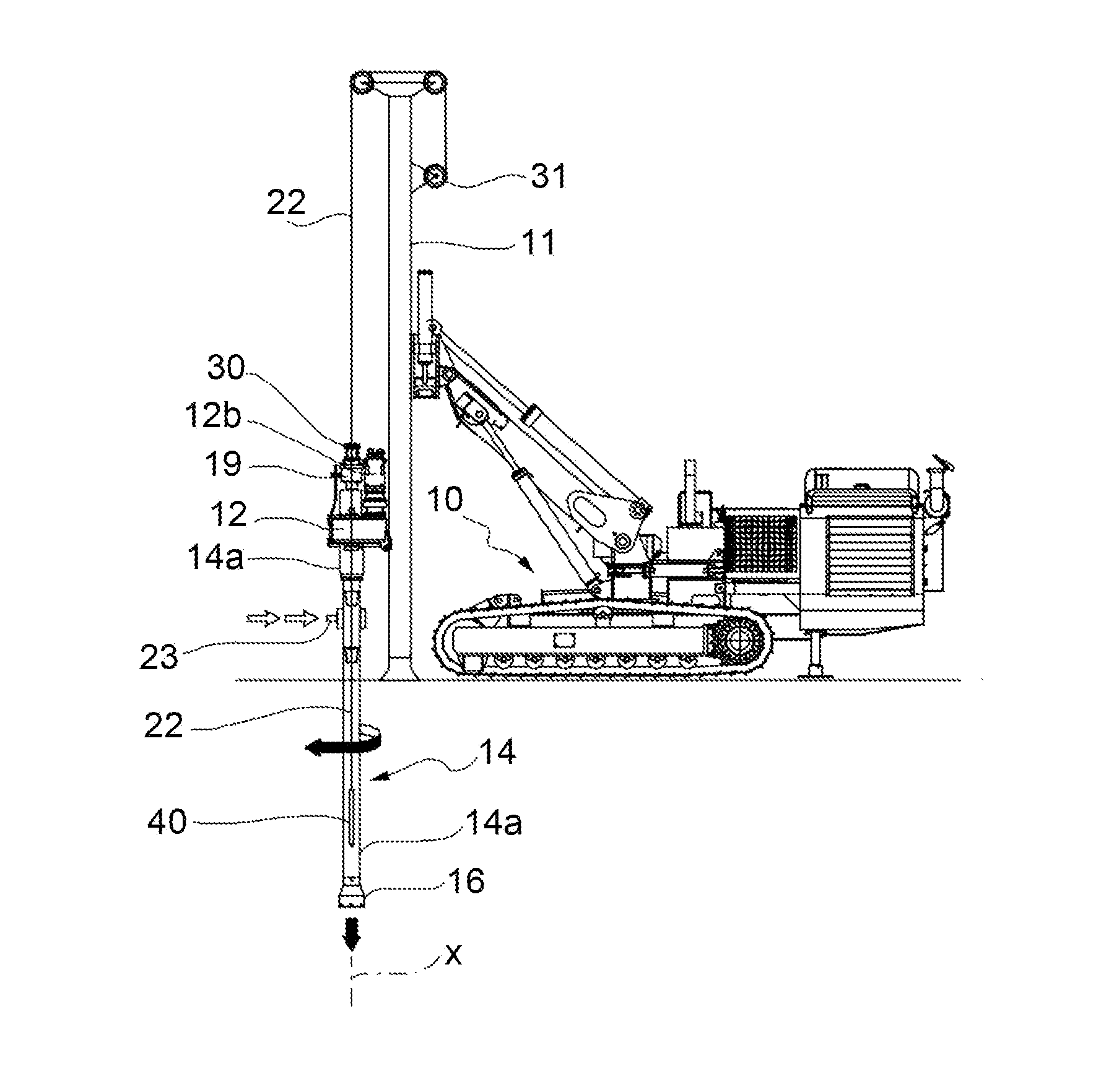

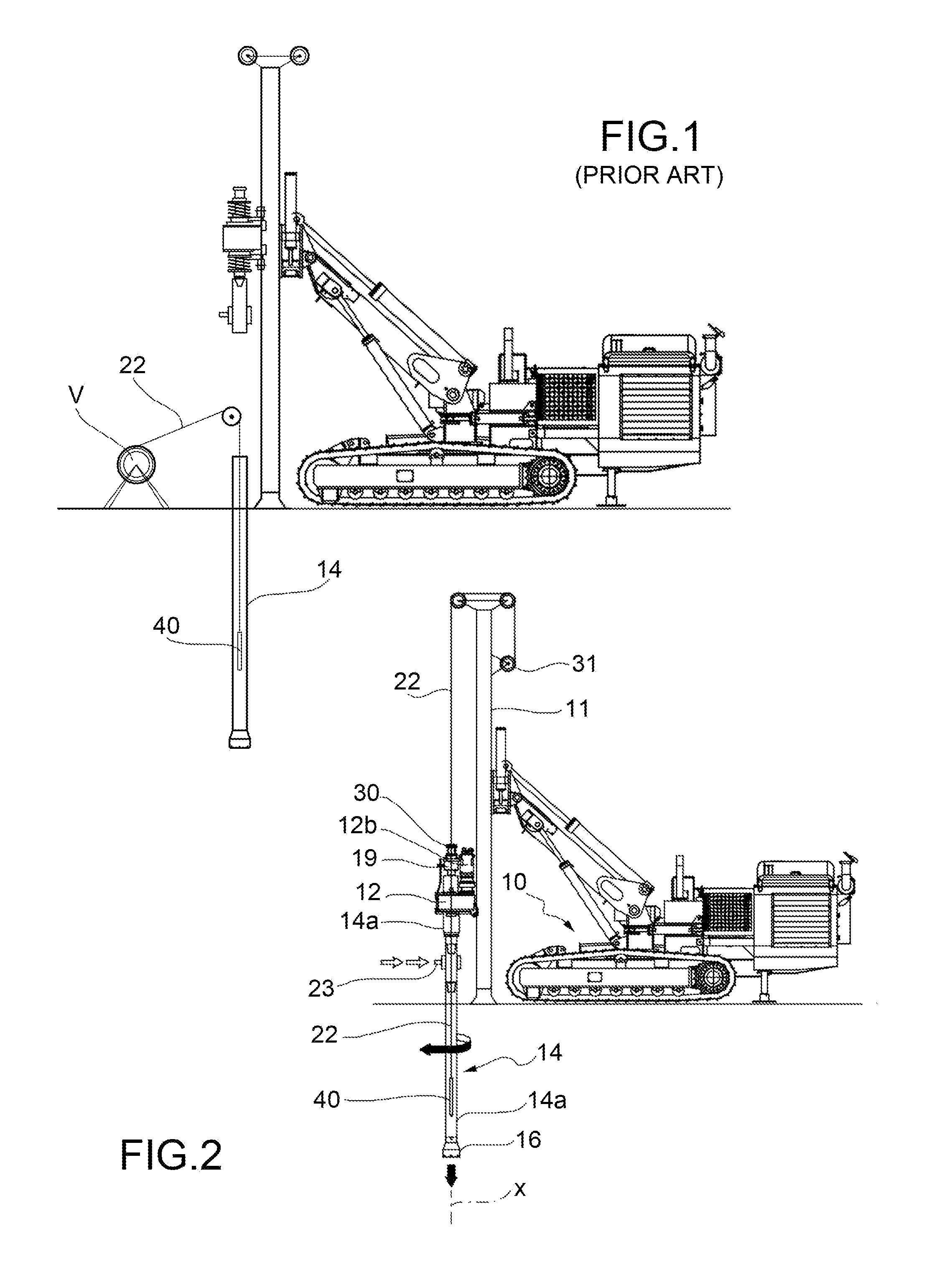

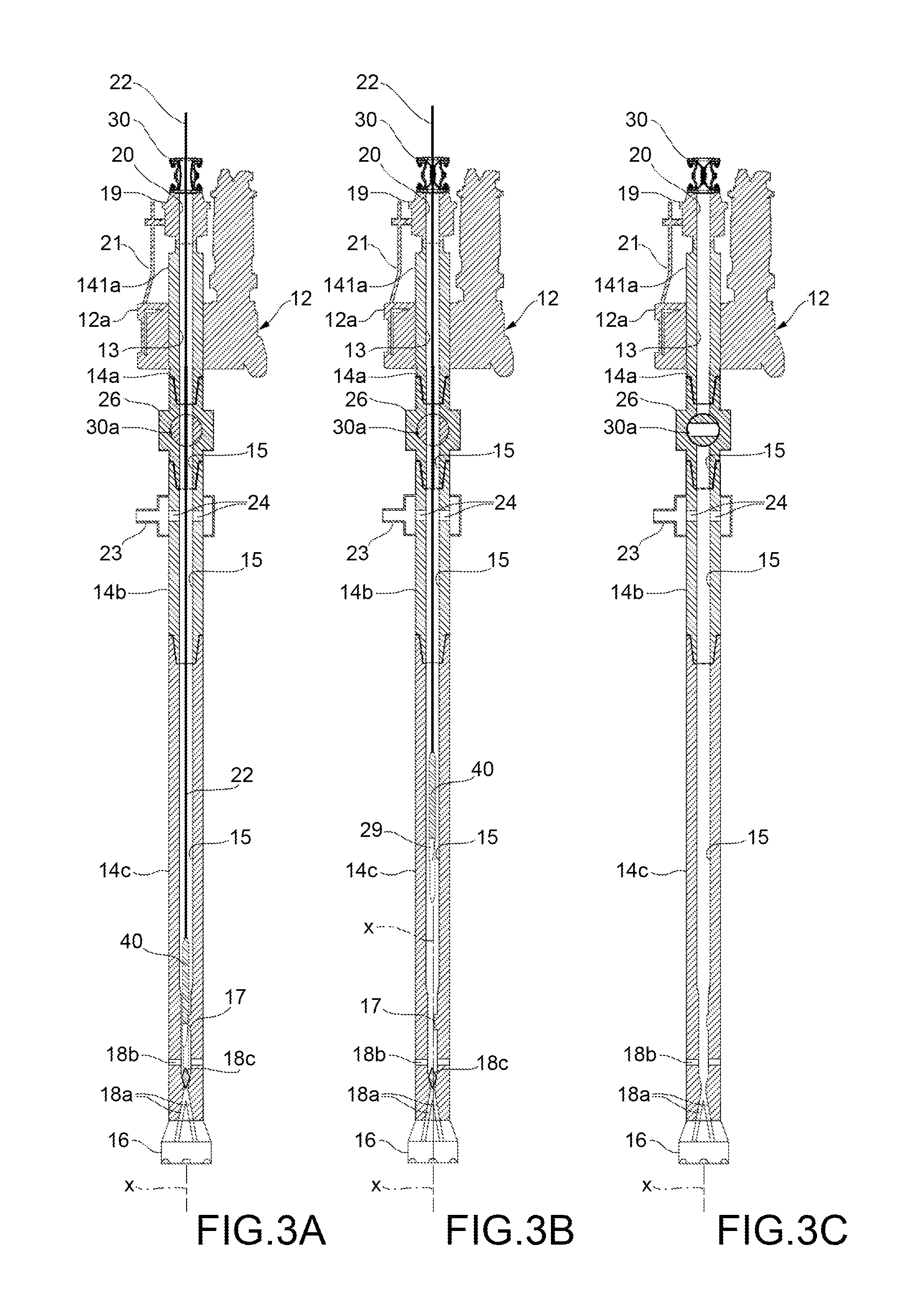

[0022]Referring to FIG. 2, a self-propelled vehicle 10 carries a drilling mast 11, in this example illustrated in an upright or vertical position. Slidably mounted along the mast 11 is a top-drive rotary head 12. The rotary head serves to impart rotation and sliding movement (push-pull) to a string 14 of hollow rods for carrying out soil perforation or drilling. The rotary head may be driven by an associated hydraulic motor gear 12b. A boring tool 16 is fixed at the bottom end of the string 14 of rods.

[0023]The general structure of a drilling mast and of the actuating means of a rotary head are to be considered generally known. Consequently, the present description will describe in detail only those elements of specific importance and interest for the purposes of implementing of the invention. For the construction of the parts and elements not shown in detail, such as the motor assembly for driving the rotary head and the drive systems of the boring tool, reference may be made to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com