Electric current sensing and management system for electrolytic plants

a technology of electrolytic plants and current sensing, applied in the field of metalurgical systems, can solve the problems of reducing system efficiency, short circuits, and reducing current and power efficiency, and achieve the effects of improving one or more of the functions, adaptability, control and human-interface, and improving the behaviour of the electrolytic cell and/or tankhous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

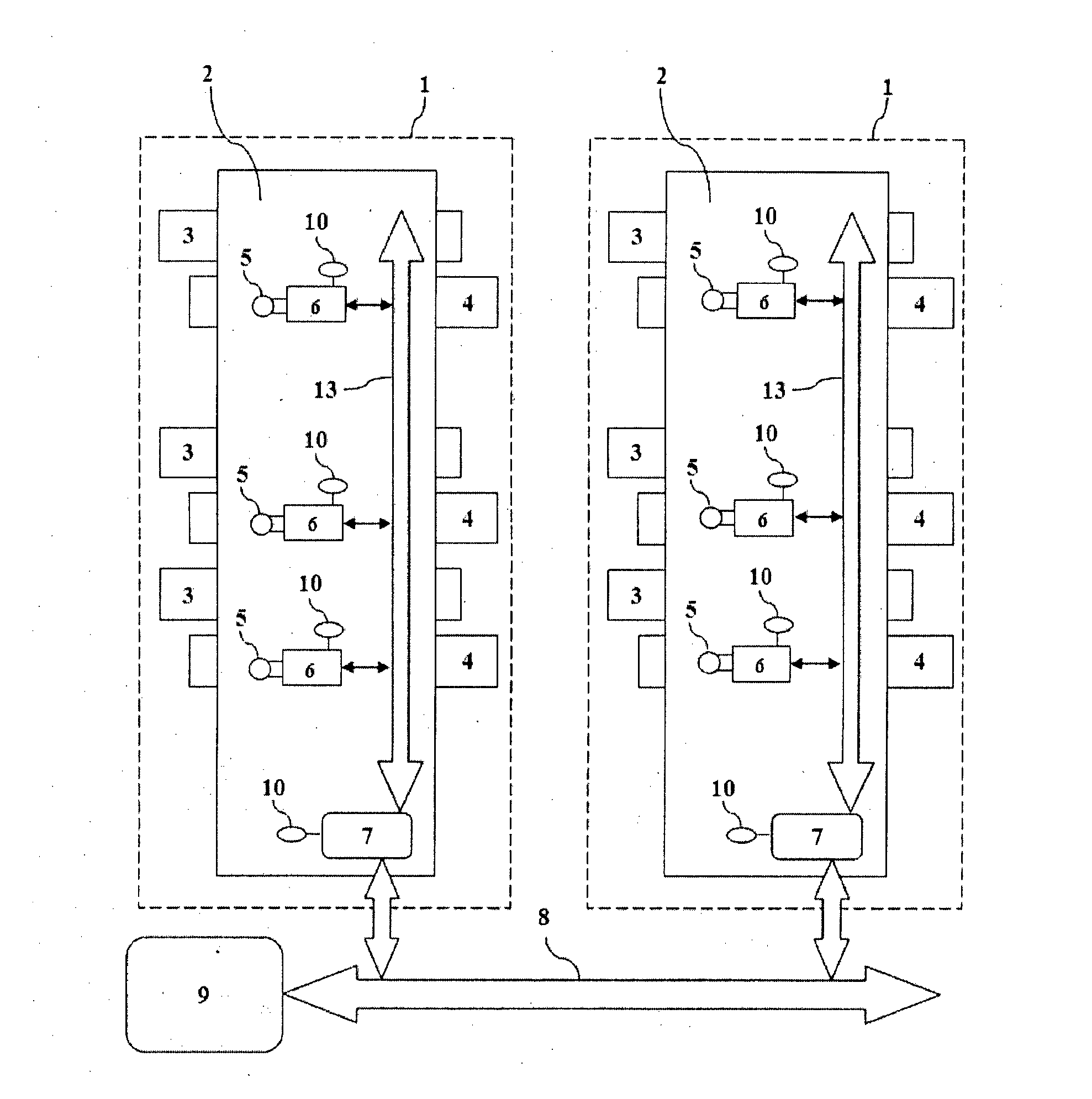

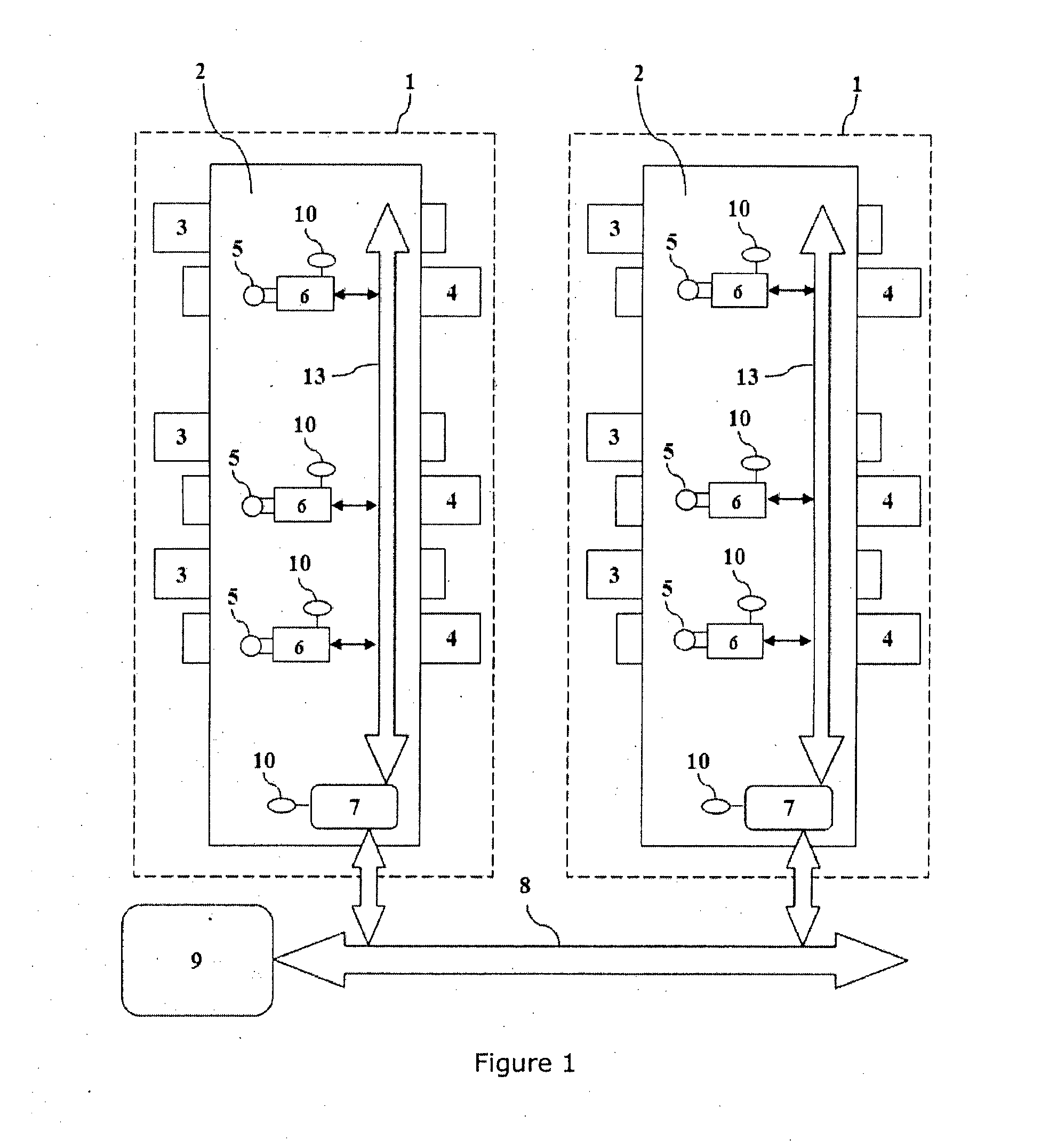

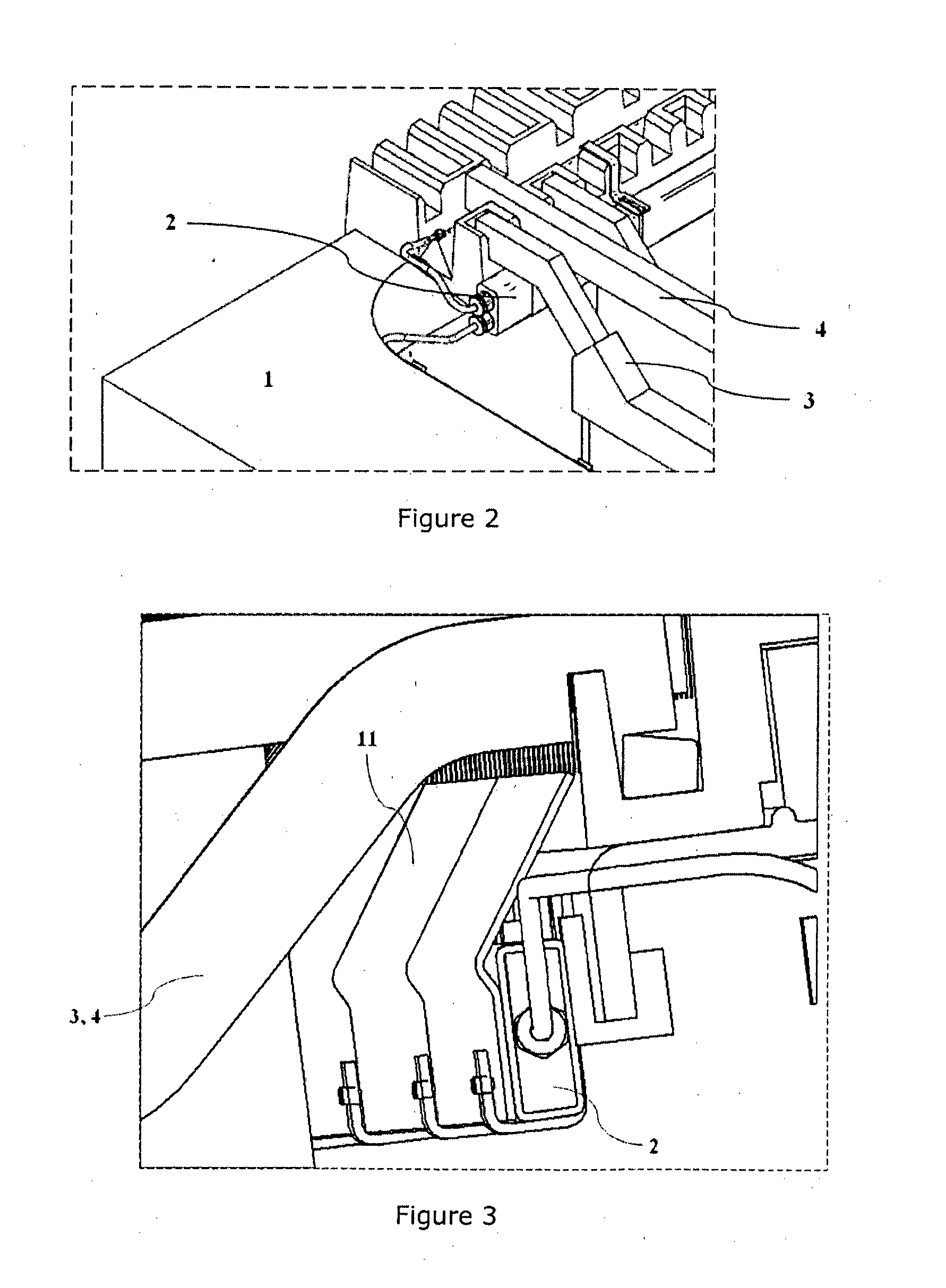

[0059]As shown in FIG. 1, an embodiment of the invention comprises an electrolysis cell (1) comprising a plurality of cathodes (4) and anodes (3) within an electrolyte media, arranged in an alternating manner relative to each other. In the case of the invention, cathodes (4) and anodes (3) correspond to plates which are arranged parallel to each other. In the vicinity of each plate, preferably, of each one of the cathode plates, sensor means (5) are arranged on a sensor bar (2) or ECM bar. Such sensor bar, that is part of the ECM system of the invention, is located in the vicinity of the current bar output (or input) from (or to) the cathode (or anode) plate. Such sensor bar and such sensor means need not be in direct contact with the electrodes. Additionally, the ECM bar (2) may be located in one of many places of the electrolytic cell (1) such as within cell wall, within cell (as shown in FIGS. 2 to 10), within cell top furniture / insulators, attached to electrodes or others. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field | aaaaa | aaaaa |

| Electric charge | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com