Pushup Jeans and Related Production Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

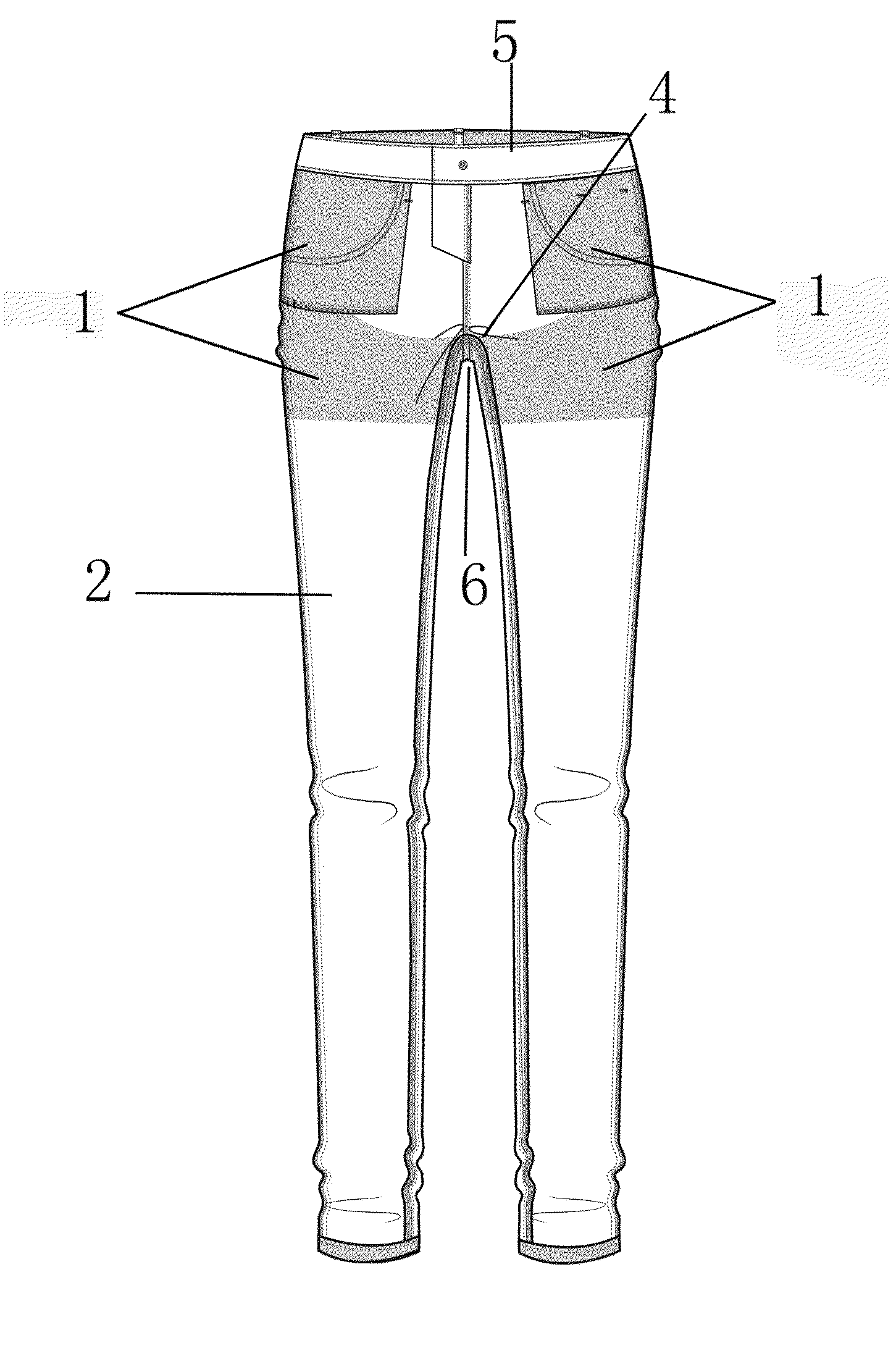

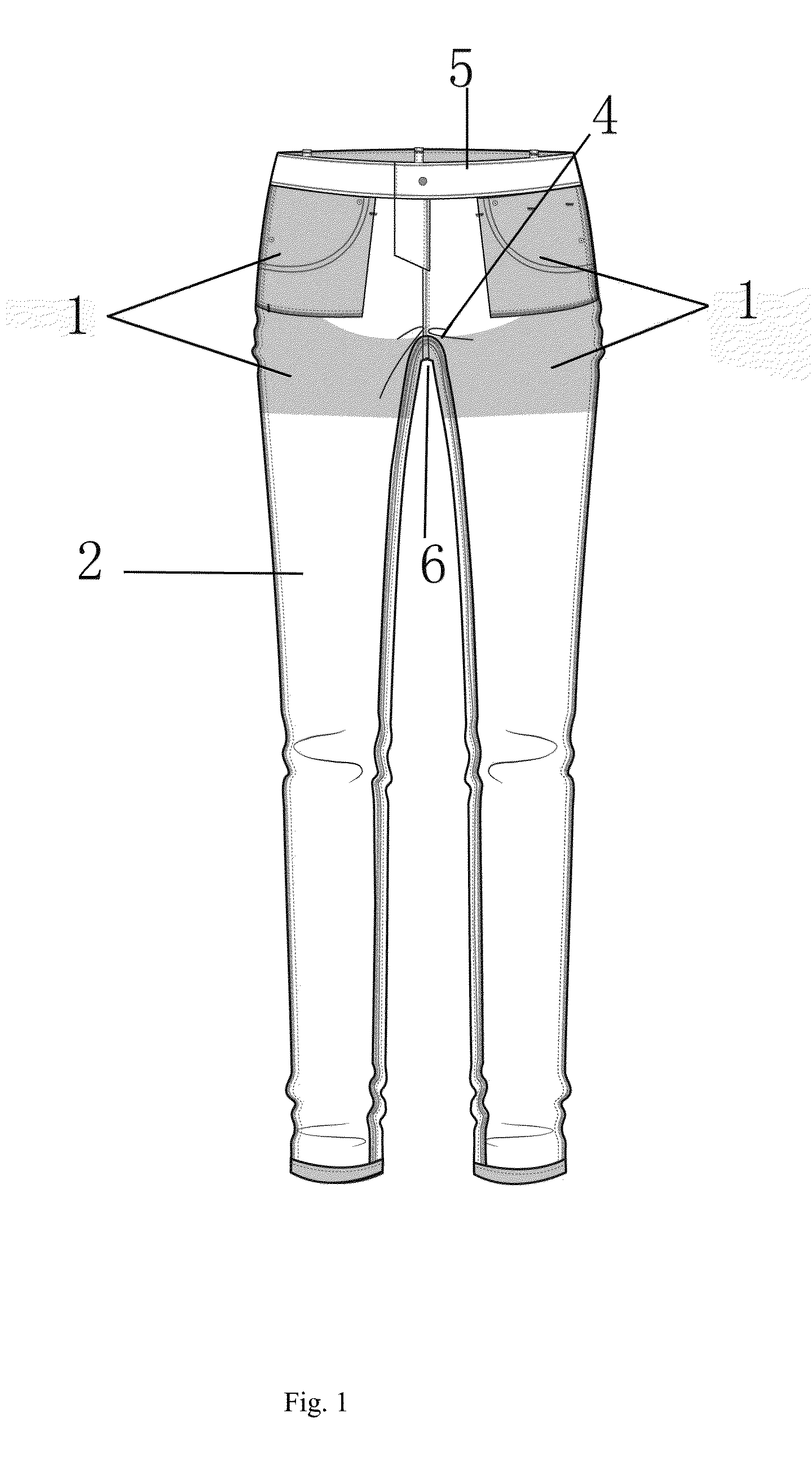

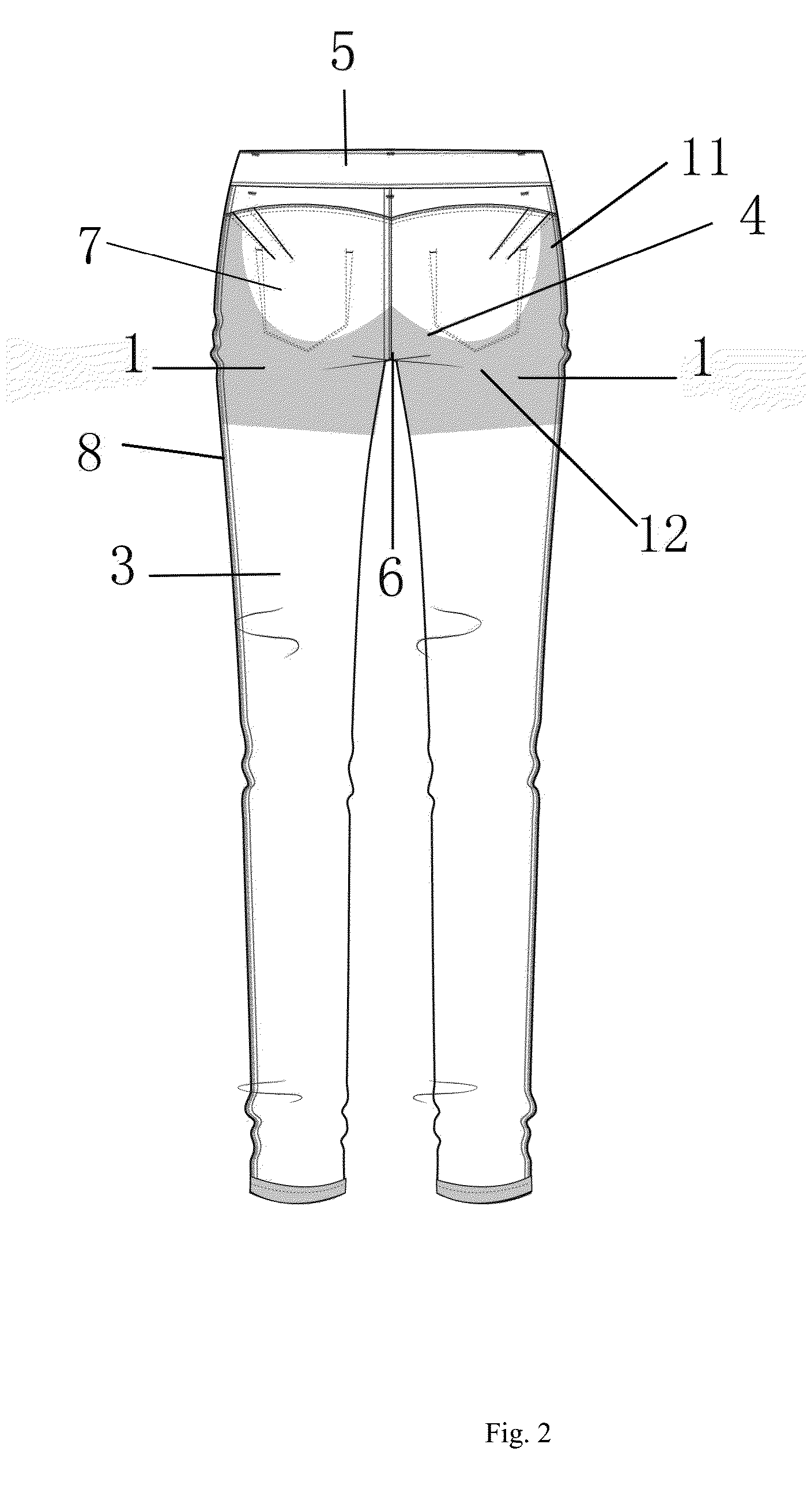

[0022]In the following the invention will be further described in connection with the drawings.

[0023]As shown in FIG. 1, pushup jeans comprises jeans and a fusible interlining 1, each pant leg comprises a front panel 2 and a back panel 3, the fusible interlining 1 is being disposed on the back panel 3 and adhered to the bottom 11 and outside 12 of the hips 7; at the same time, a fusible interlining 1 is disposed on inside of front panel 2 and opposite to the fusible interlining 1 of the back panel 3; the fusible interlining 1 has an arc-shaped portion 4, and the arc-shaped portion 4 is recessed downwards. The structure of the fusible interlining 1 designed by the invention is kept away from the positions of the hips 7, such that the hips areas 7 are in elastic fabric, and whole hips 7 will become more rounded. The fusible interlining is used to reduce the elasticity on all around and bottom 11 of hips 7. The outer edges of the fusible interlining 1 are aligned with the outer edges o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com