Exterior member manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

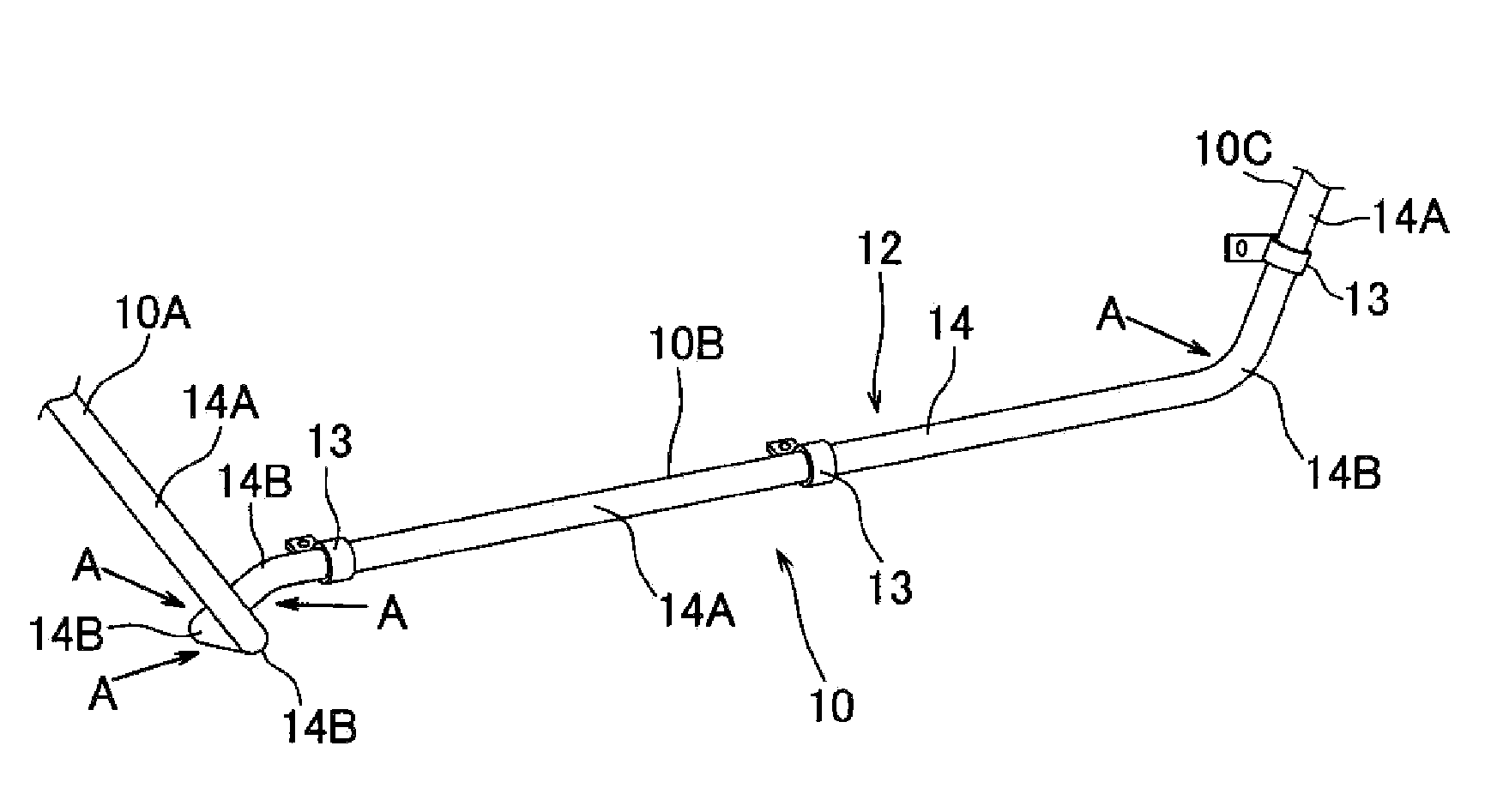

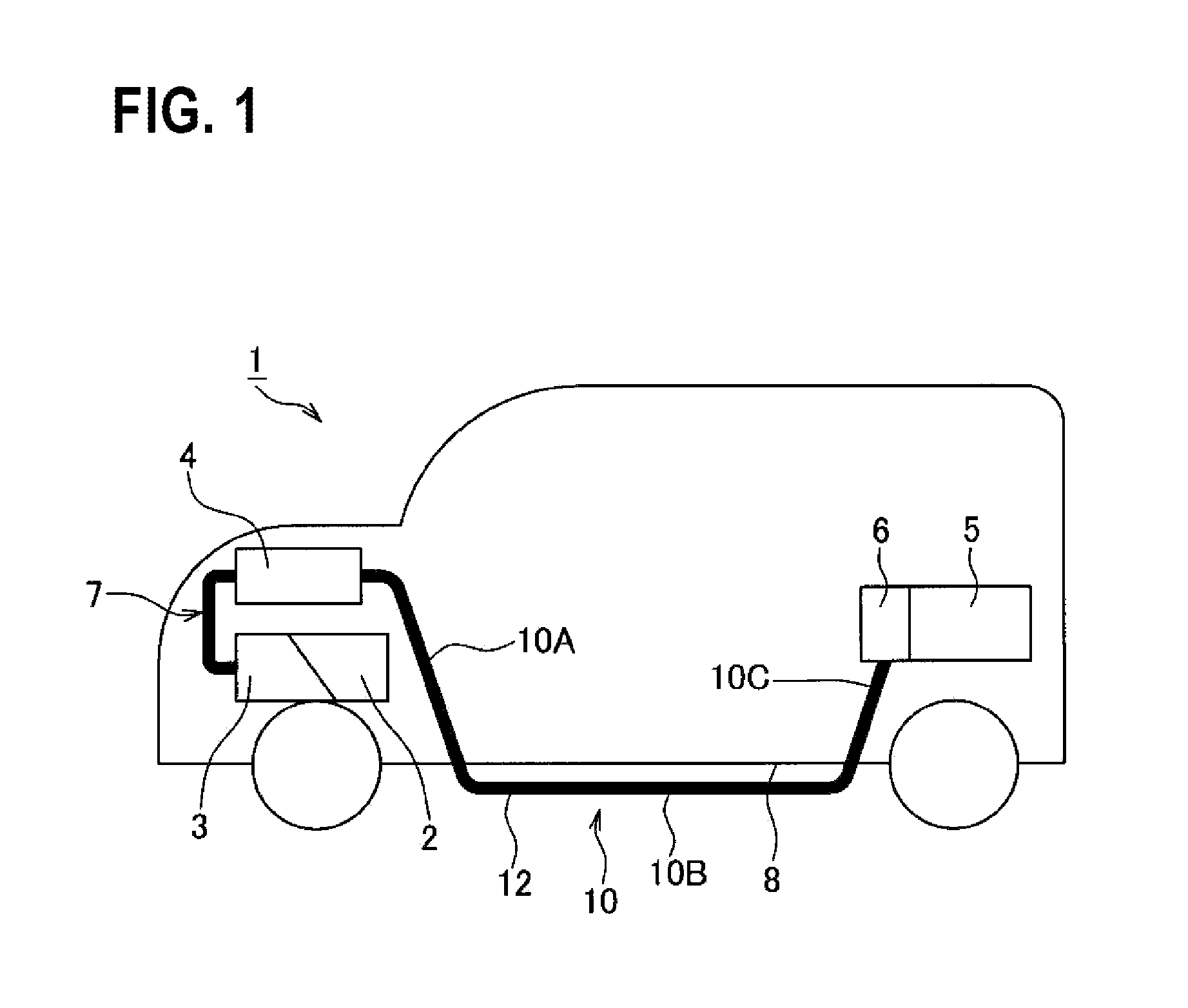

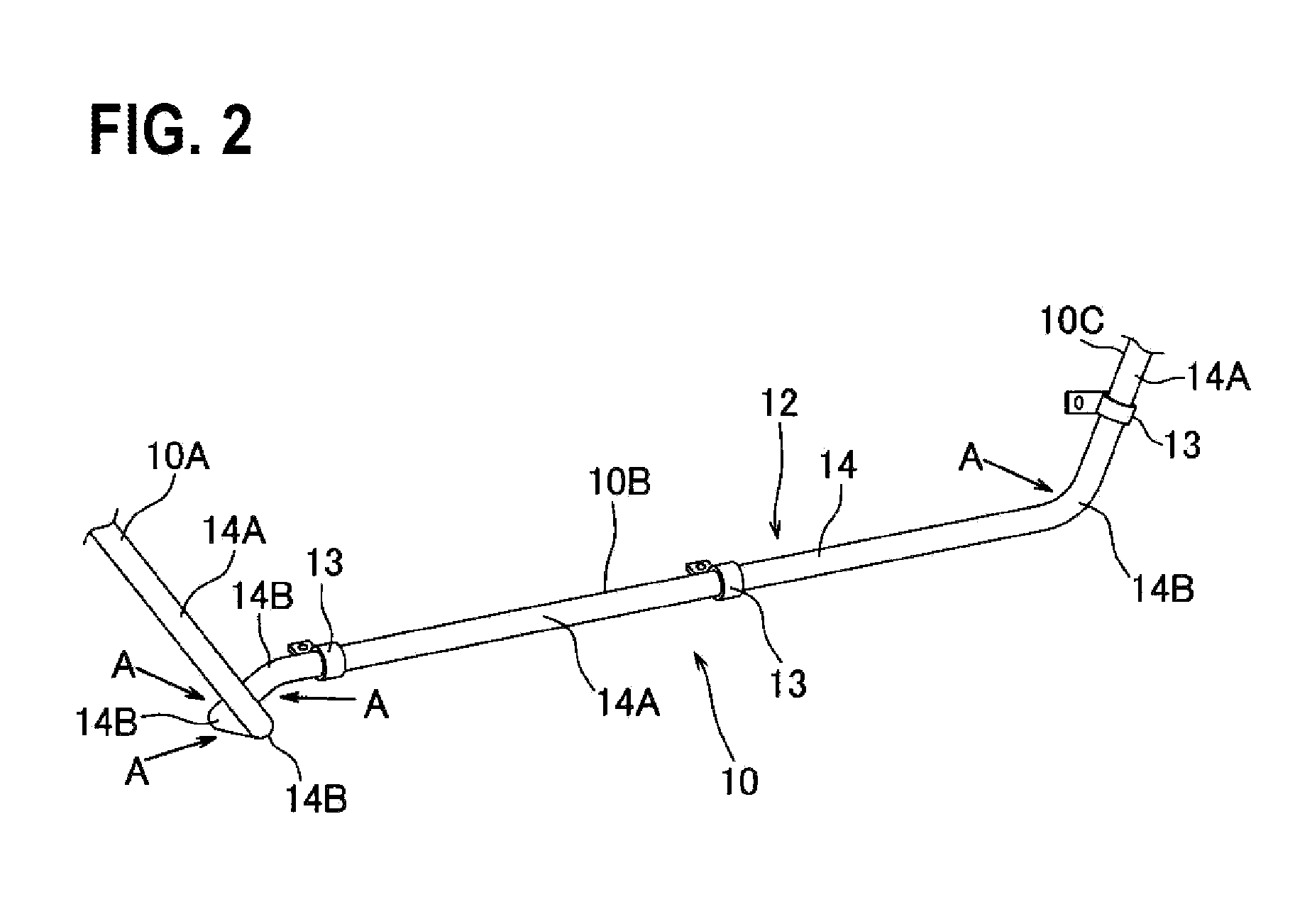

[0023]An electric wire wiring structure and an exterior member 20 which is used in the electric wire wiring structure according to an embodiment of the present invention are described by using FIGS. 1 to 4B. In the embodiment, an automobile (namely, vehicle) 1, especially a hybrid vehicle which is driven with the driving force of both an engine and an electric motor, is illustrated, and an electric wire wiring structure 10, which the automobile 1 is provided with, is described. In addition, the automobile 1 is not limited to a hybrid vehicle, but also may be an electric vehicle which is driven by the driving power from an electric motor.

[0024]The automobile 1 includes an engine 2 and an electric motor 3 which are loaded in the engine room at the front of the automobile, an inverter 4 which is provided near the electric motor 3, a battery 5 which is loaded below the trunk room or a seat at the rear of the automobile, and a junction block 6 which is electrically connected to the batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com