Processes and systems for discharging amine byproducts formed in an amine-based solvent

a technology of amine-based solvent and process, which is applied in the direction of biological water/sewage treatment, separation processes, water/sewage treatment by degassing, etc., can solve the problems of environmental objection and cost of discharging hazardous waste of contaminated amine-based solven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]The following Detailed Description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding Description of Related Art or the following Detailed Description.

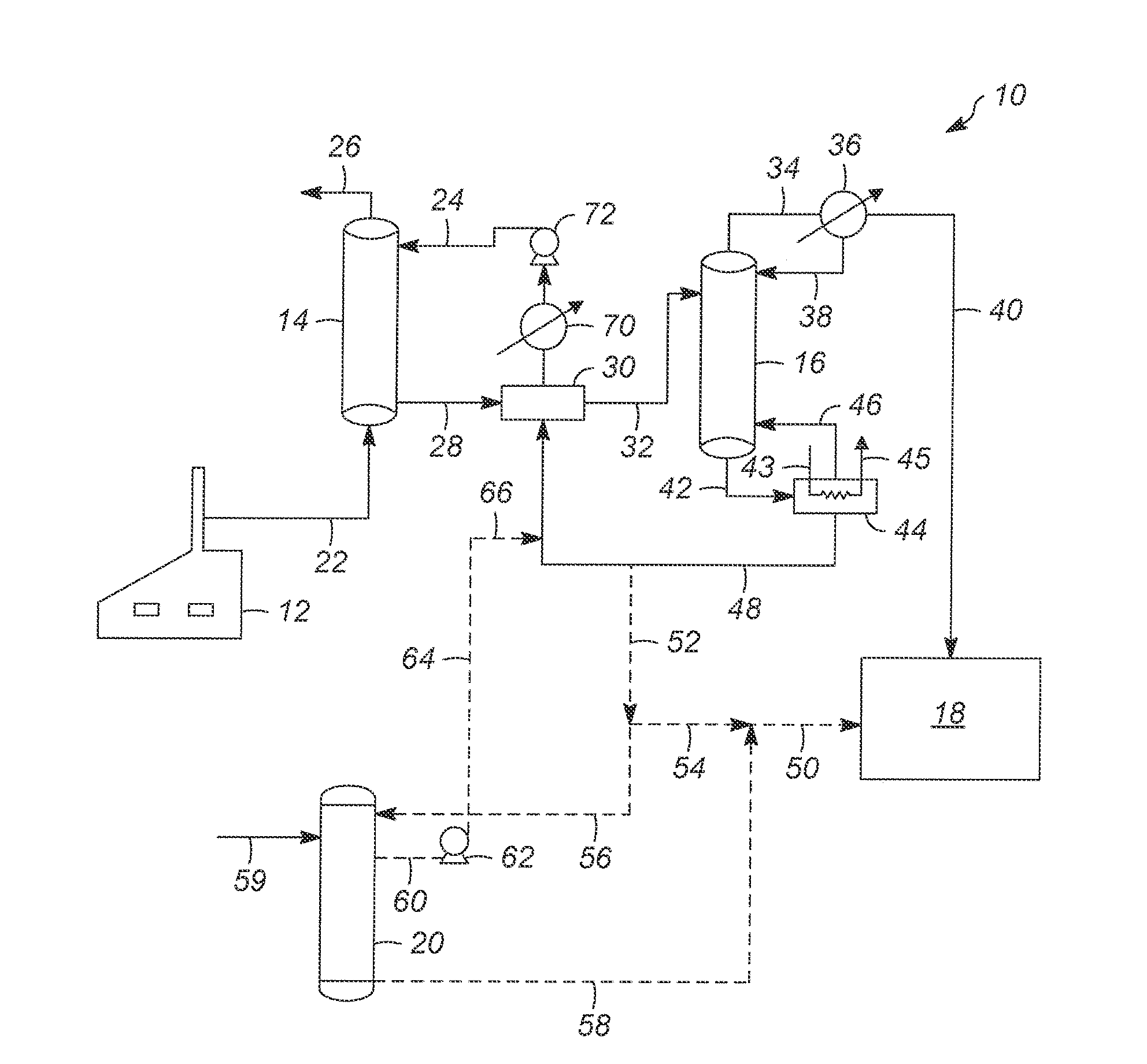

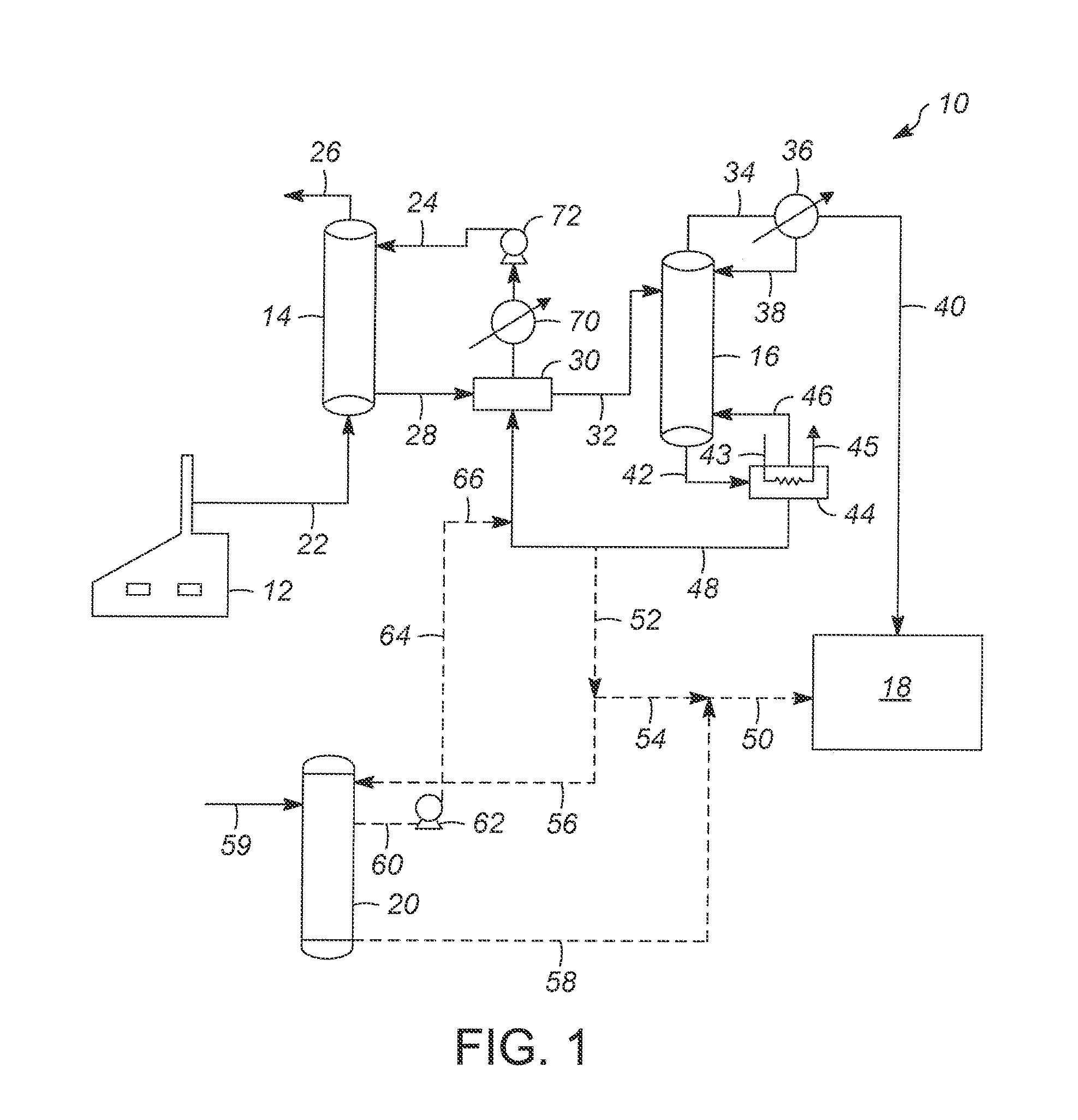

[0011]Various embodiments contemplated herein relate to processes and systems for discharging amine byproducts formed in an amine-based solvent that is used for absorbing carbon dioxide from flue gas. In a carbon dioxide absorber unit, the amine-based solvent is contacted with flue gas that typically comprises carbon dioxide, oxygen, nitrogen, nitrous oxides (NOx), sulfur oxides (SOx), and other gaseous components and particulates. The amine-based solvent readily absorbs the carbon dioxide as well as some of the other gaseous components of the flue gas. However, over time and continuous recycling through the carbon dioxide absorber unit and a carbon dioxide stripper unit that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com