Refrigerating capacity control device, a testing apparatus and a refrigerating control method using the device

a technology of refrigerating capacity and control device, which is applied in the direction of cooling fluid circulation, domestic cooling apparatus, lighting and heating apparatus, etc., can solve the problems of difficult application of this technology in general purpose appliances and equipment, difficulty in optimizing refrigerating capacity and precise temperature control of electronic expansion valve as throttling device, etc., and achieves the effect of low control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

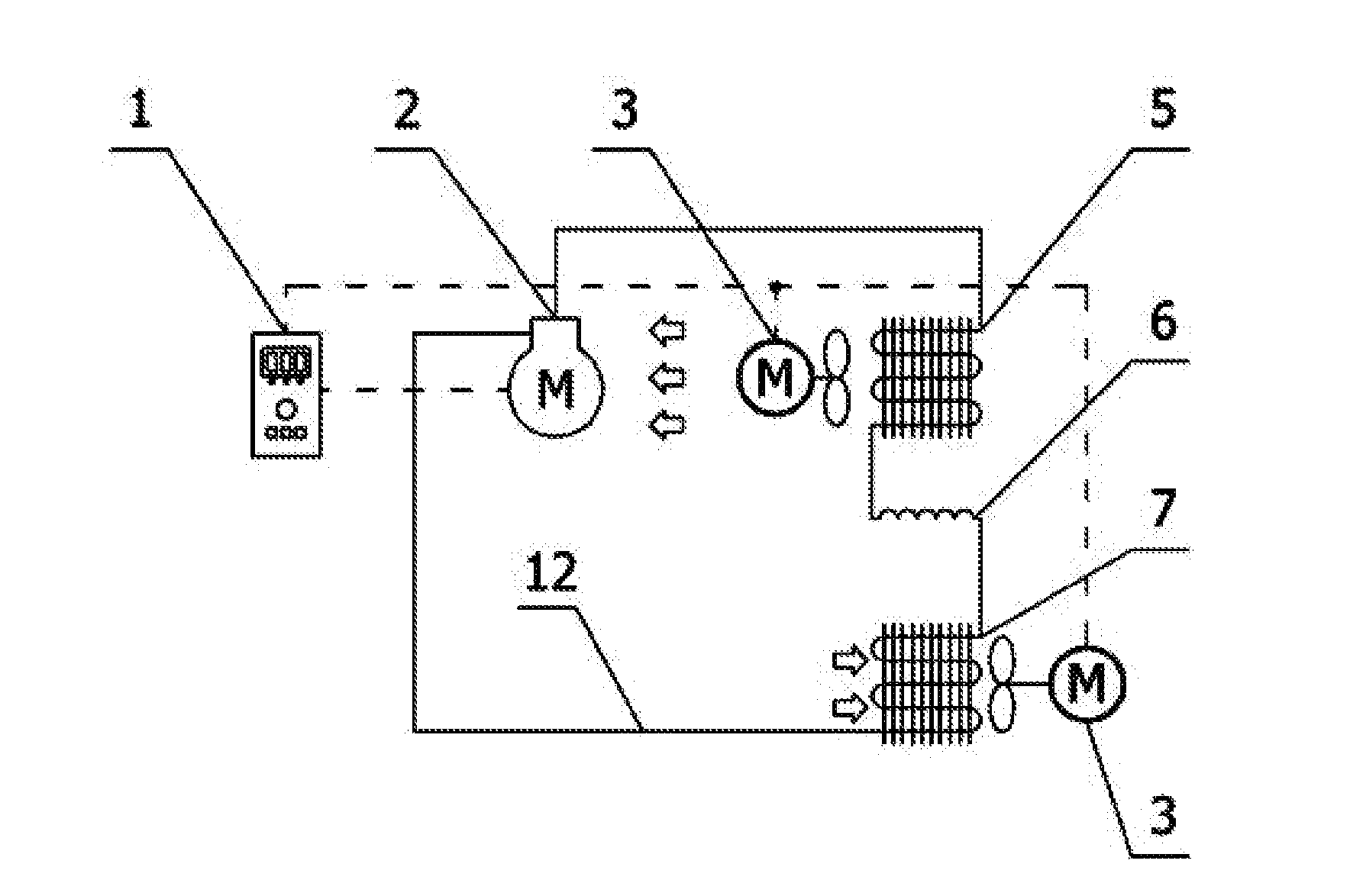

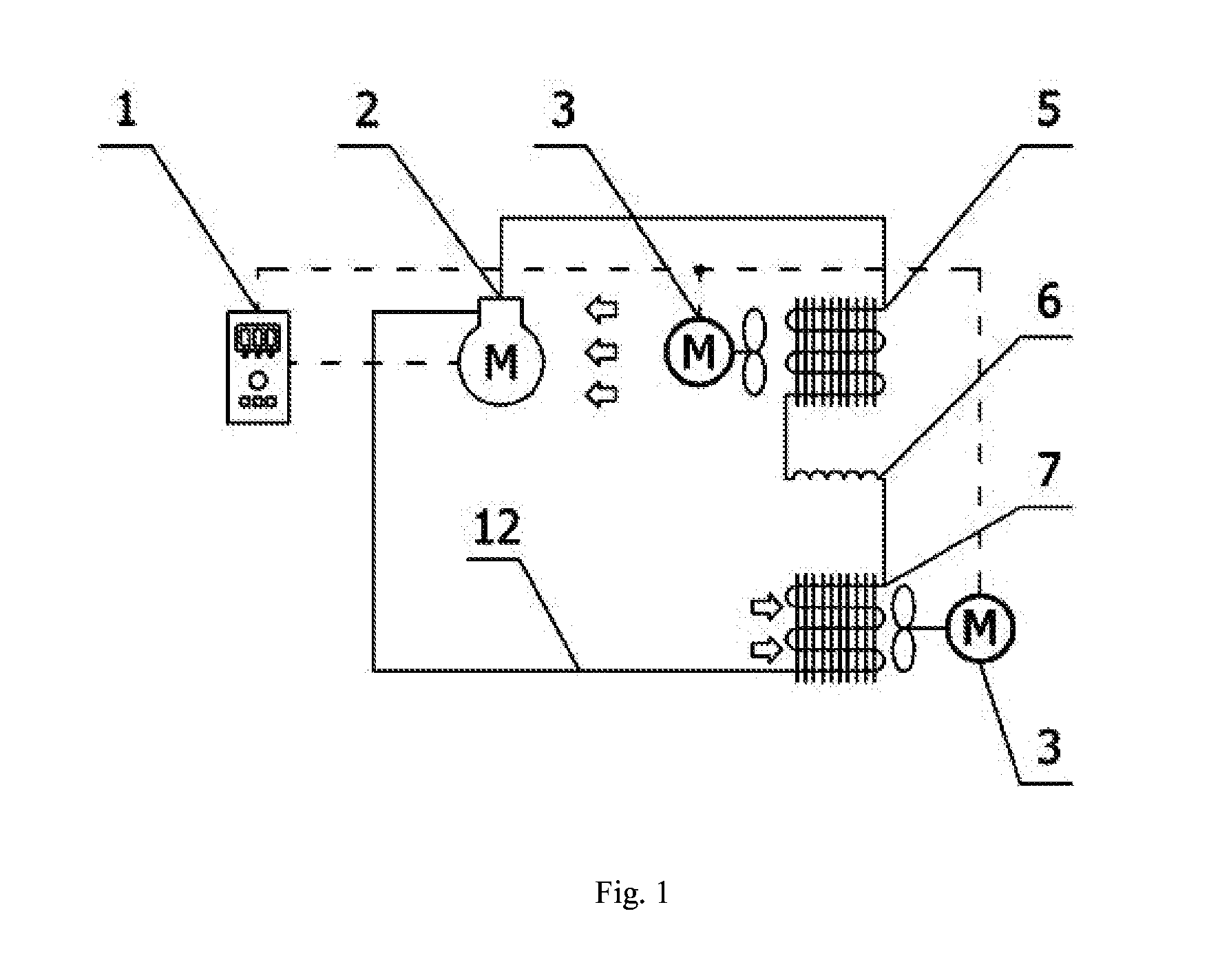

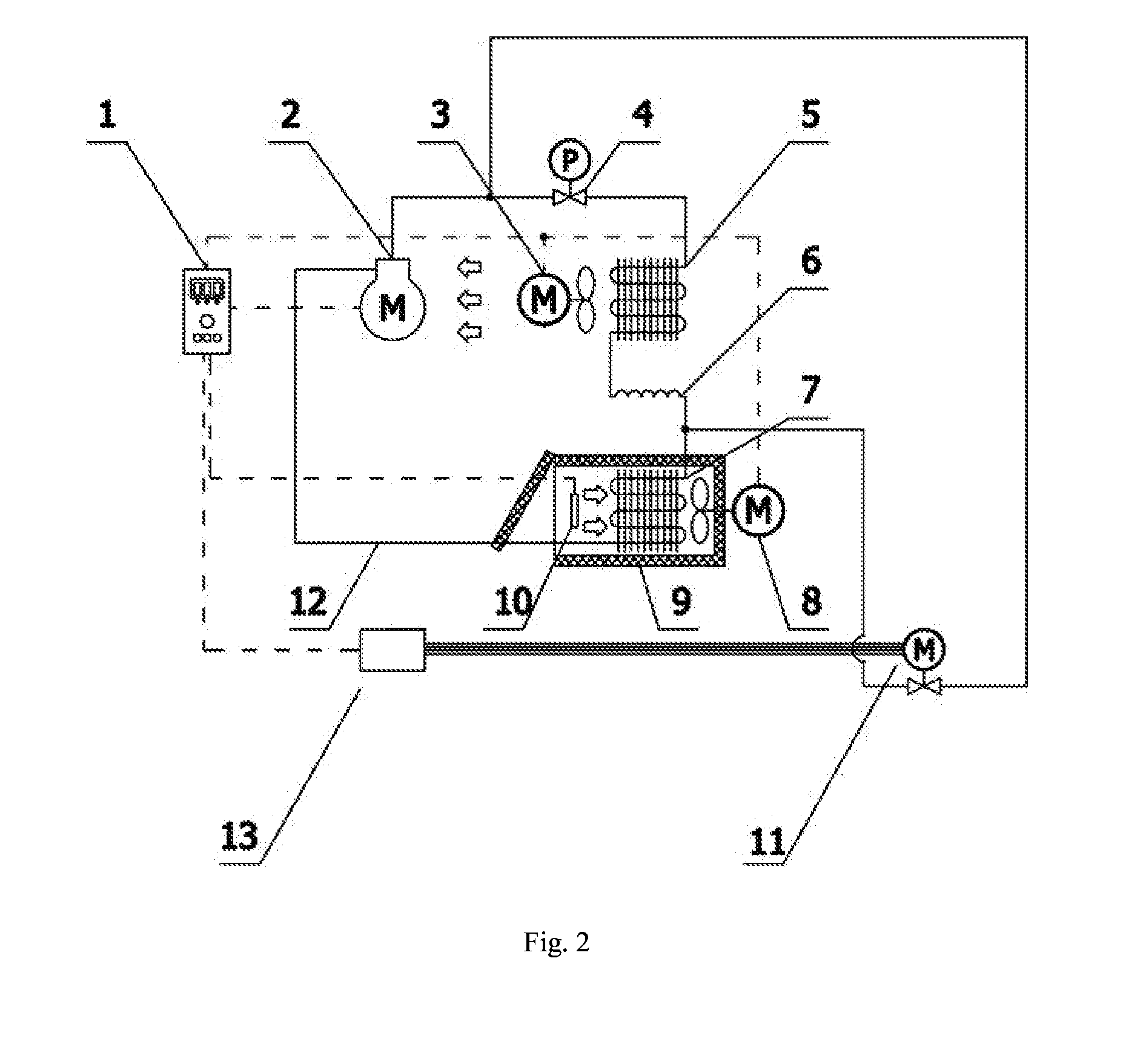

[0040]Operation of the refrigerating capacity control device can be understood by reference first to a traditional refrigerating device as shown in FIG. 1 and then by reference to the current invention as shown in FIG. 2. A refrigerating capacity control device comprises a controller (1), a compressor (2), a condenser fan (3) , a pressure regulating valve (4), a condenser (5) , a throttling device (6), an evaporator (7), circulating fan or pump (8), chamber or bath (9) requiring temperature control, temperature sensor (10), an electronic expansion valve for hot-gas bypassing (11), refrigerating pipelines (12) and a control panel (13) for driving an electronic expansion valve. Wherein, the compressor (2), the condenser (5), the throttling device (6), and the evaporator (7) connected sequentially by refrigerating pipeline (12), condenser fan (3) for the condenser (5) , chamber or bath (9) requiring temperature control and circulating fan or pump (8) for forced convection are parts for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com