Shoe last and method for providing a shoe having an improved heel rest

a technology of heel rest and shoe, which is applied in the field of footwear accessories and manufacturing methods, can solve the problems of not being able to work in harmony with the human foot, the heel of a human foot is not elevated, and the shoe cast cannot function as a shoe last, so as to relieve the pressure at the ball area of the foot, increase the pressure at the area of the ball, and increase the effect of body weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

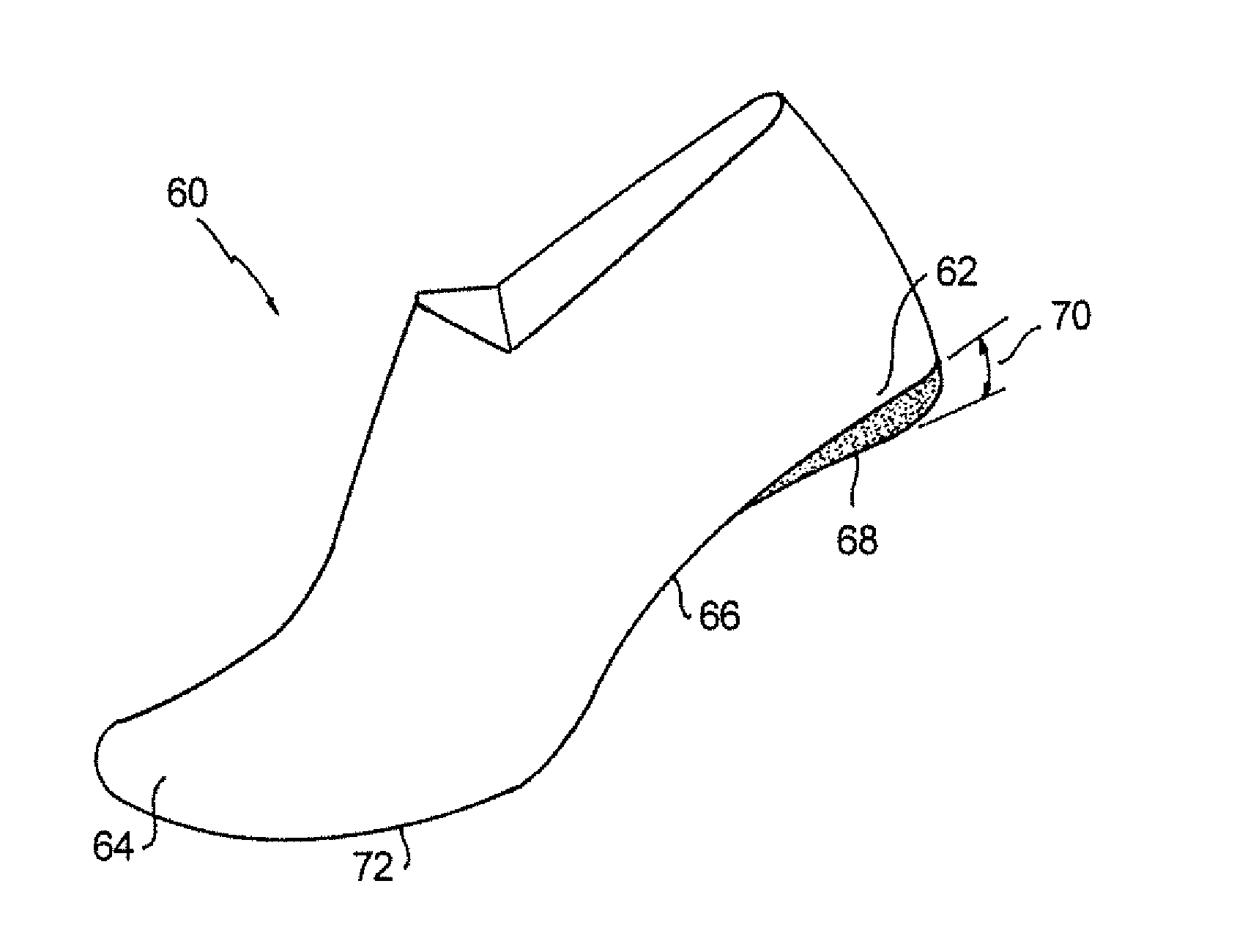

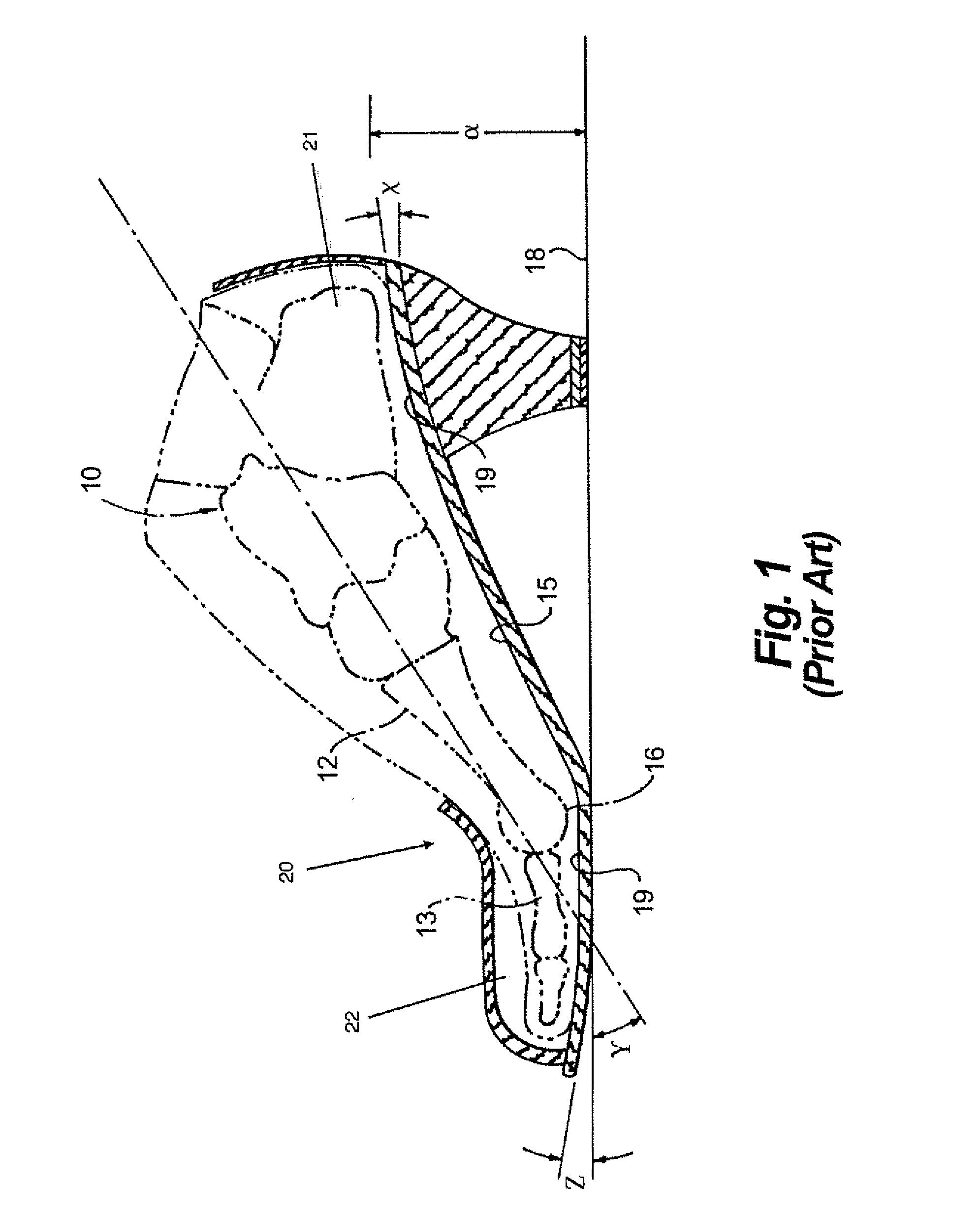

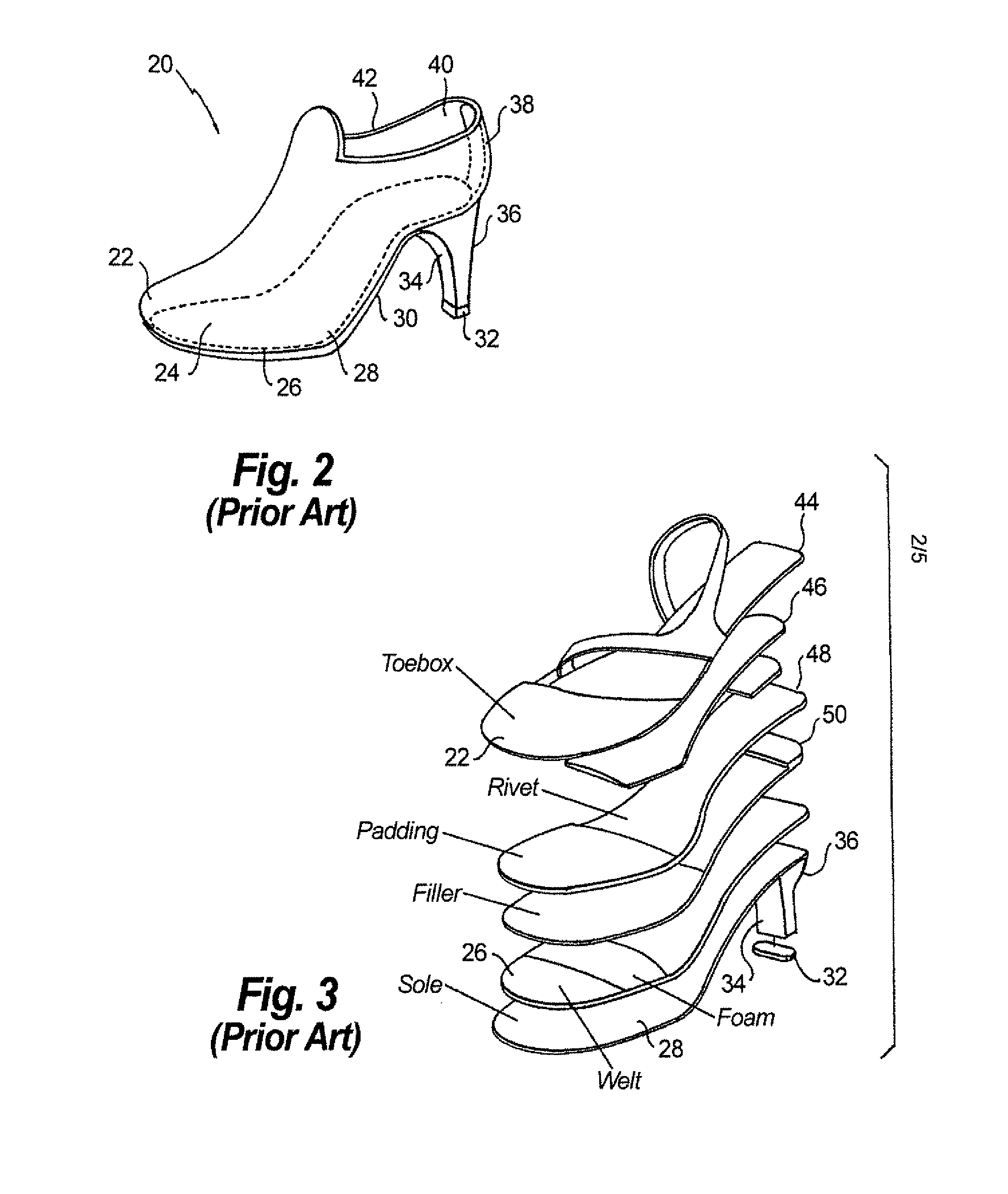

[0041]Embodiments of the present disclosure will now be described with reference to the appended figures in which like reference numerals designate identical, similar or corresponding elements in each of the several views. In the following description, well-known functions or constructions are not described in detail to avoid obscuring the present disclosure in unnecessary detail. The drawings are not intended to limit the scope of this invention, which is set forth with particularity in the claims as appended or as subsequently amended, but merely to clarify and exemplify the invention. It is to be understood that the techniques, systems, compositions and operating structures in accordance with the present disclosure may be embodied in a wide variety of sizes, shapes, forms and modes, some of which may be quite different from those in the disclosed embodiment. Consequently, the specific structural and functional details disclosed herein are merely representative, yet in that regard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com