Exhaust system for diesel vehicles

a technology for exhaust systems and diesel vehicles, applied in the direction of exhaust treatment, flanged joints, mechanical devices, etc., can solve the problems of inability to rotate the two pipe sides with respect to each other, and achieve the effect of reducing the thickness of the fa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

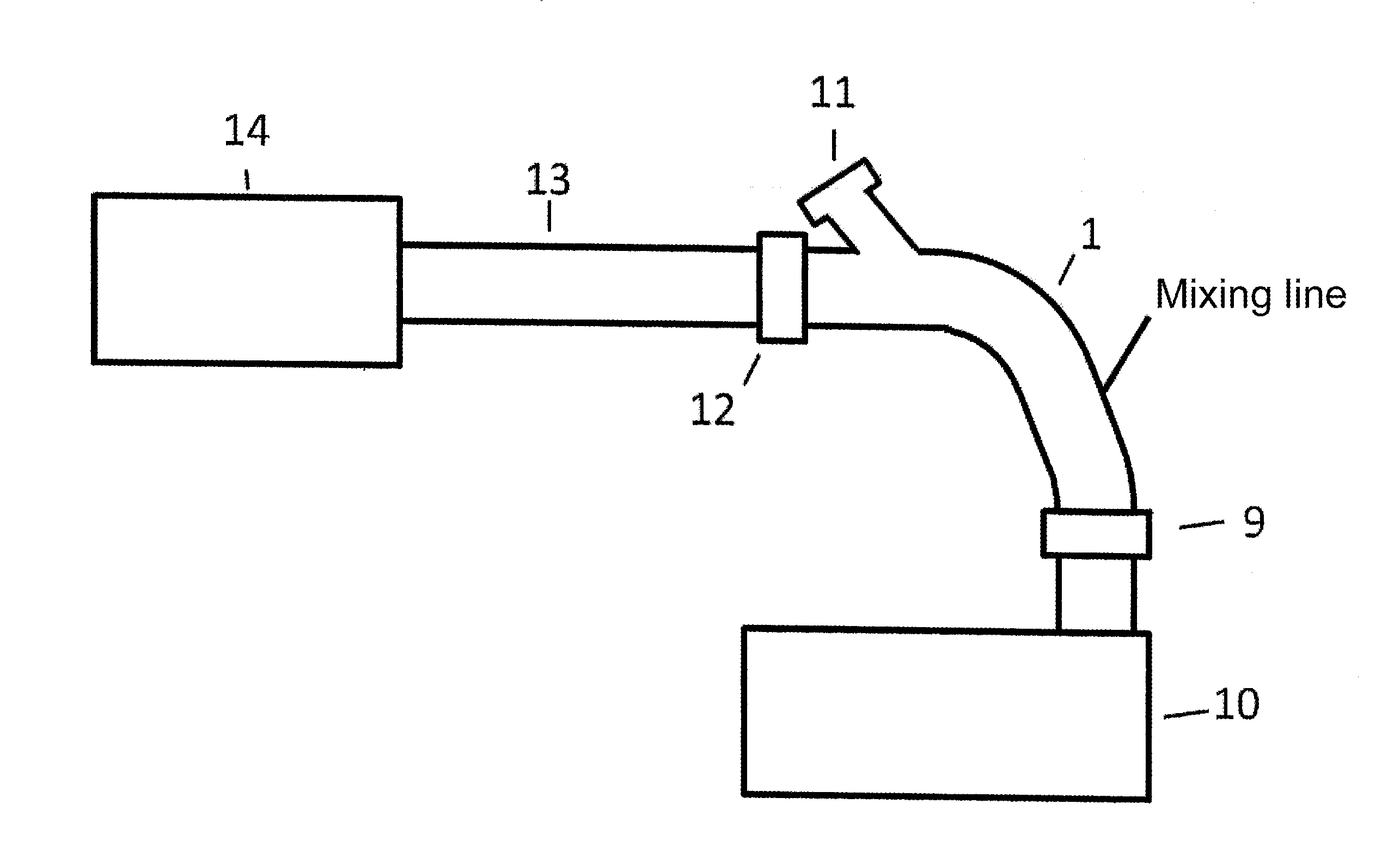

[0027]The present invention illustrates a screw connection, which facilitates the adjustment of the two pipes with respect to each other prior to tightening the screws, in any arbitrary angular position and thus independently of the hole pattern of the screw flange.

[0028]Flexible flange connection 9 (FIG. 4) is “AdBlue-tight”; tight against DEF, AUS 32 according to ISO 22241, and tight against all common fuels and their condensates as well as tight against all exhaust gases from internal combustion engines.

[0029]The flange connection illustrated in FIG. 1 is a screw connection between two pipes 1, 8. One pipe side 8 is fixedly welded to a flange or flange face 4. The mating side permits the free torsion of pipe 1, due to a loose flange 2, and thus a variable adjustment independently of the hole pattern of the flange. Following the desired adjustment of the two pipes 1, 8 with respect to each other, flanges 2, 4 or flange faces are screwed to each other. Seal 3 is pressed between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com