Method and device for sensing humidity with reversible molecular dimerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

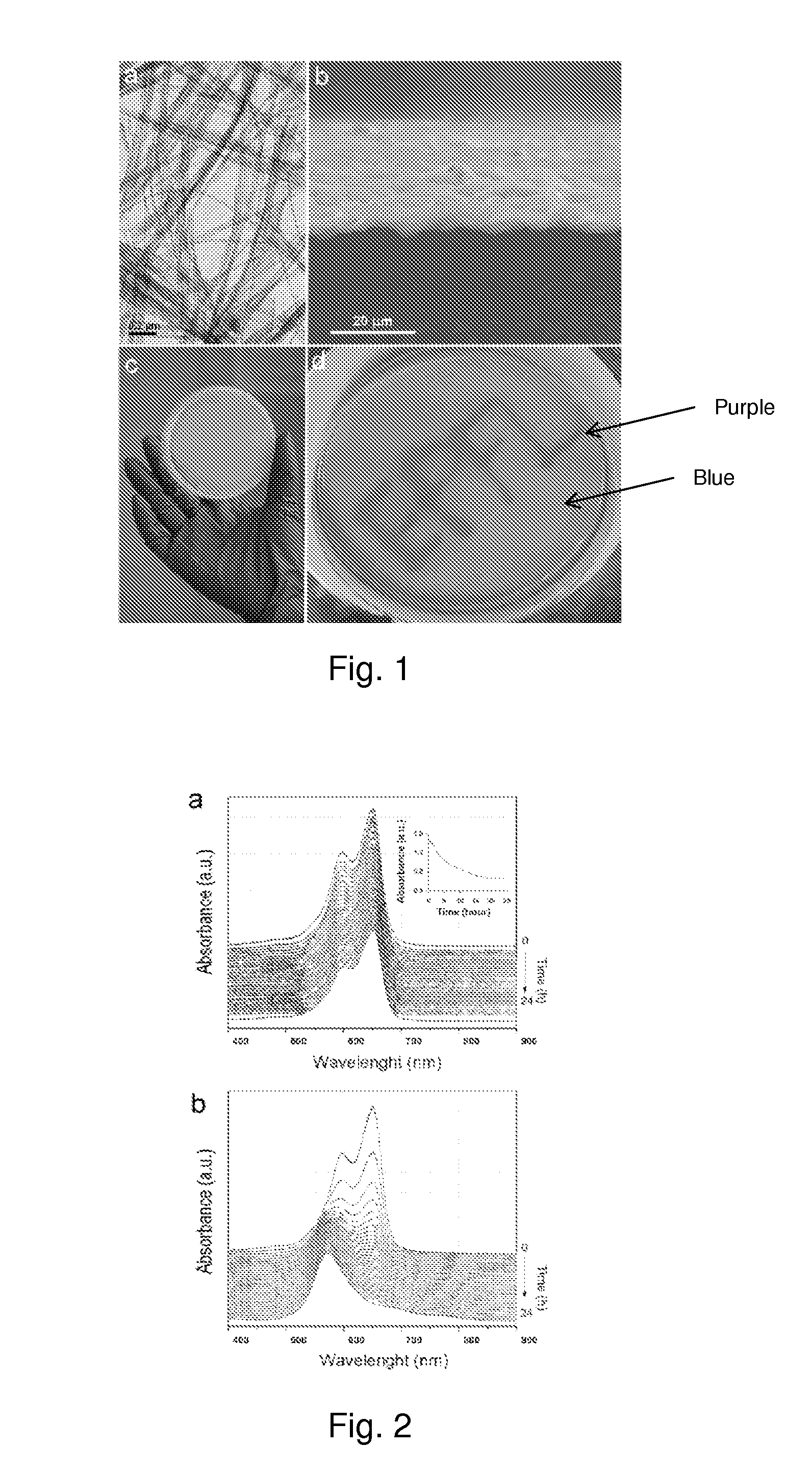

Image

Examples

examples

Materials

[0031]Titanium dioxide (anatase, TiO2), sodium hydroxide (NaOH), methylene blue (MB) and hydrochloric acid (HCl) pure grade, were obtained from Sigma-Aldrich and were used without further purification. Standard pH buffer solutions were obtained from Metrohm. Microscopic glass slides for film preparation were purchased from Menzel GmbH & Co KG.

Preparation of Protonated Titanate Nanowires and their Suspension

[0032]Protonated titanate nanowires were prepared by a two-step hydrothermal process. The details about the typical synthesis procedure are given elsewhere.77

[0033]To prepare nanowire suspensions TiONW powder (2.4 g) is dispersed in 100 mL of 2-propanol (99.8% Merck), and the mixture is homogenized with an ultrasonic tip (Bandelin Sonopuls, Microtip MS73) at 10% amplitude for 30 min.

[0034]Thin films were fabricated on microscopic glass substrates. The nanowire solution of 24 mgmL−1 in isopropyl alcohol is doctor bladed using a 40 μm spacer (3M) to obtain the desired film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com