Process Stream Decontamination Systems and Methods with Recirculation of Decontaminant

a technology of decontamination system and decontaminant, which is applied in the direction of process and machine control, hydrogen sulfide, energy based chemical/physical/physical-chemical processes, etc., can solve the problems of pipeline corrosion, narrowing of the line, and corroding pipelines, so as to achieve accurate and continuous monitoring and identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

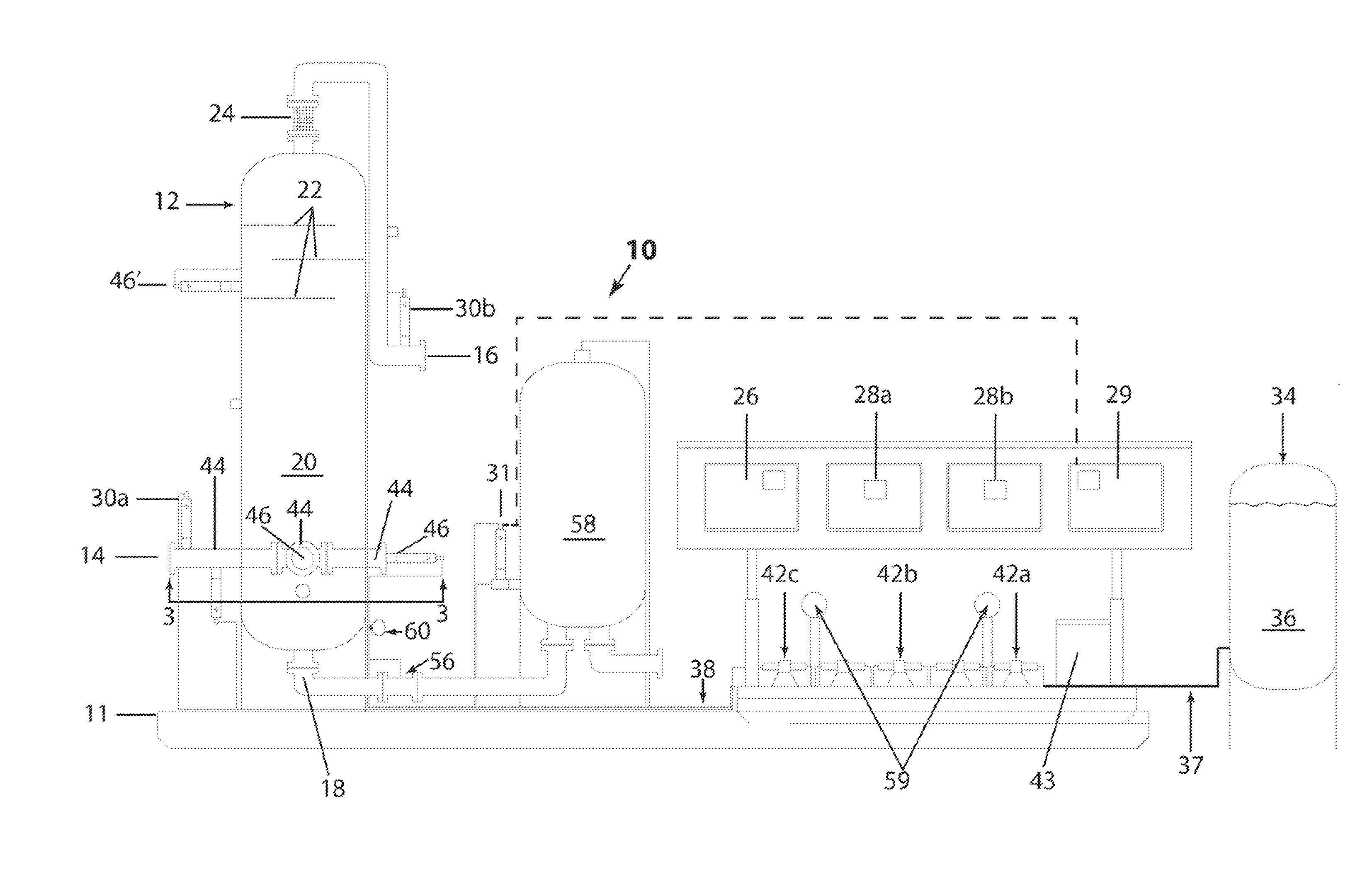

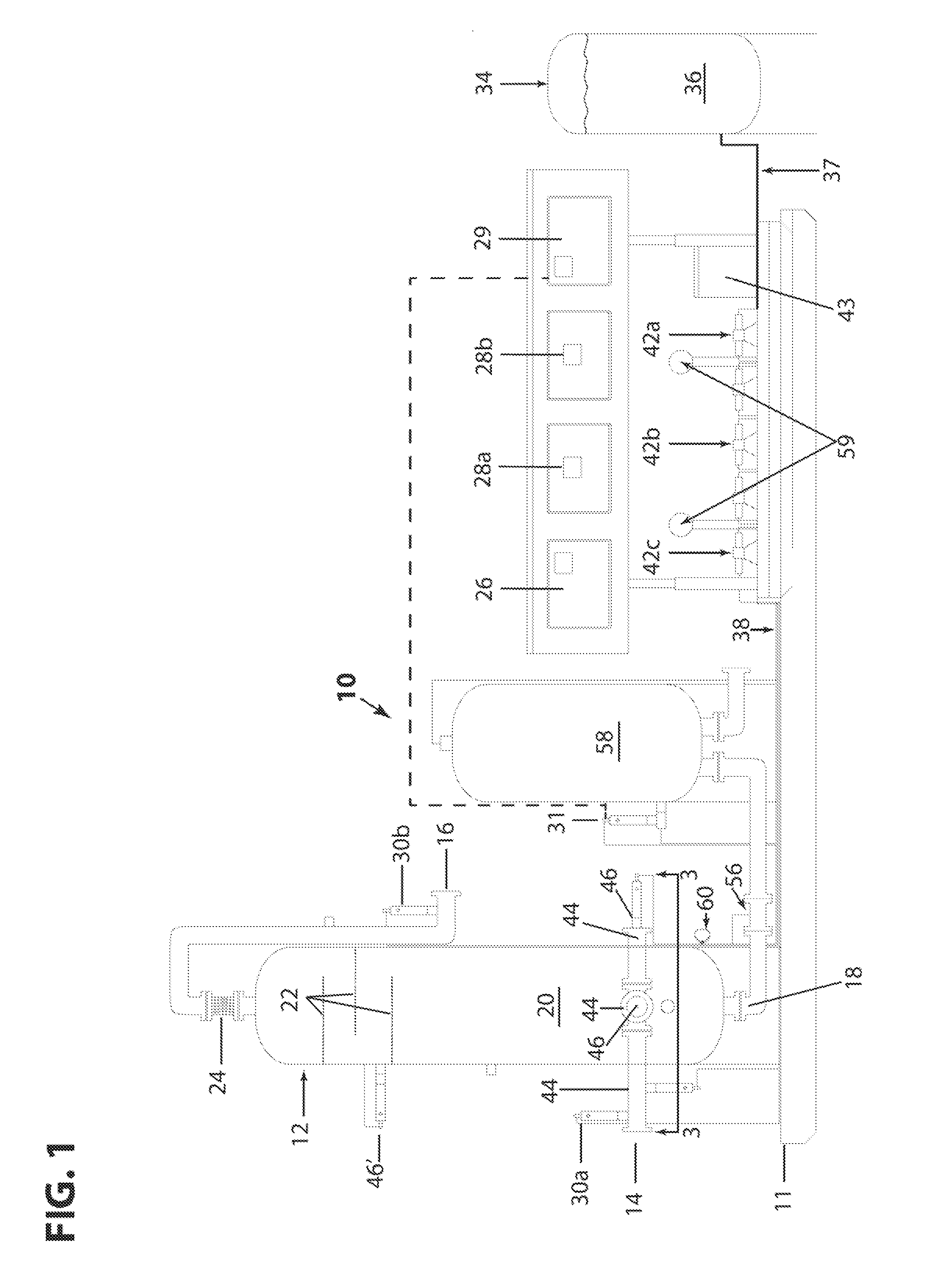

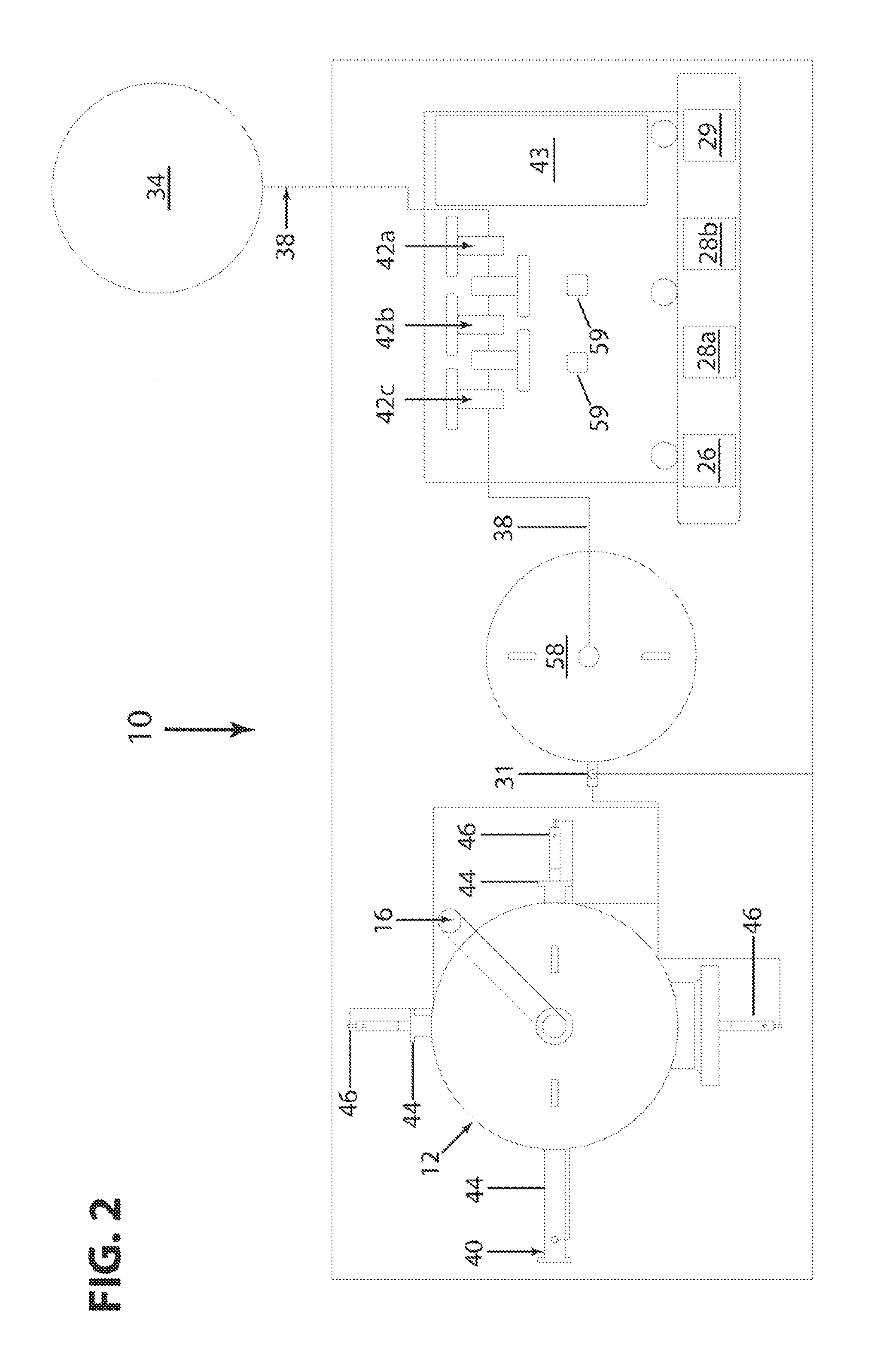

[0024]FIGS. 1 and 2 illustrate an exemplary decontamination system 10 that is constructed in accordance with the present invention. The decontamination system 10 is operably associated with a process stream that contains at least one contaminant of interest to be neutralized. In particular embodiments, the process stream can be natural gas flowing through a pipeline. The process stream could also be a flow of other liquids, such as crude oil or water. Typical contaminants include hydrogen sulfide (H2S), mercaptans, carbon dioxide (CO2), oxygen (O2), water (H2O) and biological populations. In addition, a detected “contaminant,” as discussed herein, can include conditions that can lead to contaminants, such as conditions that are ideal for hydrate formation or corrosion.

[0025]In certain embodiments, the decontamination system 10 of the present invention can be configured as a portable, modular system that is designed to be readily moved and integrated into an existing facility having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com