Sulfur Containing Alpha-Alumina Coated Cutting Tool

a technology of alpha-alumina and cutting tools, applied in manufacturing tools, other chemical processes, coatings, etc., can solve the problems of high deposition rate, inability to control phase content, and pronounced dog-bone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

α-Al2O3 Coatings

[0038]Cemented carbide substrates for cutting inserts with a composition of 6.0 wt % Co and balance WC (hardness about 1600 HV) were coated with a Ti(C,N) layer by applying MT-CVD using 0.6 vol % CH3CN, 3.8 vol % TiCl4, 20 vol % N2 and balance H2. The thickness of the Ti(C,N) MT-CVD layer was about 5 μm.

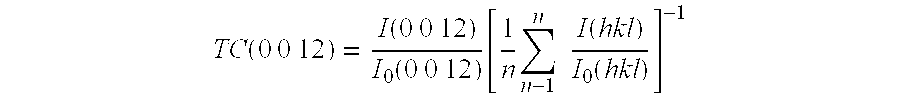

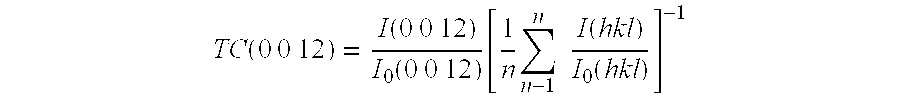

[0039]Onto this Ti(C,N) layer of separate substrate samples different layers consisting of about 8 μm α-Al2O3 were deposited. The coating parameters are given in Table 1, and the texture coefficients, TC(0 0 12), measured by X-ray diffraction, and the sulphur concentrations in the α-Al2O3 coatings, measured by SIMS, are given in Table 2.

[0040]The deposition of α-Al2O3 was started by depositing a 0.05 μm to about 1 μm, preferably 0.5 μm to about 1 μm, thick bonding layer on top of the MTCVD layer from the system H2—N2—CO—TiCl4—AlCl3 at a pressure of 50 to 100 mbar. For the preparation of the bonding layer the MTCVD layer was treated with a gas mixture of 3 vol % TiCl4,...

example 2

Edge Toughness Tests

[0044]The samples 1a to 4b of Example 1 were tested with respect to edge toughness (chipping resistance) in longitudinal turning of cast iron (GG25) using the following cutting parameters:

Work piece: GG25; cylindrical bar

Insert type: SNUN

Cutting speed: vc=400 m / min

Feed (f)=0.4 mm / rev

Depth of cut: ap=2.0 mm

Remarks: dry turning

[0045]The inserts were inspected after 2 and 4 minutes of cutting. As shown in Table 3, compared to the coating of the prior art, the edge toughness of the samples was considerably enhanced when the coating was produced according to this invention.

TABLE 3Edge ToughnessFlaking of the edge line (%)Flaking of the edge line (%)Coatingafter 2 minutesafter 4 minutes1a22341b18322a18412b12323a19293b X283c X044a18334b X03X = invention

example 3

Turning Tests

[0046]The samples 6, 8, 10 and 12 of Example 1 were tested in carbon steel (C45) without coolant using the following cutting parameters:

Work piece: C45

Insert type: WNMG080412-NM4

Cutting speed: vc=280 m / min

Feed (f)=0.32 mm / rev

Depth of cut: ap=2.5 mm

Remarks: dry turning

[0047]The end of tool life criterion was flank wear >0.3 mm. Three edges of each variant were tested.

TABLE 4Turning Test resultsCoatingTool Life (min) 613.2 815.510 X21.312 X32.2X = invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com