Pilotless, unplugged combustion control system

a technology of combustion control and pilotless power supply, which is applied in the direction of combustion process, combustion regulation, fuel supply regulation, etc., can solve the problems of increasing the cost of water heater power connection by about $100, and the cost of initial power supply to the water heater by approximately $150, so as to reduce standby power consumption, improve system efficiency, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

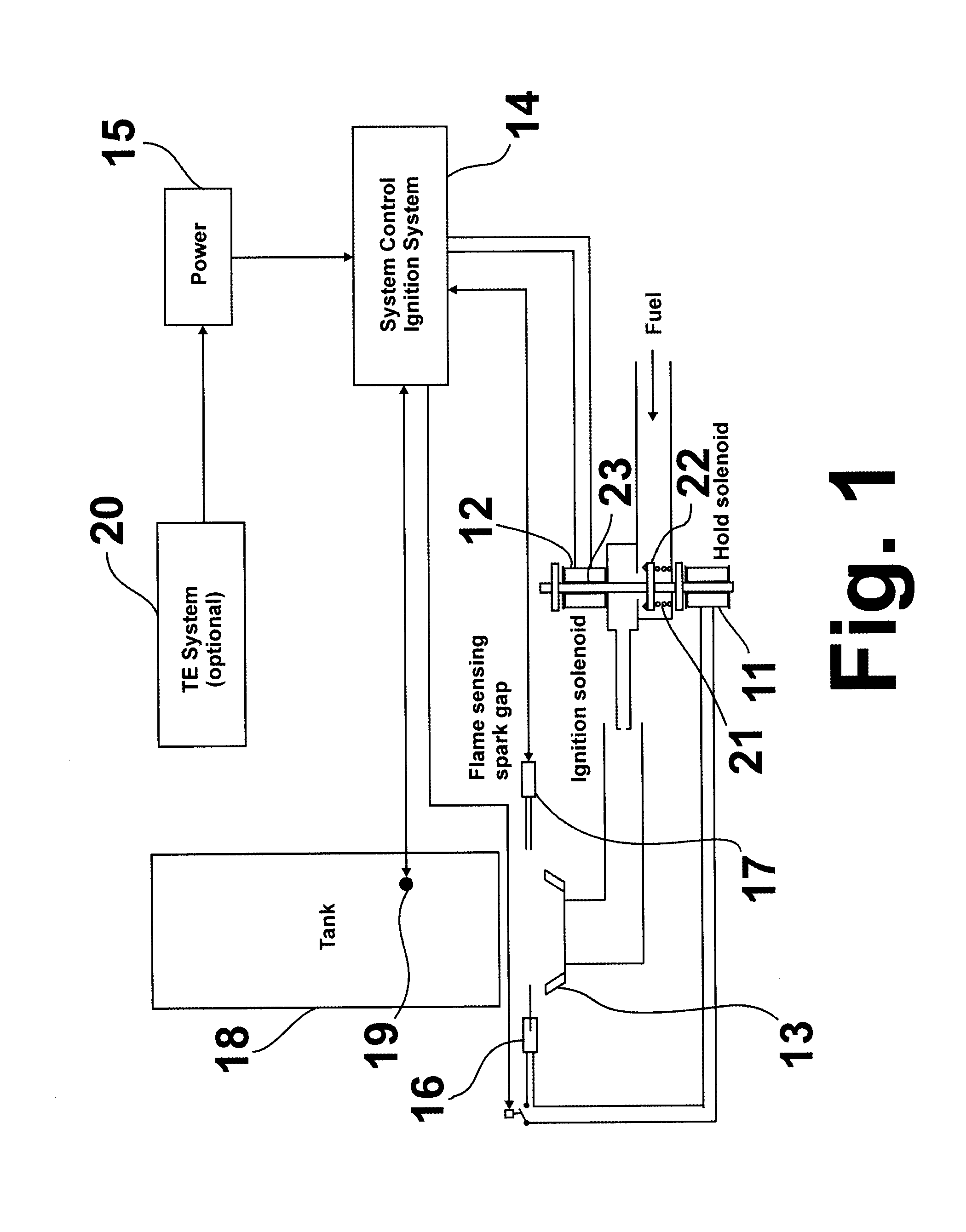

Image

Examples

Embodiment Construction

[0022]The invention disclosed herein is a combustion control system for fuel-fired heating equipment and appliances which conventionally employ a pilot burner and pilot flame for ignition of the main burner employed therein, including gaseous fuel-fired residential and commercial water heaters and gas-fueled fireplaces, which eliminates the need for a pilot burner and pilot flame. Although the system generally is described herein for use with a water heater, it will be appreciated that the system as described may be employed in any heating apparatus or appliance which conventionally uses a pilot flame and burner for main burner ignition, and such applications are to be understood to be within the scope of this invention. Included within the range of applications to which this invention may be applied are residential, commercial, and industrial water heaters, residential and commercial space heaters and wall furnaces, residential and commercial stoves and ovens, gas-fired fireplaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com