Downhole pump assembly

a pump assembly and pump technology, applied in the direction of fluid removal, positive displacement liquid engine, borehole/well accessories, etc., can solve the problems of double financial expenses, two tubing strings, two rod drives, and two tubing strings running operations entail great labor consumption, so as to increase the overhaul period and improve the reliability of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

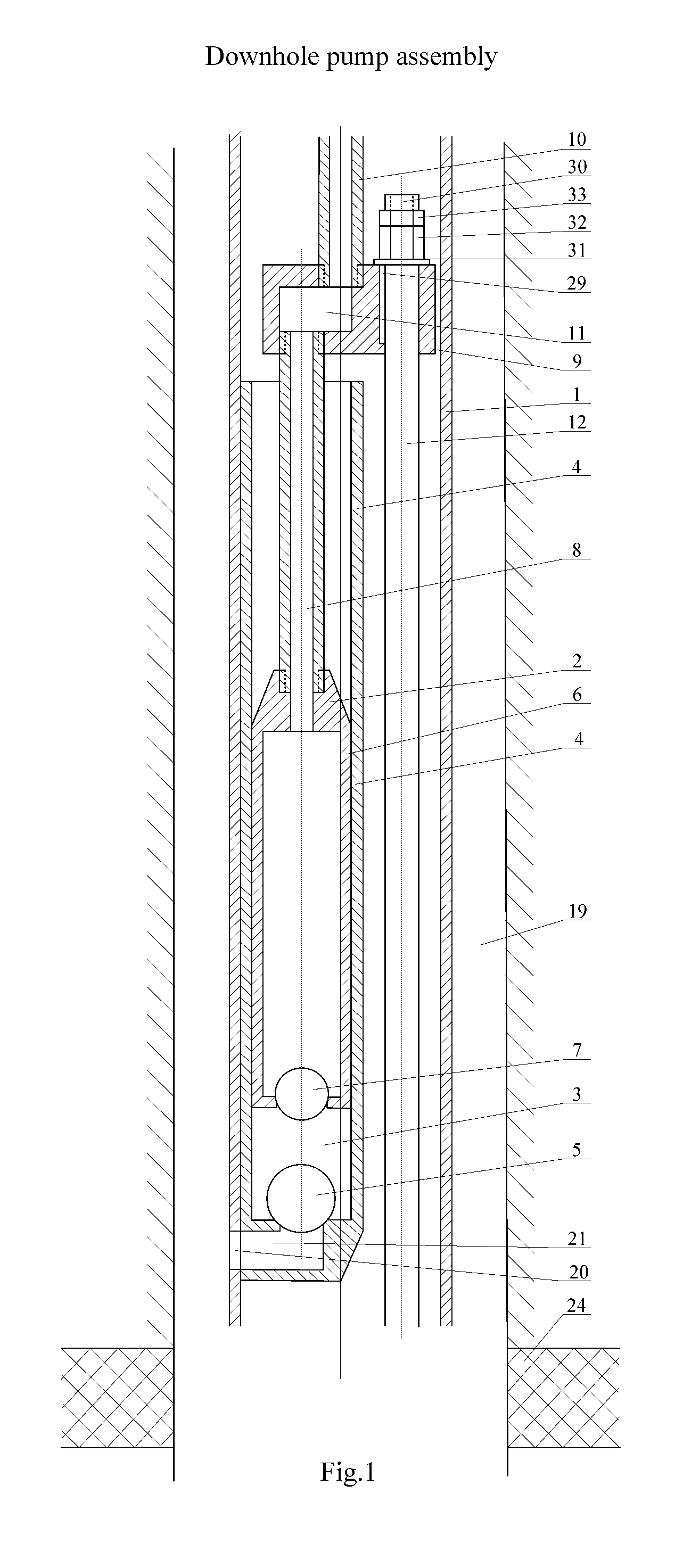

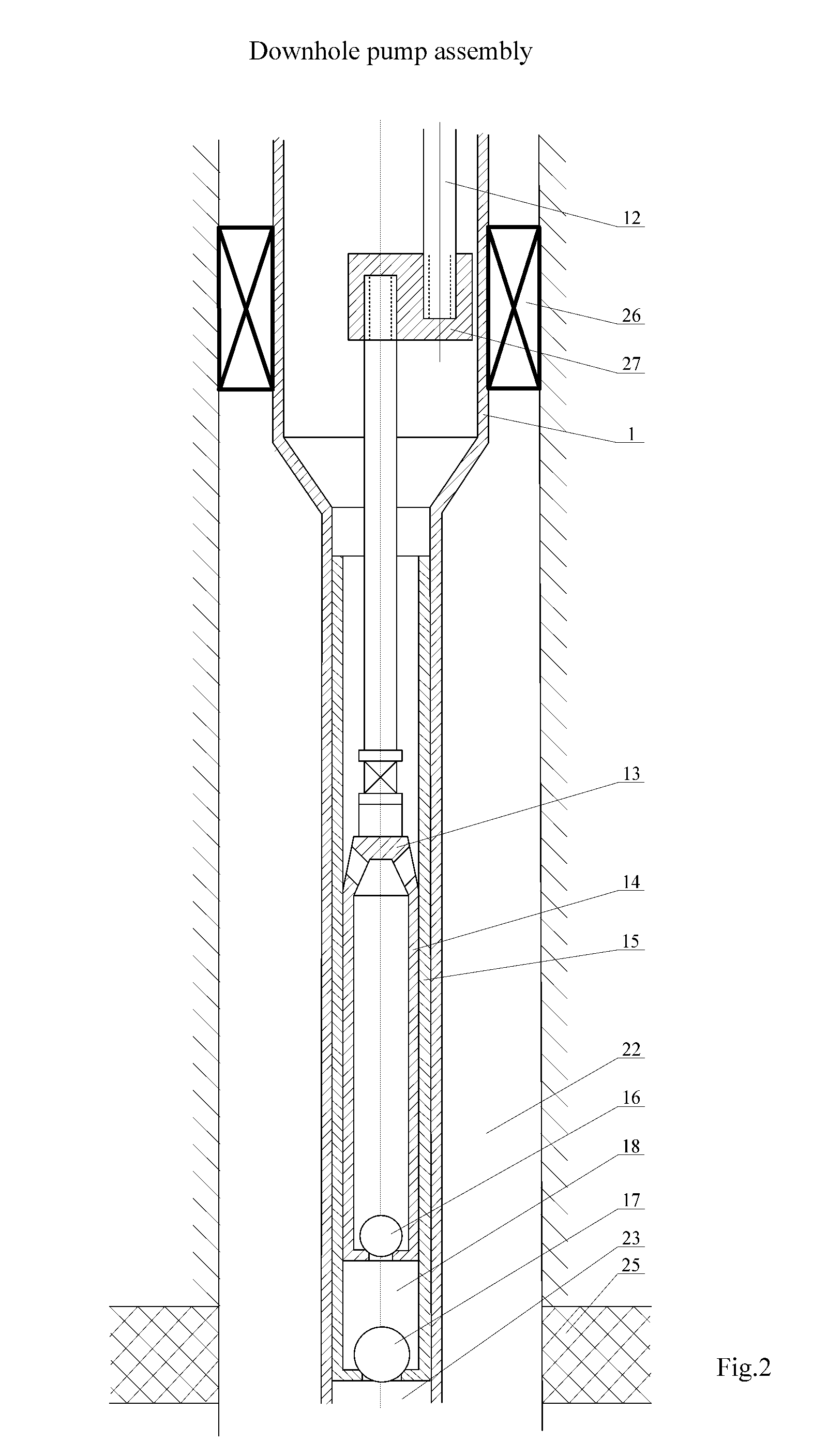

[0018]The innovative downhole pump assembly consists of a body 1, an upper oil-well sucker-rod pump 2 containing a pump chamber 3 in a cylinder 4 with a suction valve 5 and a hollow plunger 6 with an discharge valve 7 in its lower part. The plunger 6 is connected with a hollow rod string 8 through a crossbar 9 with a joint hollow rod string 10. The axis of the upper oil-well sucker-rod pump 2 is biased from the axis of the downhole pump assembly body 1. In the crossbar 9 there is a channel 11 which connects the chamber of the plunger 6 with the chamber of the joint hollow rod string 10 (FIG. 1). Moreover, the crossbar 9 is connected with an upper end of the rod string 12 of a lower oil-well sucker-rod pump 13 (FIG. 2) the lower end of which, in turn, is connected with a made hollow plunger 14 of the lower oil-well sucker-rod pump 13. The rod string 12 is in the moon-shaped chamber formed by the outside surface of the upper oil-well sucker-rod pump 2 and the inner surface of the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com