Weatherstrip assembly for sealing between a frame and a closure member and a method for producing the same

a weather strip and frame technology, applied in the field of weather strip assembly for vehicles, can solve the problems of difficult manipulation of weather strip assembly, and achieve the effects of reducing friction between the closure member, facilitating mounting of the weather strip assembly, and increasing the ease of mounting the weather strip assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

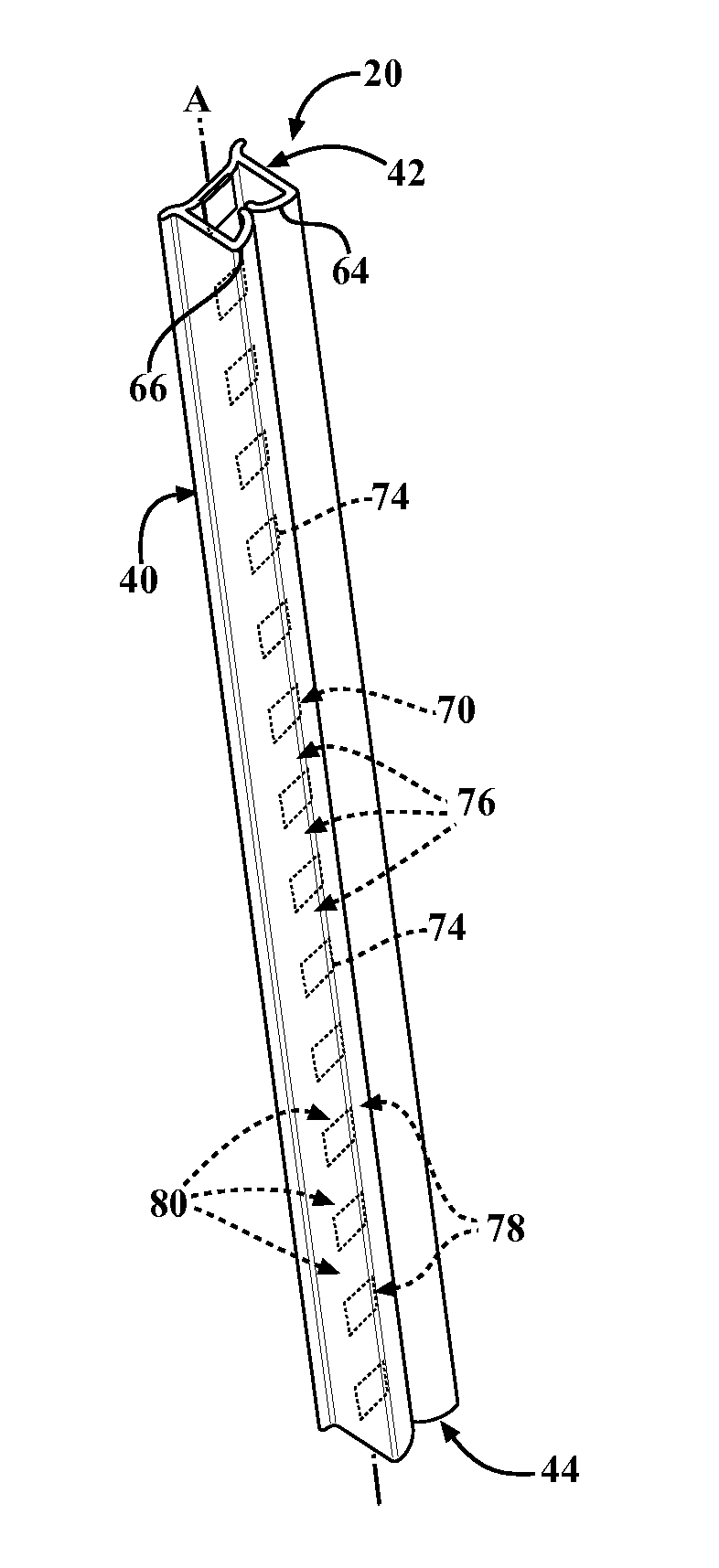

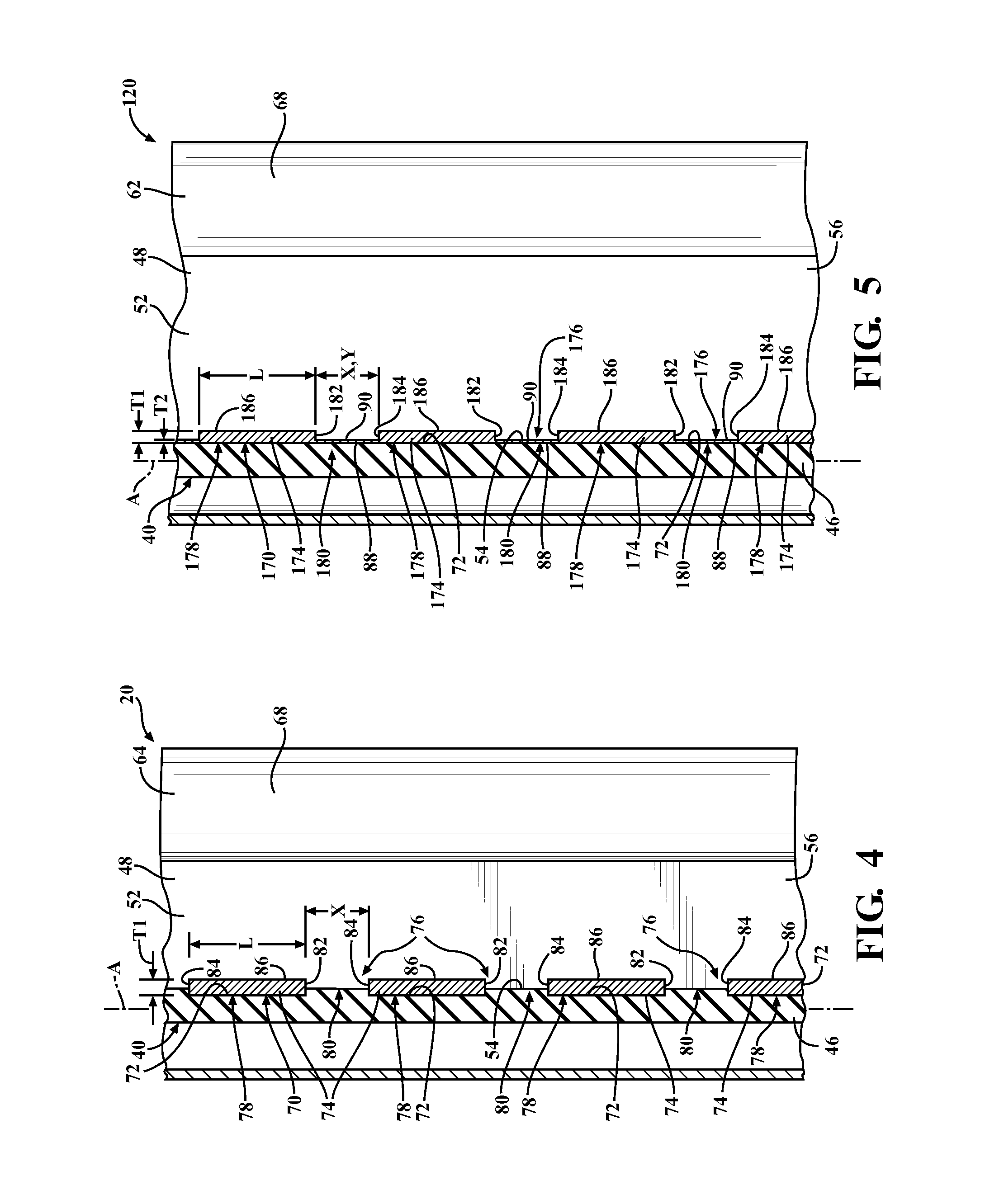

[0027]Referring to the Figures, wherein like numerals indicate like or corresponding parts throughout the several views, a weatherstrip assembly 20 for sealing between a frame 22 and a closure member 24 of a vehicle 26 is generally shown in FIG. 1. The vehicle 26 is typically a passenger car or a truck. However, it is to be appreciated that the vehicle 26 may be any configuration for providing transportation. The vehicle 26 may include a vehicle body 28 and a plurality of doors 30 pivotally coupled to the vehicle body 28. However, it is to be appreciated that the doors 30 may be coupled to and movable relative to the vehicle body 28 in any configuration.

[0028]The frame 22 may be further defined as the door 30. Specifically, as shown in FIG. 1, the door 30 has a body portion 32 and a window frame 34 with the window frame 34 extending outwardly and substantially planar to the body portion 32 and with the body portion 32 and the window frame 34 defining a window 36. Alternatively, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com