Charging a Sacrificial Anode with Ions of the Sacrificial Material

a technology of sacrificial material and anode, which is applied in the direction of building components, building reinforcements, constructions, etc., can solve the problems of unexpected and unacceptable corrosion of steel within the structure, two primary limitations of ordinary galvanic anodes used in steel reinforced concrete, and achieve long-term protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

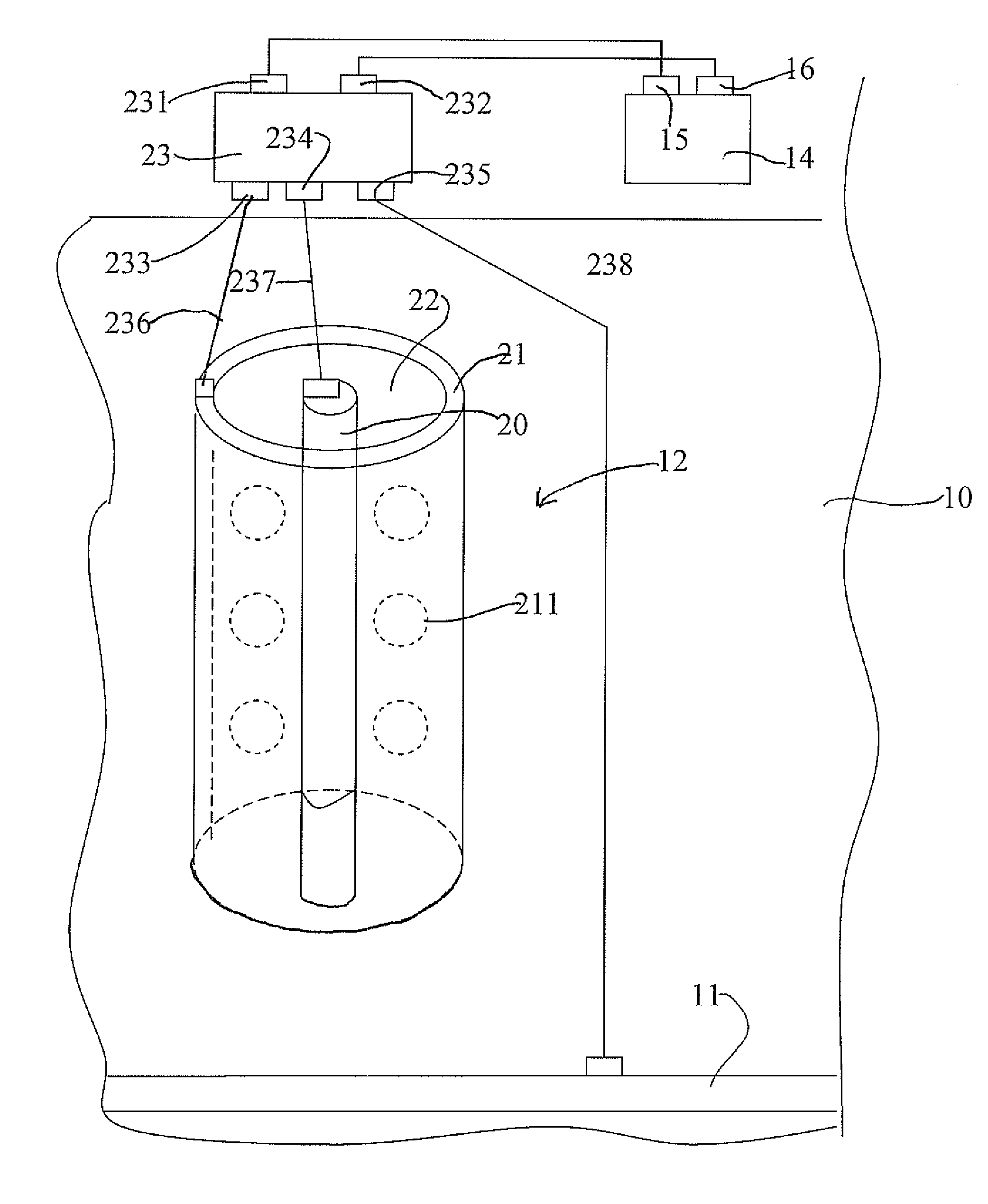

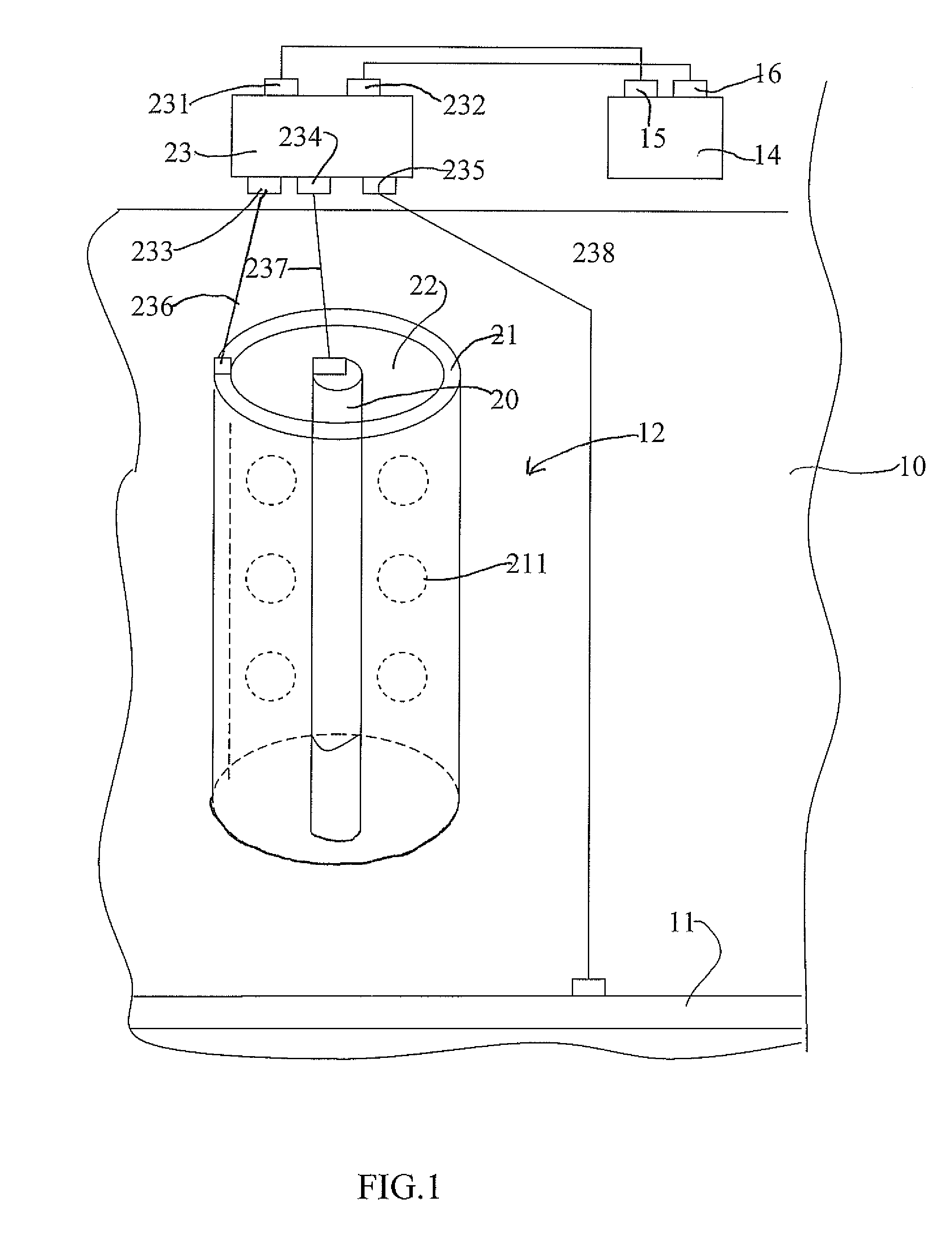

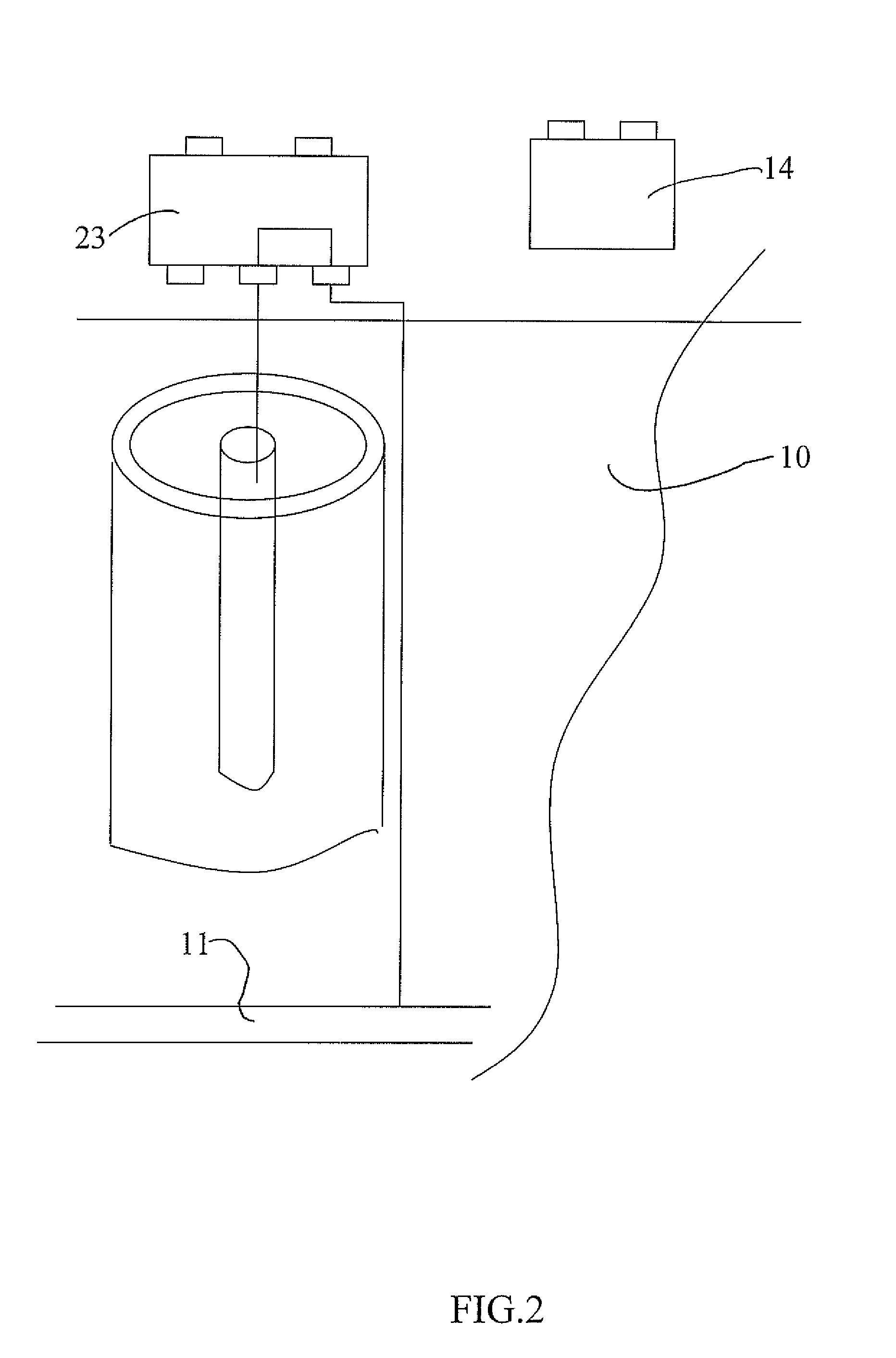

[0133]In one example, a cast zinc anode, 8 cm long with a minimum diameter of 0.7 cm, was located in ZnO / thixotropic paste packed inside a conductive ceramic impressed current anode tube. The zinc paste was made from a solution saturated with LiOH with 2M KOH and 20% ZnO along with carboxymethyl cellulose sodium thickening agent. The paste was packed in the space between the zinc anode and the inner side of the 28 mm tube. Testing has shown that ions can pass through the porous tube walls such that the zinc anode can pass current onto the external steel reinforcing bar even though it is located inside the impressed current anode. Subsequently, charging of the zinc can be accomplished by reversing the flow of ions through the impressed current porous tubular anode by applying an external voltage between the impressed current anode and the sacrificial anode. An applied voltage of around 6-8 Volts resulted in a current of up to 1.6 A to be delivered to the inner zinc anode achieving a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com