Holding Units for Stay in Place Molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

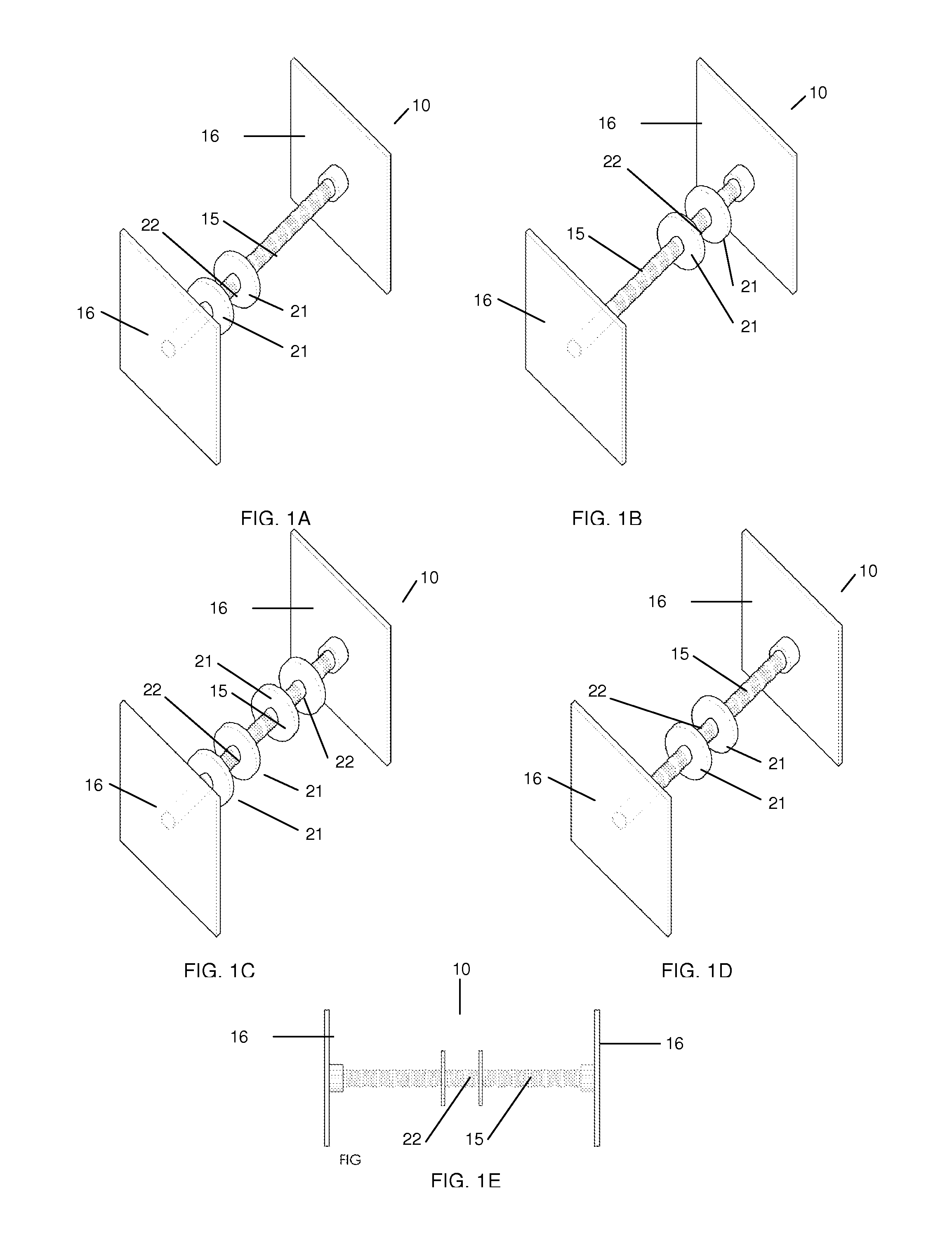

Image

Examples

embodiment 42

[0044]On the other hand, mold embodiment 42 as illustrated in FIG. 12 has a closing unit 36, enclosing the internal cavity 11 of the mold 42. Said closing unit 36 may be made of fiber cement panel that has been cut off at the convenient size in order to enclose the internal cavity 11 of the mold 42. Said closing unit 36 may be installed once the mold is already assembled at the construction site and previous to fill the internal cavity 11 of the mold 42 with liquid concrete mixture.

embodiment 40

[0045]A process directed to manufacture of the mold embodiment 40 is illustrated in FIGS. 13A-13D. In the first step, a series of holding units 10, having only one supporting plate 16 are permanently fastened at a predetermined positions of the internal surface 45 of the fiber cement panel 12 in a pattern of a series of multiple columns, each of said column being apart from the others at a predetermined distance and each holding unit 10 within a column being apart from the next holding 10 unit at a predetermined distance. The holding units 10 having a single lateral plate 16 are permanently fastened or fixed on the interior surface 45 of the fiber concrete panel 14 by, for instance gluing the exterior surface 17 of the said single lateral plate 16 to the interior surface 45 of panel 12; thus, the holding units 10 have no physical contact with the exterior surface 44 of the concrete panel 12. Once the holding units 10 are permanently joined to the interior surface 45 of the panel or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com