Oral/nasal cannula manifold

a cannula and manifold technology, applied in the field of oral/nasal cannula manifolds, can solve the problems of reducing the accuracy of the analysis of the sample by the gas analyzer, reducing the amount of information obtained from the analysis, and undesirable diminished fidelity of the gas sampling flow dynamics, so as to improve the accuracy of the oral/nasal sampling manifold, enhance the performance of the oral collection portal, and improve the accuracy of the oral/nasal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

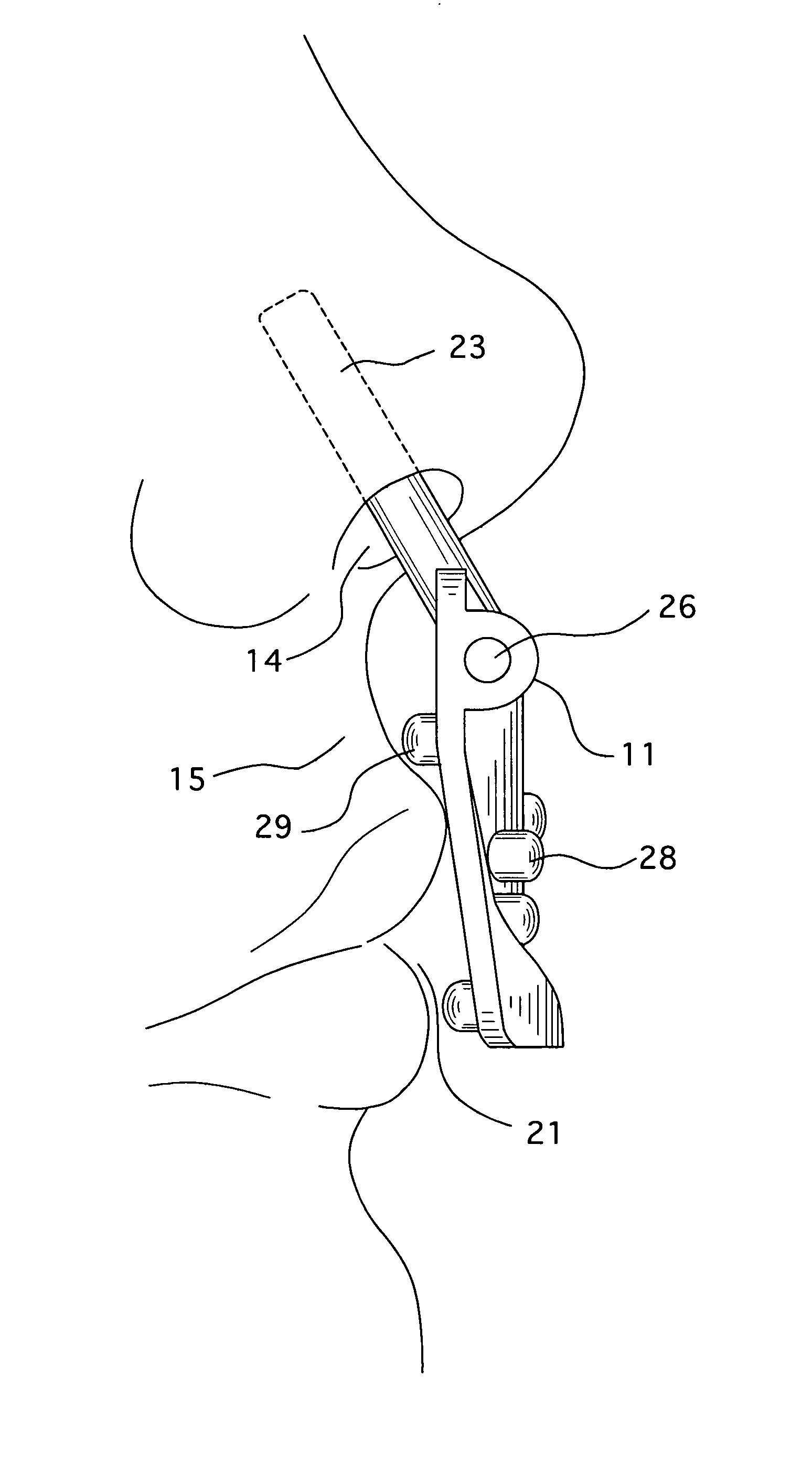

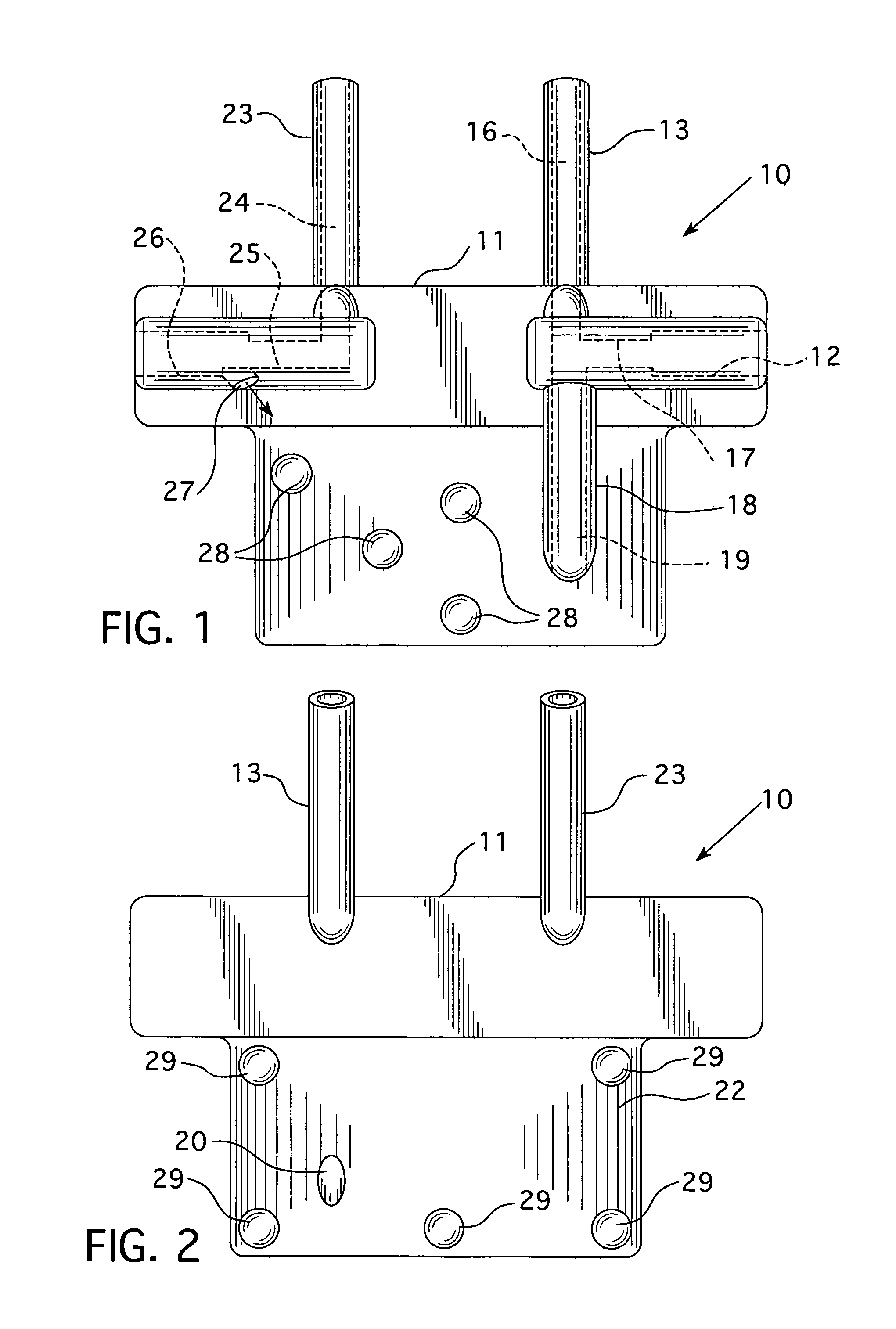

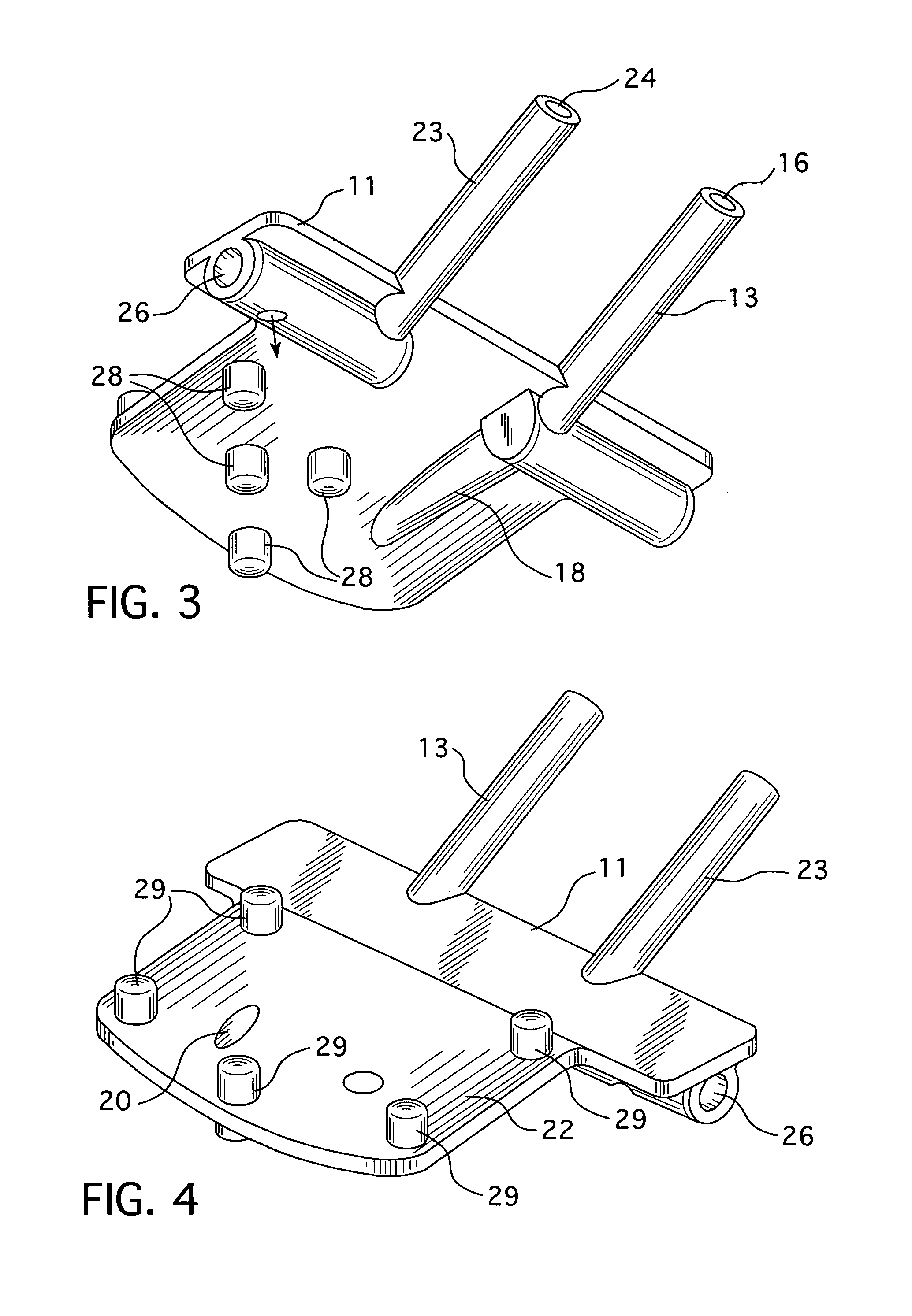

[0021]Referring to the drawings, oral / nasal cannula manifold 10 of the present invention is provided for sampling exhaled breath of a subject and includes a main body portion 11 having formed therein a suction port 12 (FIG. 1) which is dimensioned and adapted to be connected with a collection tube (not shown) to a suction device (not shown) for sampling of exhaled breath of the subject known as a capnographic analyzer in the industry for determining the respired CO2 content.

[0022]A nasal prong 13 protrudes upwardly from main body portion 11 and is positioned for insertion into a nostril (similar to that as shown at 14 in FIG. 7) to collect nasally exhaled breath of the subject 15. Nasal prong 13 is provided with an internal straight passage 16 which is in fluid flow communication with conduit passage 17 of suction port 12.

[0023]Oral prong 18 is directed downwardly through the main body portion 11 and is also provided with a straight conduit passage 19 having a distal opening 20 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com