Process for forming high-resistance slabs or tiles, intended for covering internal or external floors or walls

a technology of high-resistance slabs and tiles, applied in the direction of construction, transportation and packaging, building material handling, etc., can solve the problems of affecting the quality of the product, affecting the service life of the product, and not being very resistant to cracking,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example no 1

[0035]An example of this invention relates to the application to the lower surface of the ceramic slab or tile of a galvanized steel sheet having a modulus of elasticity of 200 Gpa and being 0.5 mm thick, using as a glue a polyurethane resin in a heated die at 70° C. The die is used to maintain the ceramic tile and the galvanized steel sheet positioned in relation to one another. Once the resin has completed hardening the product can be extracted from the die and subsequent cooling thereof to ambient temperature of 20-30° C. leads to a state of compression of the lower surface which enormously increases resistance to impacts thereof.

example no 2

[0036]By way of instance, consider the following example in order to provide a quantification of the results achievable with the process of the invention applied to a normal vitrified stoneware tile, format 60×60 cm having a thickness of 12 mm, water absorbance of 0.012%, a thermal expansion coefficient α(20-100)=7.5×10−6 K−1 and fracture strength 55 MPa. A tile of this type, when not glued to the floor, if struck by a steel ball weighing 510 grams from a height of 100 mm shatters into many shards. If the same tile is glued to the floor using a high-resistance glue (Mapei Kerabond) it can withstand an impact by the same ball from a height of 800 mm (Certifications et classements des produits du batiment—Revetementes de sol ceramiques—Cahiers du CSTB, cahier 3503 annexe 6 choc lourd—Janvier 2005). Beyond this height, the tile glued to the floor begins to dent, but does not break into fragments.

[0037]The same type of tile is glued under heating at 50° C. with a heat-fusible reactive p...

example no 3

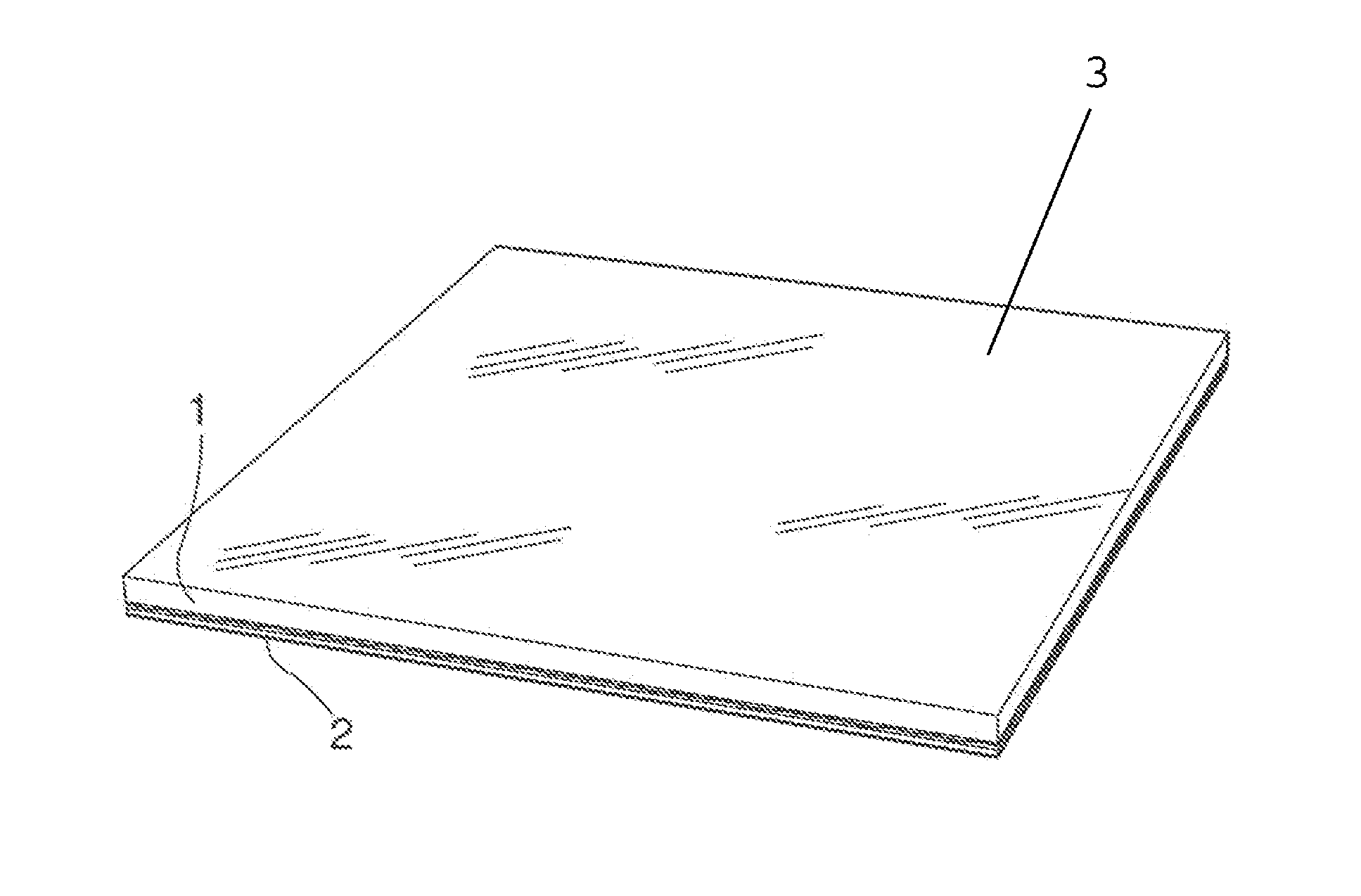

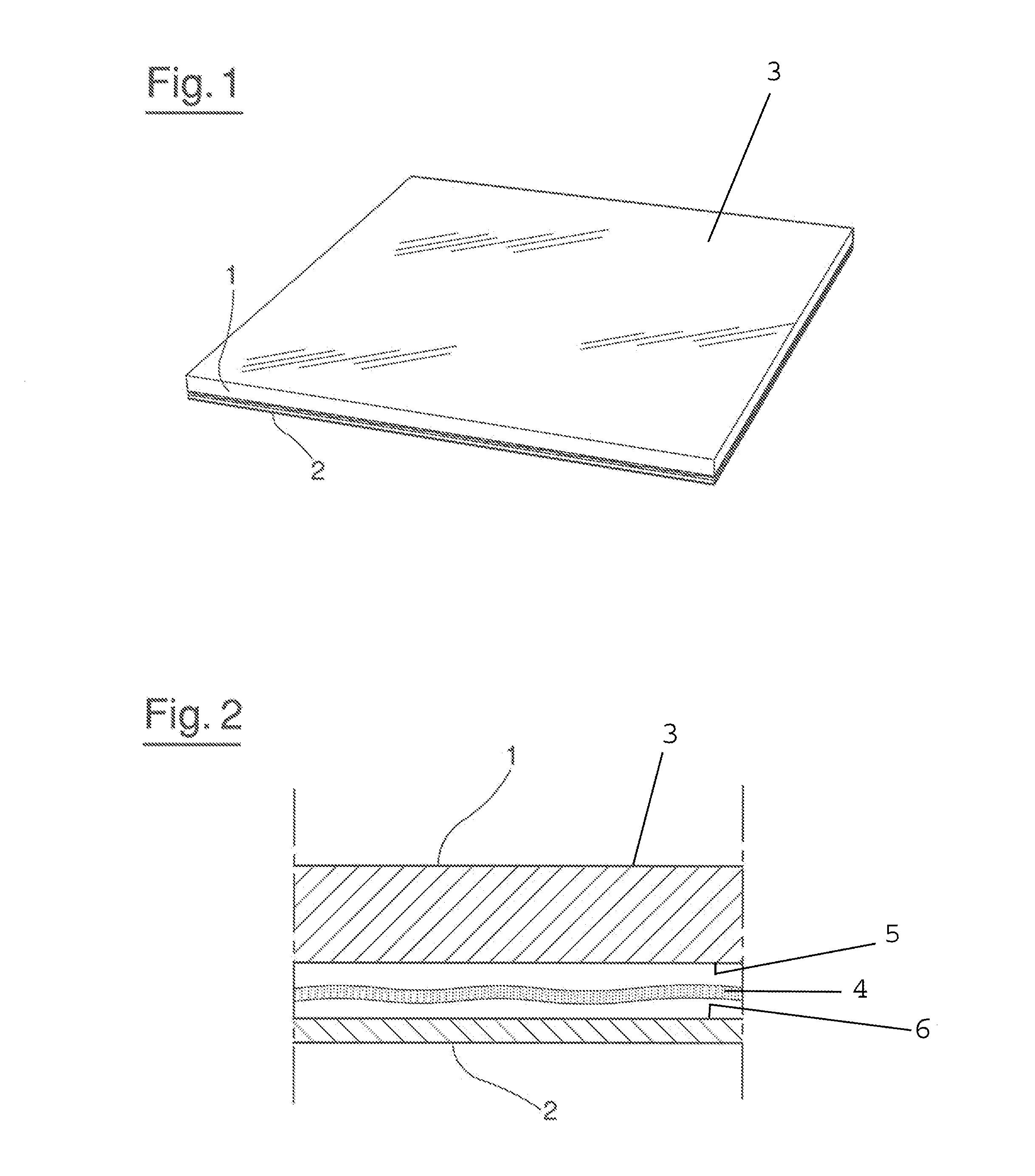

[0038]By way of example of application of the invention, consider the use of a ceramic slab or tile 1 having a 60×60 cm format with a thickness of only 3 mm made of unglazed vitrified stoneware. This tile has a water absorption of 0.01%, a thermal expansion coefficient of α(20-100)=7.2×10−6 K−1 and a fracture strength of 60 Mpa. When rested on the floor, it shatters if stuck by the steel ball weighing 510 grams which falls from a height of 50 millimeters. If the tile is glued according to the present invention on the floor using a high-resistance adhesive it can withstand an impact of a steel ball weighing 510 grams falling from a height of 800 mm. If the ball falls from greater heights the tile dents, i.e. is damaged by crushing.

[0039]The same type of tile is then, according to the process of the present invention, glued under heating at a temperature of 50° C. on an AISI 430 stainless steel sheet having a thermal expansion coefficient of α(20-100)=10×10−6 K−1, a modulus of elastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com