Golf ball

a golf ball and ball technology, applied in the field of golf balls, can solve the problems of golf balls receiving great shock and deformation, insufficient flight distance, short run, etc., and achieve the effects of low spin rate, excellent resilience performance, and low energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

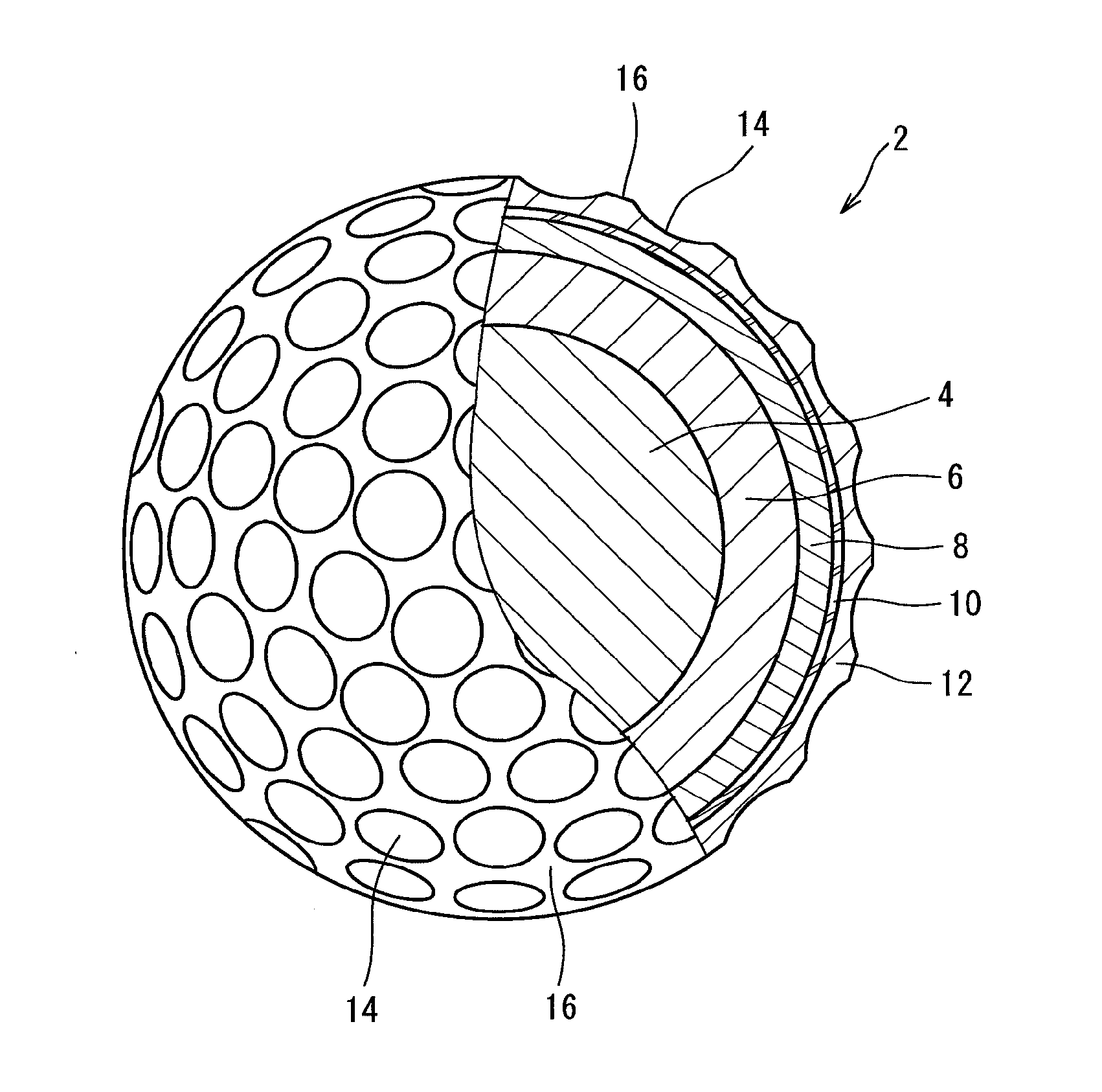

[0031]A golf ball 2 shown in FIG. 1 includes a spherical core 4, an inner mid layer 6 positioned outside the core 4, an outer mid layer 8 positioned outside the inner mid layer 6, a reinforcing layer 10 positioned outside the outer mid layer 8, and a cover 12 positioned outside the reinforcing layer 10. On the surface of the cover 12, a large number of dimples 14 are formed. Of the surface of the golf ball 2, a part other than the dimples 14 is a land 16. The golf ball 2 includes a paint layer and a mark layer on the external side of the cover 12, but these layers are not shown in the drawing.

[0032]The golf ball 2 has a diameter of 40 mm or greater but 45 mm or less. From the standpoint of conformity to the rules established by the United States Golf Association (USGA), the diameter is preferably equal to or greater than 42.67 mm. In light of suppression of air resistance, the diameter is preferably equal to or less than 44 mm and more preferably equal to or less than 42.80 mm. The ...

second embodiment

[0182]A golf ball 102 shown in FIG. 3 includes a spherical core 104, an inner mid layer 106 positioned outside the core 104, an outer mid layer 108 positioned outside the inner mid layer 106, a reinforcing layer 110 positioned outside the outer mid layer 108, and a cover 112 positioned outside the reinforcing layer 110. On the surface of the cover 112, a large number of dimples 114 are formed. Of the surface of the golf ball 102, a part other than the dimples 114 is a land 116. The golf ball 102 includes a paint layer and a mark layer on the external side of the cover 112, but these layers are not shown in the drawing.

[0183]The golf ball 102 has a diameter of 40 mm or greater but 45 mm or less. From the standpoint of conformity to the rules established by the United States Golf Association (USGA), the diameter is preferably equal to or greater than 42.67 mm. In light of suppression of air resistance, the diameter is preferably equal to or less than 44 mm and more preferably equal to...

third embodiment

[0256]A golf ball 202 shown in FIG. 5 includes a spherical core 204, amid layer 206 positioned outside the core 204, a reinforcing layer 208 positioned outside the mid layer 206, an inner cover 210 positioned outside the reinforcing layer 208, and an outer cover 212 positioned outside the inner cover 210. On the surface of the outer cover 212, a large number of dimples 214 are formed. Of the surface of the golf ball 202, a part other than the dimples 214 is a land 216. The golf ball 202 includes a paint layer and a mark layer on the external side of the outer cover 212, but these layers are not shown in the drawing.

[0257]The golf ball 202 has a diameter of 40 mm or greater but 45 mm or less. From the standpoint of conformity to the rules established by the United States Golf Association (USGA), the diameter is preferably equal to or greater than 42.67 mm. In light of suppression of air resistance, the diameter is preferably equal to or less than 44 mm and more preferably equal to or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com