Air Mover

a technology of air moving and moving parts, which is applied in the direction of lighting and heating apparatus, liquid fuel engines, heating types, etc., can solve the problems of increasing evaporation, affecting building performance, and exposing the building to water and moisture, so as to reduce drying time and increase evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

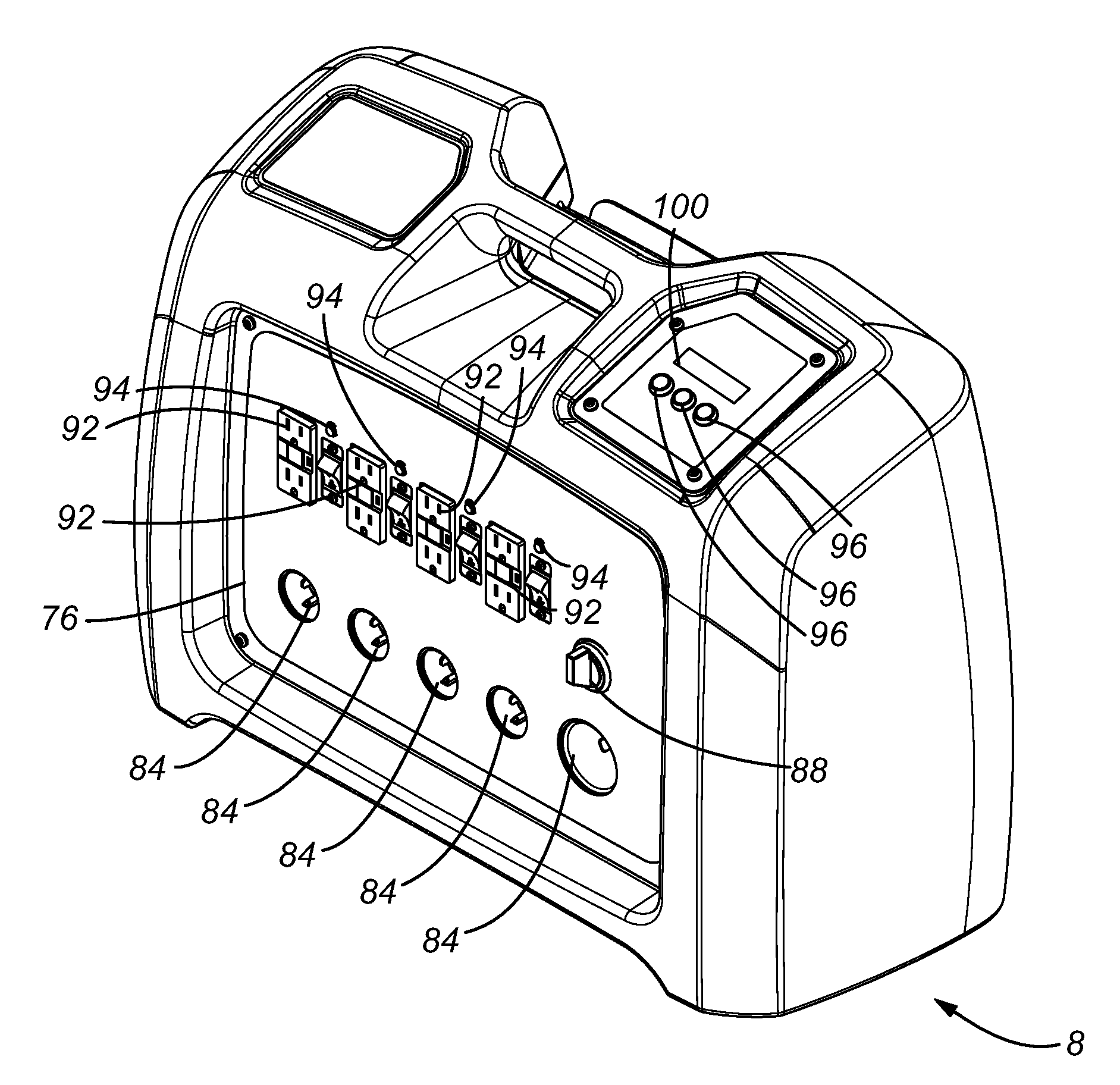

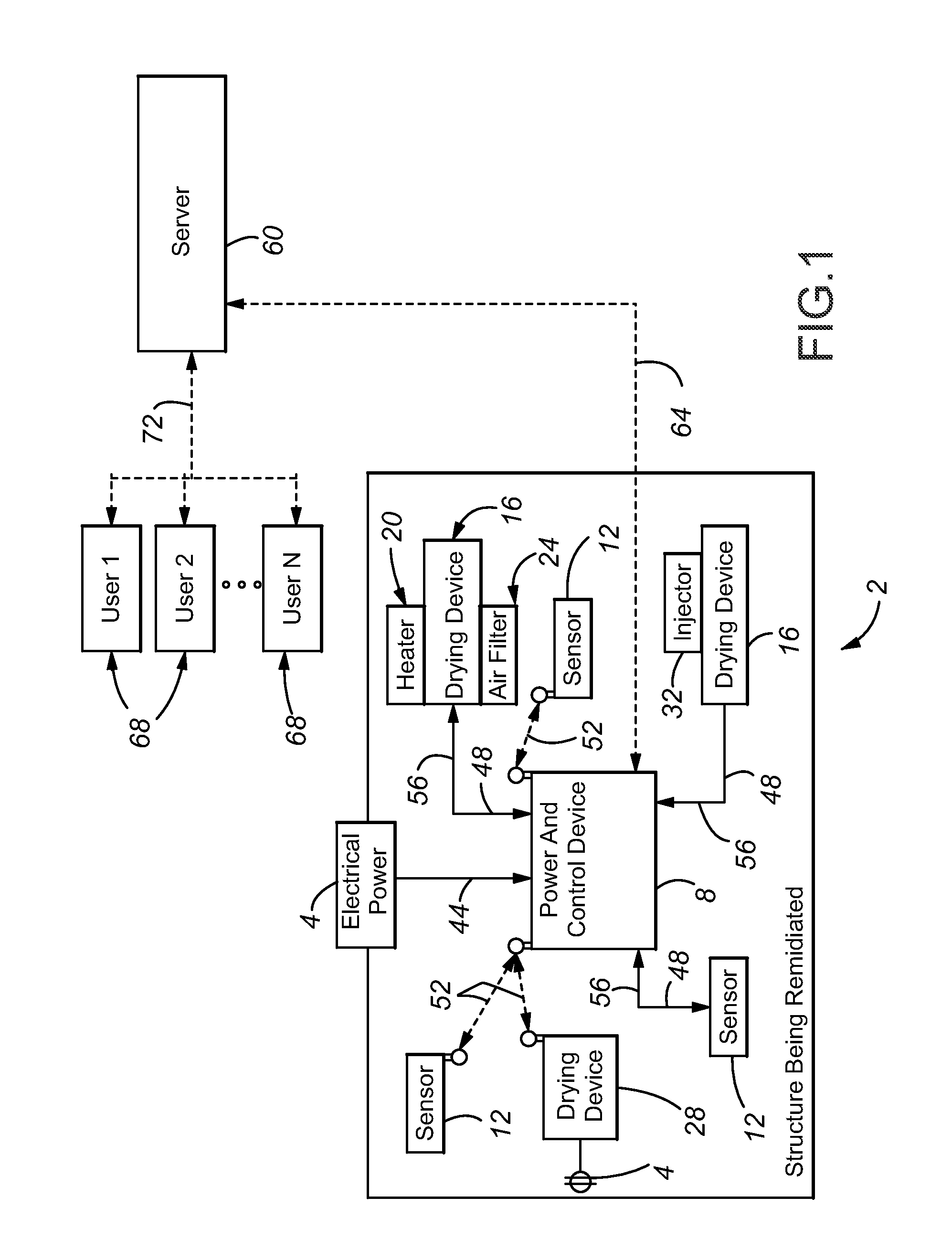

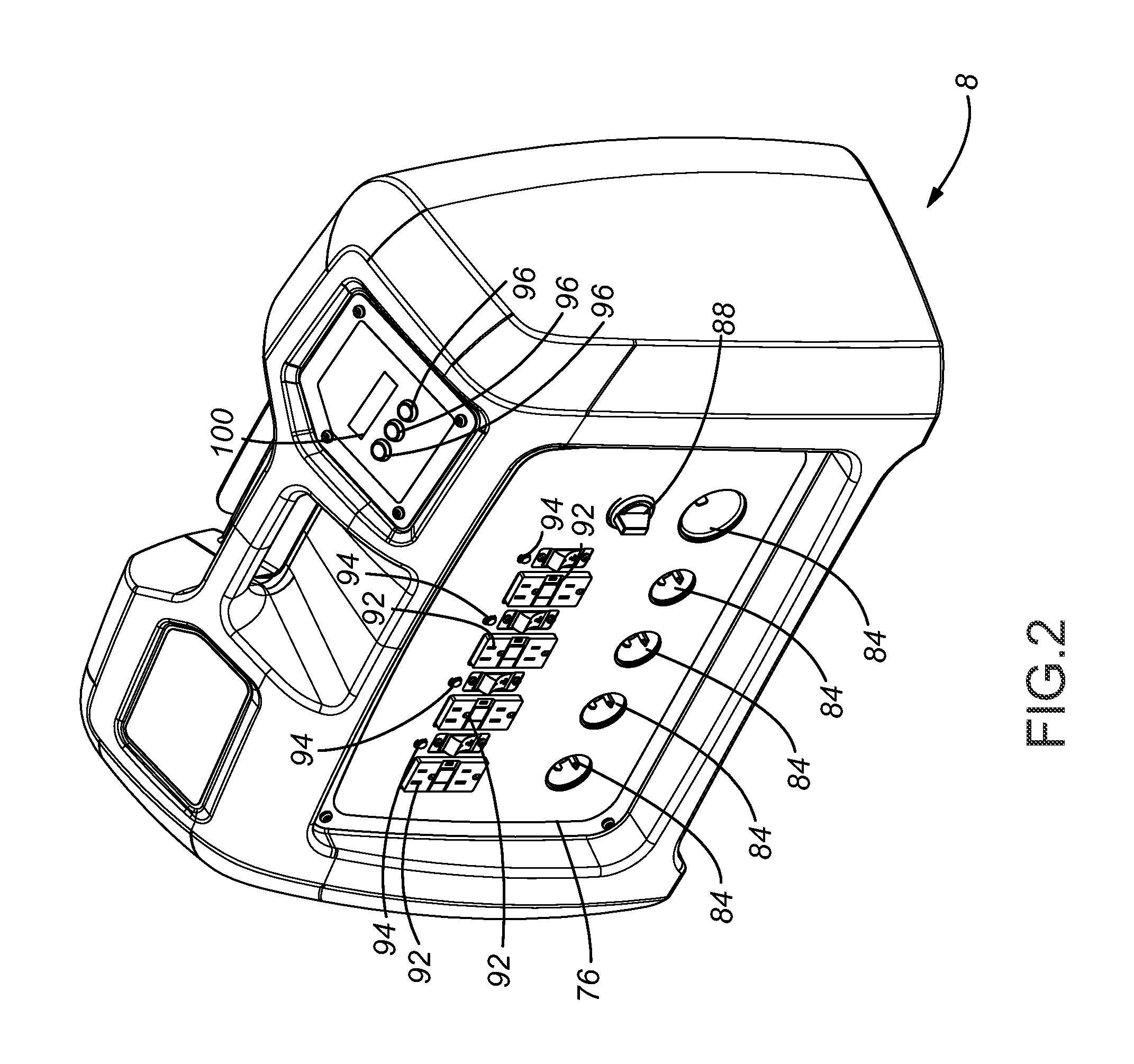

[0086]FIG. 1 depicts a general overview of major components that may be utilized with one embodiment of the contemplated remediation system. As can be seen, a building being remediated 2 typically will include various forms of electrical power 4. A power and control device 8, sensors 12, and several drying devices, which may include an air mover 16 (which may possess an integrated heater 20, air filter 24, or chemical injector 32), and a dehumidifier 28, are located within the structure 2. The drying devices may be connected to their own electrical power 4 and communicate with the power and control device 8.

[0087]Electrical power 4 is provided to the control device 8 through conventional wiring 44 from within the structure, such as 220 volt 30 amp or perhaps multiple of 110 volt 15 amp currents, or from another source, such as a portable gas powered electrical generator. The control device 8 may condition supplied electrical current to provide appropriate current to drying devices, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com