Programmable logic device and method for manufacturing semiconductor device

a logic device and semiconductor technology, applied in the direction of transistors, power consumption reduction, pulse techniques, etc., can solve the problems of inability to accurately estimate the power consumption of a semiconductor device manufactured based on a pld at the stage of testing the pld, and the operation delay and power consumption of parasitic capacitance between various wirings can also not be accurately estimated, so as to reduce the number of elements per bit in a memory array. , the effect of accurately estimated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

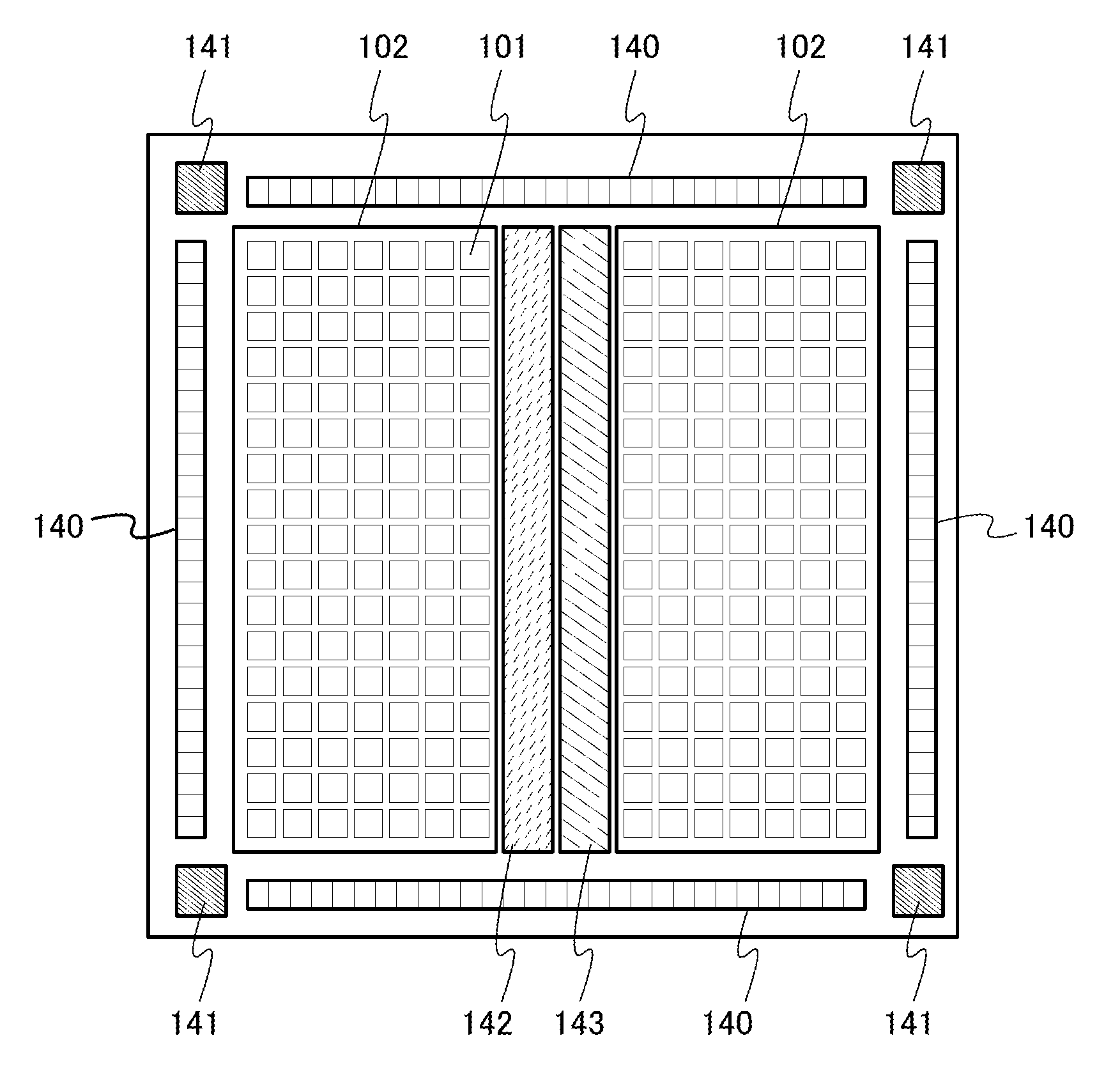

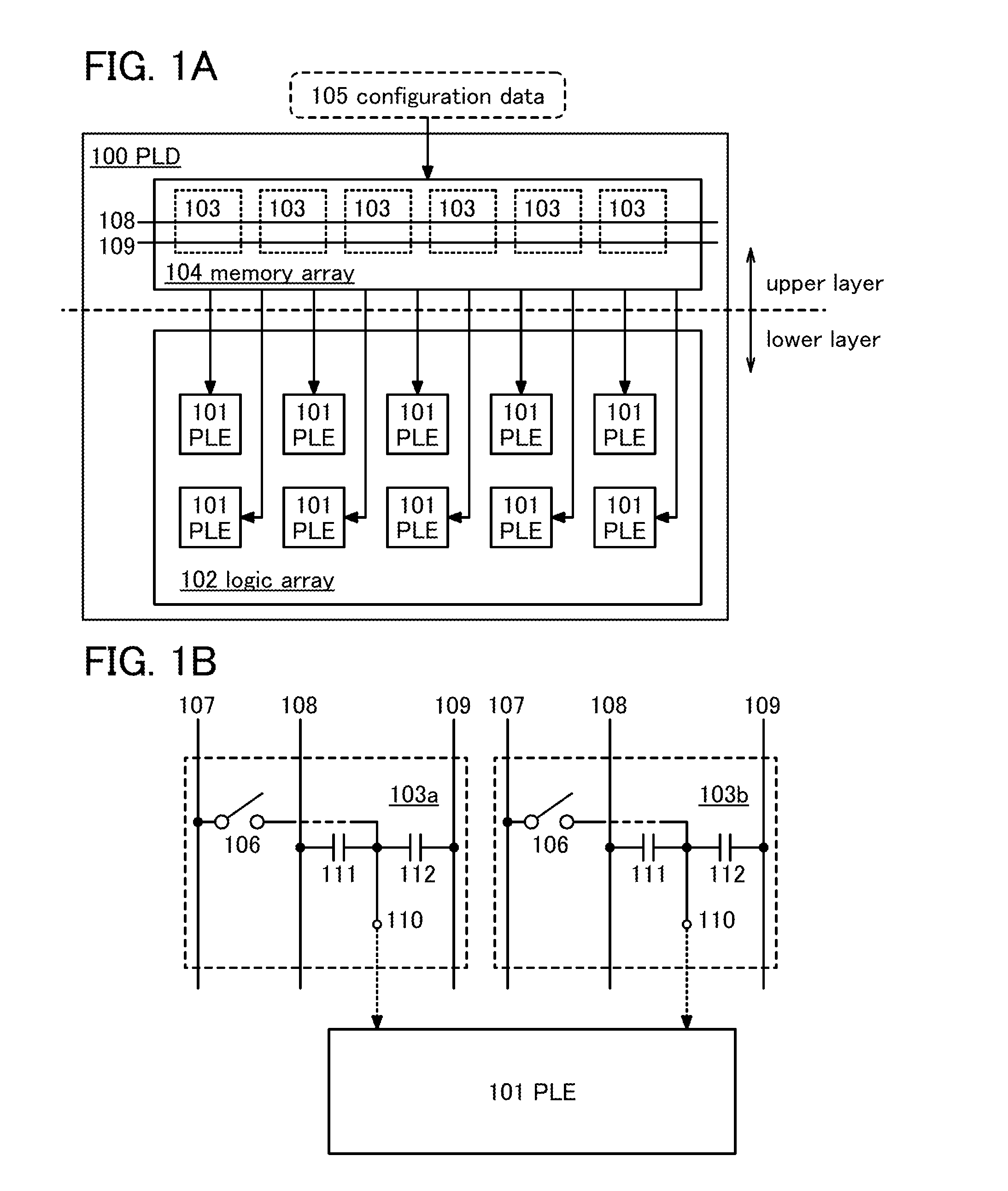

[0044]FIG. 1A schematically illustrates a configuration example of a PLD according to one embodiment of the present invention. A PLD 100 illustrated in FIG. 1A includes a logic array 102 including a plurality of programmable logic elements (PLEs) 101 and a memory array 104 including a plurality of memory elements 103. The memory array 104 is provided over a layer in which the logic array 102 is formed.

[0045]Each PLE 101 is a logic element whose logic operation, i.e., an output value corresponding to an input value, is determined by configuration data 105. Determination of the logic operation executed by each PLE 101 by the configuration data 105 results in determination of the function of a logic circuit that is configured in the logic array 102.

[0046]The memory array 104 has a function of storing the configuration data 105. The memory array 104 is provided with a plurality of wirings for supplying power supply potential to each memory element 103. FIG. 1A illustrates, as an example...

embodiment 2

[0119]In this embodiment, a configuration example of the memory array 104 is described.

[0120]FIG. 8 is a block diagram illustrating a configuration example of the memory array 104. Note that in the block diagram in FIG. 8, circuits in the memory array 104 are classified in accordance with their functions and separated blocks are illustrated. However, it is difficult to classify actual circuits according to their functions completely and it is possible for one circuit to have a plurality of functions.

[0121]The memory array 104 illustrated in FIG. 8 includes a cell array 160 including the plurality of memory elements 103 and a driver circuit 161. The driver circuit 161 includes an input-output buffer 162, a main amplifier 163, a column decoder 164, a row decoder 165, a switch circuit 166, a precharge circuit 167, a sense amplifier 168, and a writing circuit 169.

[0122]The input-output buffer 162 has a function of controlling input of various signals to be used for driving the driver ci...

embodiment 3

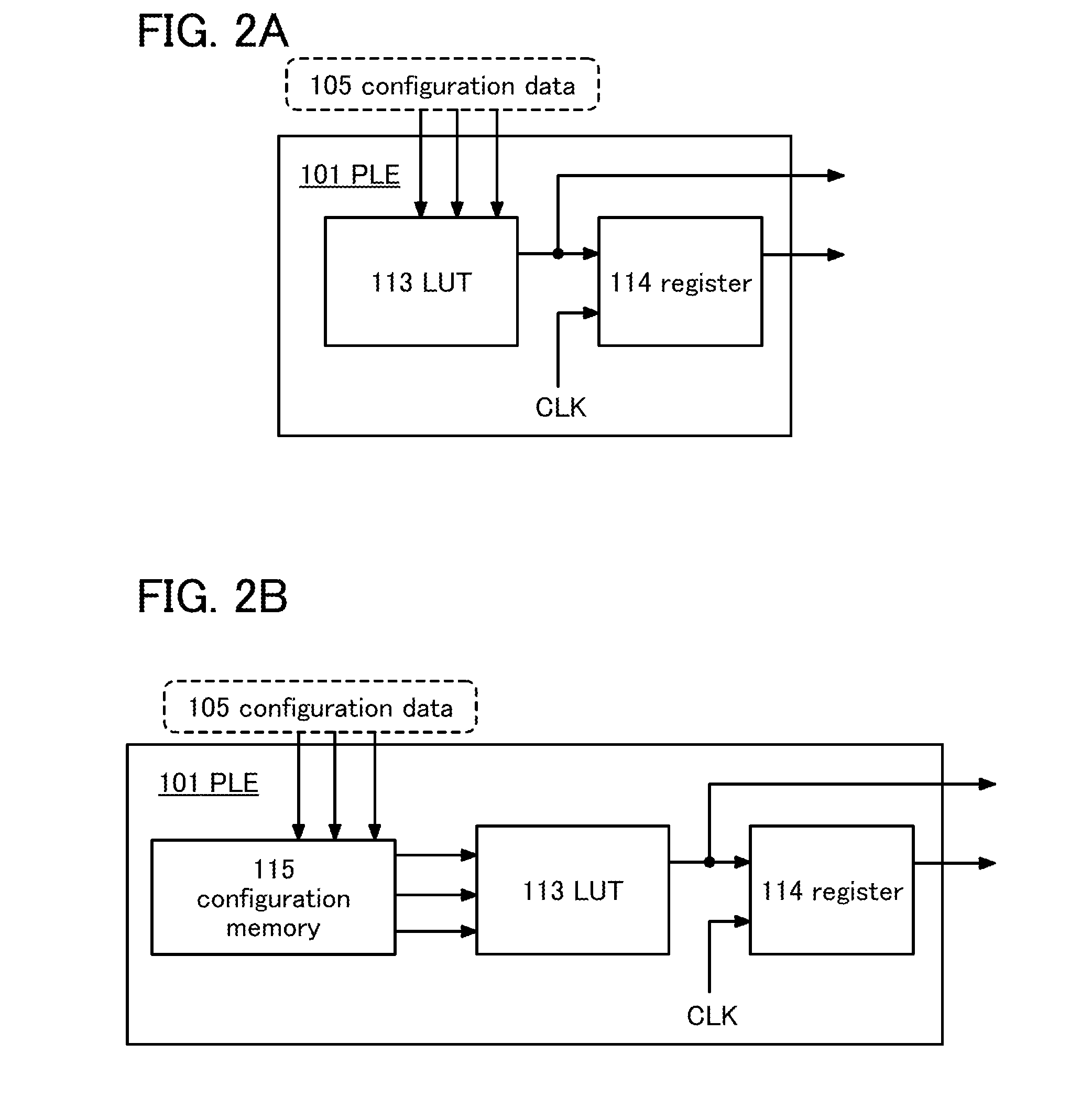

[0154]In this embodiment, a configuration example of the LUT 113 included in the PLE 101 is described. The LUT 113 can be composed of a plurality of multiplexers. Configuration data 105 can be input to any of input terminals and control terminals of the plurality of multiplexers.

[0155]FIG. 11A illustrates one mode of the LUT 113 included in the PLE 101.

[0156]In FIG. 11A, the LUT 113 is composed of seven two-input multiplexers (a multiplexer 31, a multiplexer 32, a multiplexer 33, a multiplexer 34, a multiplexer 35, a multiplexer 36, and a multiplexer 37). Input terminals of the multiplexers 31 to 34 correspond to input terminals M1 to M8 of the LUT 113.

[0157]Control terminals of the multiplexers 31 to 34 are electrically connected to each other and correspond to an input terminal IN3 of the LUT 113. Output terminals of the multiplexers 31 and 32 are electrically connected to two input terminals of the multiplexer 35. Output terminals of the multiplexers 33 and 34 are electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com