Heat dissipating device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

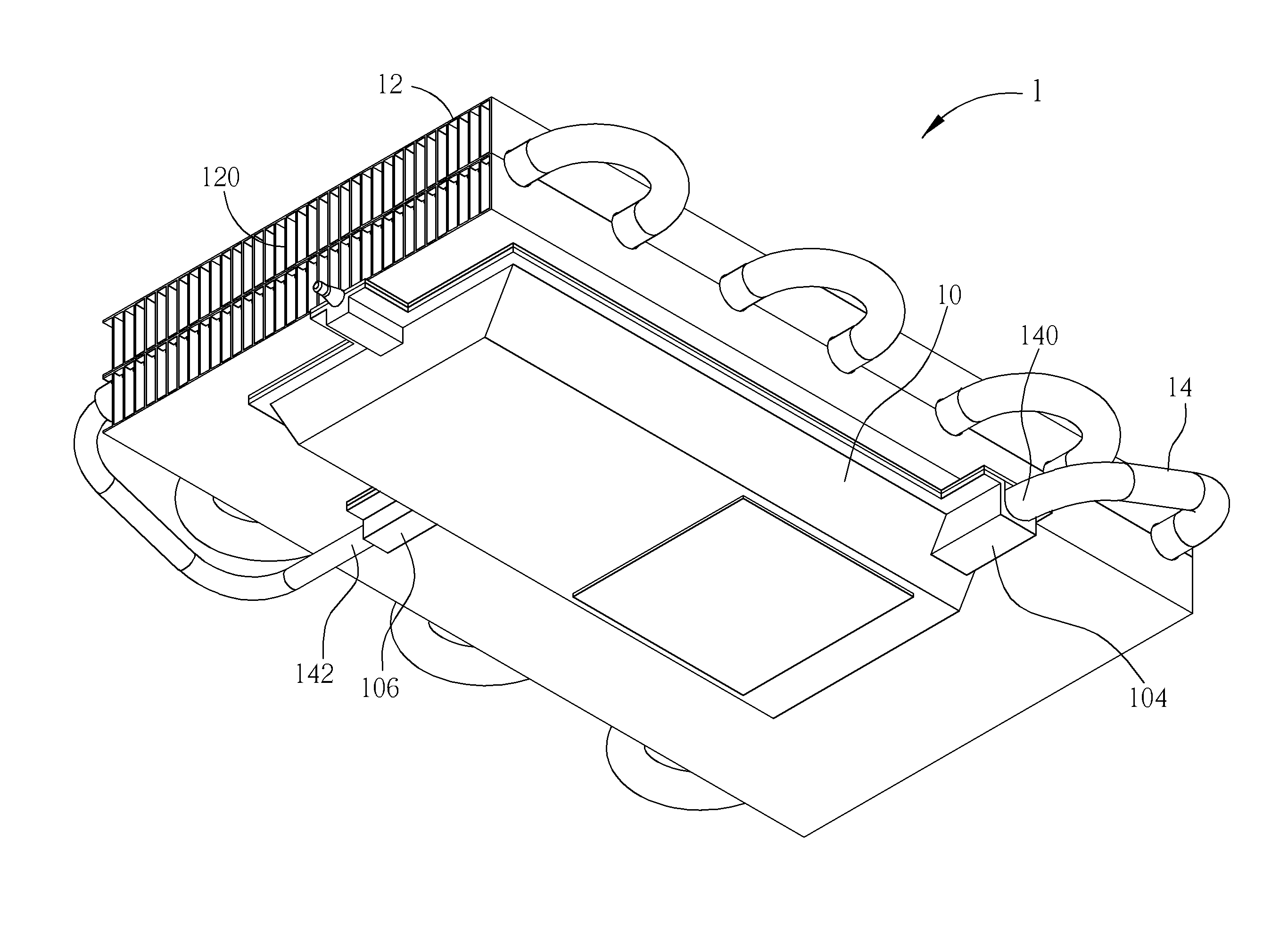

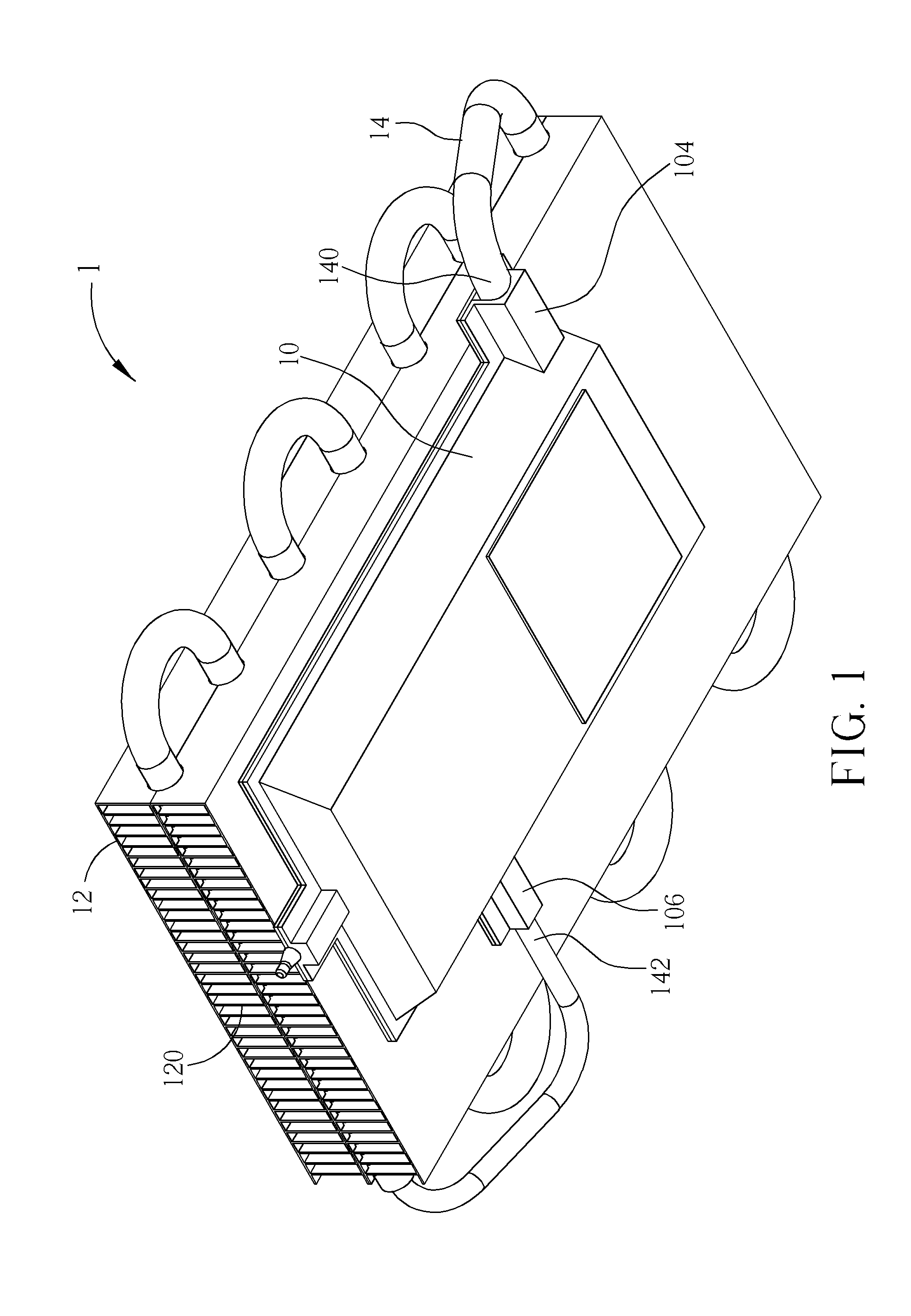

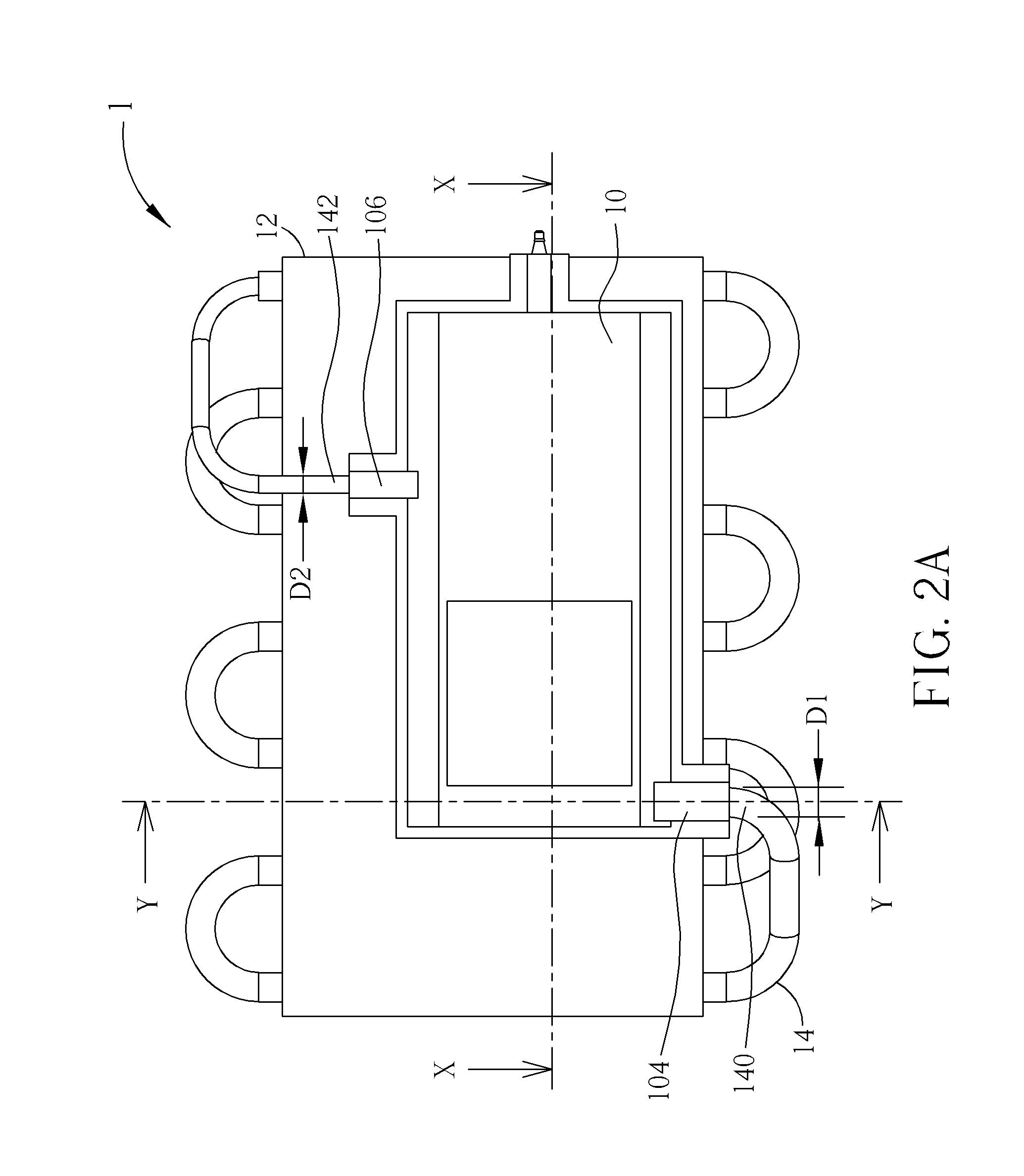

[0022]Referring to FIGS. 1 to 3, FIG. 1 is a perspective view illustrating a heat dissipating device 1 according to an embodiment of the invention, FIG. 2A is a top view illustrating the heat dissipating device 1 shown in FIG. 1, FIG. 2B is cross-sectional view illustrating the heat dissipating device 1 along X-X line shown in FIG. 2A, FIG. 2C is a cross-sectional view illustrating the heat dissipating device 1 along Y-Y line shown in FIG. 2A, and FIG. 3 is an assembly view illustrating the chamber body 10 and the first capillary structure 16 shown in FIG. 2B from different view angles.

[0023]As shown in FIGS. 1 to 3, the heat dissipating device 3 comprises a chamber body 10, a heat sink 12, a pipe 14, a first capillary structure 16, N vapor channels 18 and a vapor collecting space 20, wherein N is a positive integer. The chamber body 10 has an evaporation chamber 100 and a compensation chamber 102, wherein the evaporation chamber 100 has a vapor outlet 104 and the compensation chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com