Puffing Apparatus For Producing Cereal Crackers And Methods Thereof

a technology of puffing apparatus and cereal cracker, which is applied in the field of puffing apparatus for producing cereal crackers, can solve the problems of affecting the quality of cereal crackers, and consuming a lot of energy, and achieving the effect of reducing the number of puffing apparatuses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

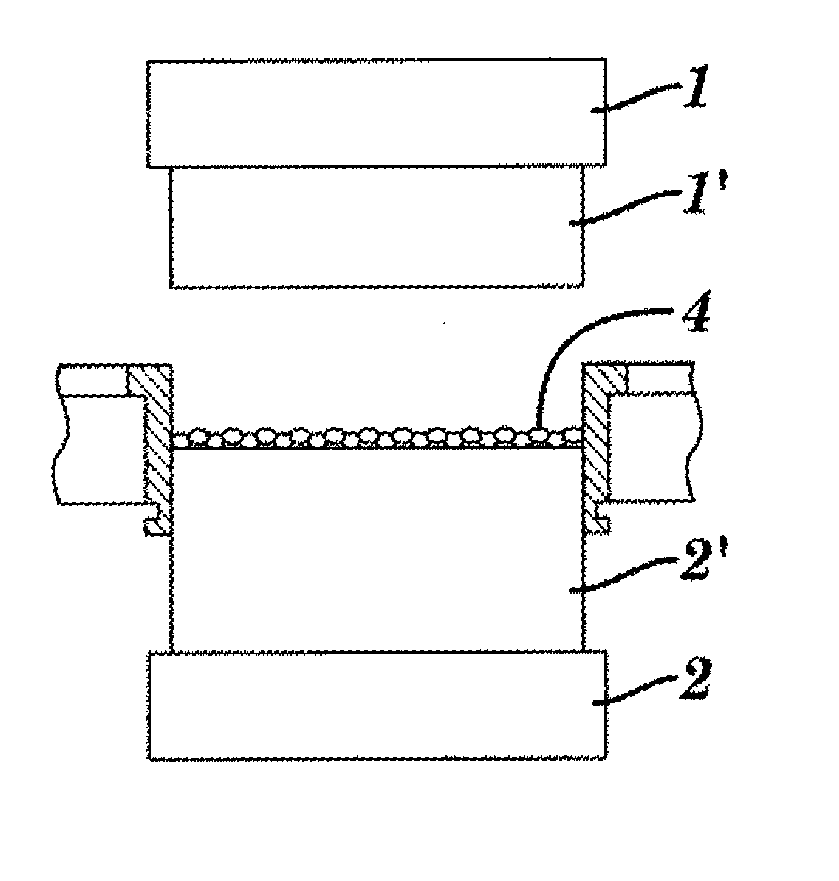

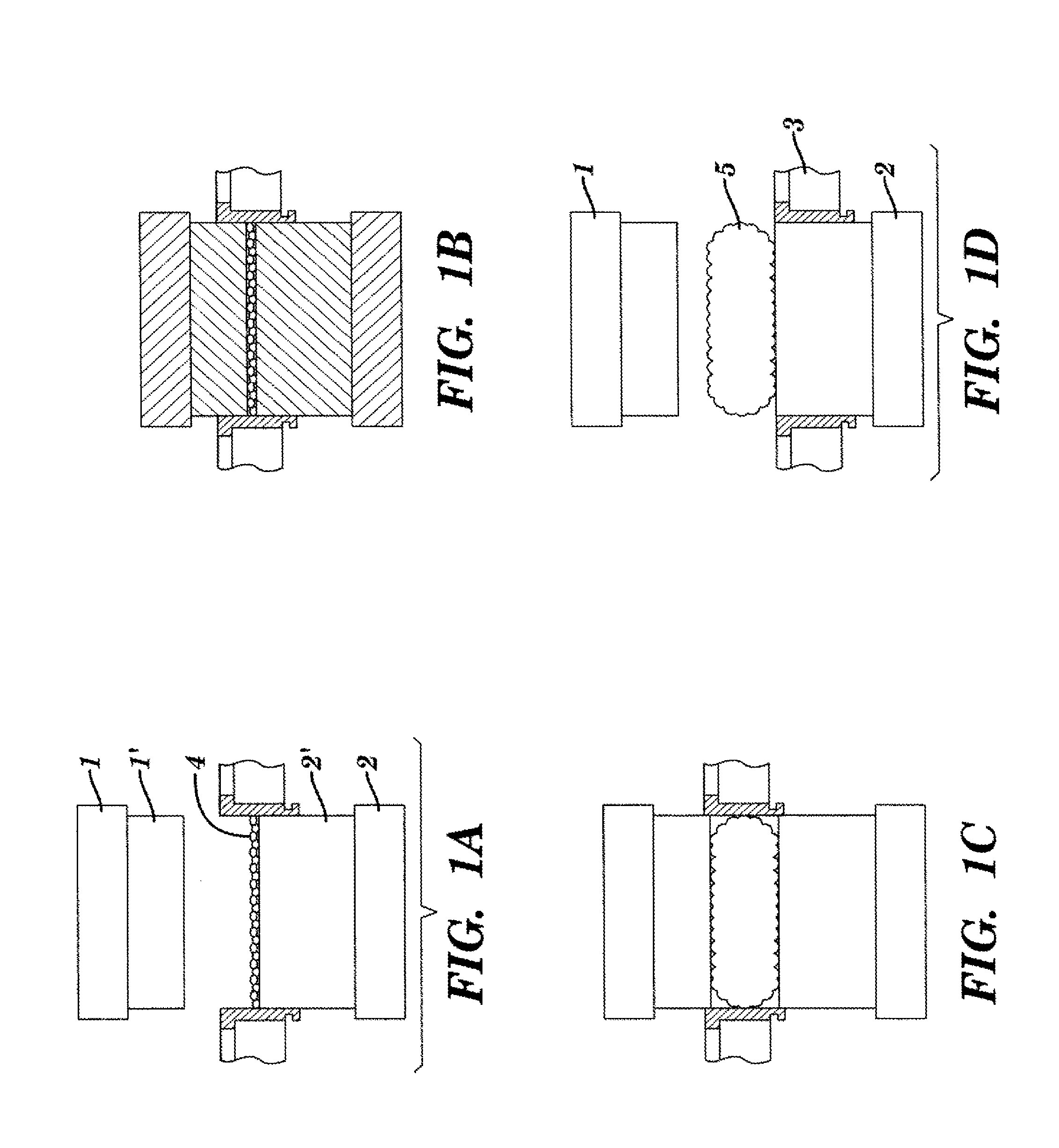

[0033]Referring to FIGS. 1A-1D, important mold position steps in the process of producing a puffed cereal wafer or cracker are shown. The mold comprises an upper mold 1 and a lower mold 2, both heatable by means of embedded heating elements (not represented) and movable upwardly and downwardly by being directly driven by hydraulic cylinders as illustrated and explained below. Upper and lower molds generally have punch elements (1′,2′) which are slidably receivable in a ring mold 3 (preferably fixed but not always required) so as to form therewith a hermetically sealed molding cavity. In FIG. 1A the mold cavity is open and provides a feeding cup for dropping food-starch containing raw material 4 therein by lower mold 2 having been partially retracted within ring mold 3 while upper mold 1 is lifted.

[0034]In FIG. 1B shows pressure-baking of raw material 4 being crushed, compressed and heated in a closed cavity by descending the upper mold into the ring mold and then pressurising either...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com